Since the very beginning of the project (even before the kickstarter launched), it’s been pointed out that if we made the router bit the center of where the chains anchored it would massively reduce the amount of computation needed to compute the sled’s position and make calibration much easier. If the router bit is the center of rotation, then the math reduces to a very simple case where we’re finding the tip of the triangle knowing the length of three sides.

There are other positive benefits to having the sled set up this way, like that the sled orientation doesn’t matter (it rotates around the bit) which would in theory make reducing friction between the sled and cutting surface less of an issue. Torque from the bit twisting the sled also becomes less of a concern, because the sled rotates around the bit.

I’ve always been on board with the idea, but it didn’t seem practical to me from a physical construction stand point. Most of the ideas I heard thrown around for how to do it relied on large bearings like these:

While I’m sure these bearings would do a fantastic job, I thought adding them and the associated hardware to mount them and attach the chains would increase the cost of the machine too much to really be affordable anymore.

Another concern I had was how long bearings would last in the very dusty environment right around the router.

I put the center rotation idea in a the category of “great idea, probably going to be a common modification”, but I had an idea last night that I think could make moving the center of rotation of the sled to the router bit possible.

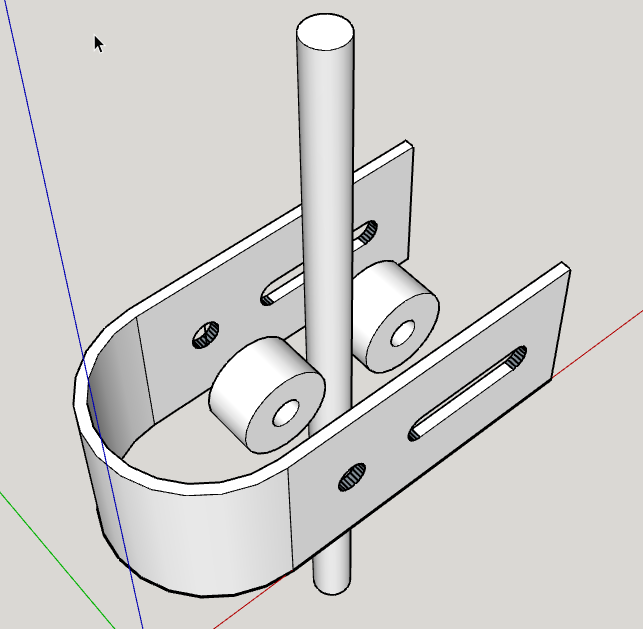

The idea is to use a curved piece of rolled steel stock as a track on which the ends of the chain can run like this:

It’s pretty cheap to build, and seems pretty hearty. I just threw this one together this morning from parts from the hardware store (The bent ring was made by wrapping that piece of steel around the forklift’s propane tank). So far it seems promising, but not 100%. The biggest issue I’m seeing right now is that pulleys I got from the hardware store use a brass wheel inside that rotates around a very loosely fitted pin and under load they seem to want to bind up. Something with real sealed bearings would be a big step forward I think.

I’m going to go see if I can find some better pulleys and do more testing. I wanted to put the idea out there to get feedback and see if everyone can see any ways to improve the idea.

- not truly zero, but near enough to zero.

- not truly zero, but near enough to zero.