Got a 3watt laser connected and working on the maslow machine, so pumped!! The m106 and m107 commands for laser on/off works great. Only trouble I am having is adjusting the strength of the laser. Does maslow gc read the s commands for laser strength?

good job. makermade got a laser going might want to ask them. or put a github request in for the coders to respond to.

no, neither GC or the firmware handle S or any other way of setting spindle

speed/laser strength

David Lang

What about the grbl port?

I haven’t tried it, but since grbl supports lasers, it should have the support

you need

I hope you ascribe to the saying ‘there are no stupid questions’ because this might seem to be one…what is grbl?

Would all you need to do is PWM control one of the spare IO pins?

Ok, I have maslow ground control on my computer (linux mint), and the firmware directed by maslow website on the arduino running the motors. Where does grbl fit into this?

grbl is a different firmware that runs on a different model of arduino. There is

a fork of it that can control the maslow hardware. Since grbl is a general

purpose firmware, it has the ablity to control a laser, where the maslow

firmware doesn’t.

So if you are interested in creating a laser maslow, starting with the grbl

firmware and learning it is probably going to be easier than modifying the

maslow firmware to support a laser

David Lang

I think you might already be able to control the laser with the S command. If not it wouldn’t be very difficult to add. Do you need a PWM output based on the value of S? What value for S corresponds to 100 duty cycle?

Send us pictures!

Just chiming in… the “s” would be range 0 - 255 Pwm . This is a typical laser intensity control.

I have several lasers working on Mach3 and Prusa I3 platforms.

So we would want the command “S255” to correspond to the maximum PWM value, not for example “S100” for 100%?

I guess what I am getting at is what does the gcode actually look like to control the laser. If someone posted a sample of gcode to control a laser it might help us to implement it correct.

in grbl you set the max speed of the spindle, and then it scales the S parameter

based on this.

so if you set the max speed= 100 then s50 is a 50% PWM signal, but if you set

the max speed=10000 then you would need to do s5000 for the same PWM signal

The max speed is set with a $ parameter (I’d have to look up which it is)

David Lang

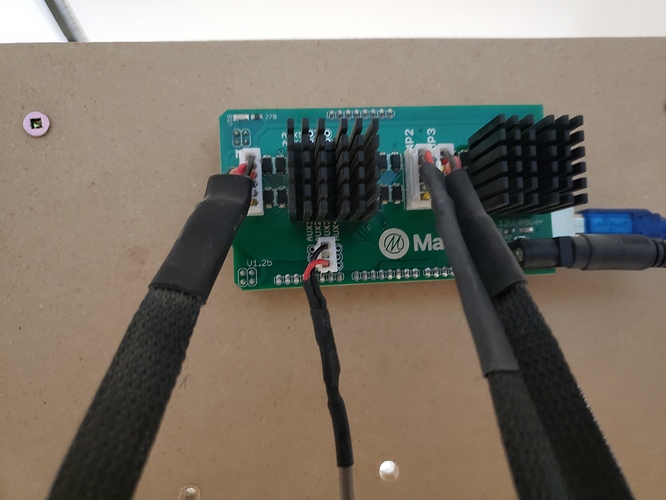

Couple pics of my setup:

2nd pic- rigid router mounted (pretty standard).

1st pic- laser mounted. I fastened laser inside 3" abs so I could use router base to hold it. Works great for switching between router and laser.

Close up of laser mounted in abs pipe. The blue rings are from 3" caps for abs, they worked for the pipe to fit router mount.

This would be great if it can work without having to change programs one is working with. I will post sample of gcode once I get a chance.

note that if your mount isn’t the same weight as the router it’s replacing, you

will have some additional inaccuracy in your system (unless you calibrate it

with the laser)

David Lang

circle.gcode (734 Bytes)

heres a sample of the gcode for laser cut circle at full power.