I am wondering if there’s measurements available for riser’s in horizontal setup on concrete slab. So to keep belts level for 3/4 mdf with 3/4” spoil board. I also have dxf files I need to convert for boat jig I’m am trying to cut from the 3/4 mdf. And while I’m asking. Anchor point measurements for accurate cutting on 4x8 sheet

You need quite a bit of footprint if you want to cut a WHOLE 4x8. I went too small to start with and I got jiggly weirdness on the far edges. Once I set new anchors things got better.

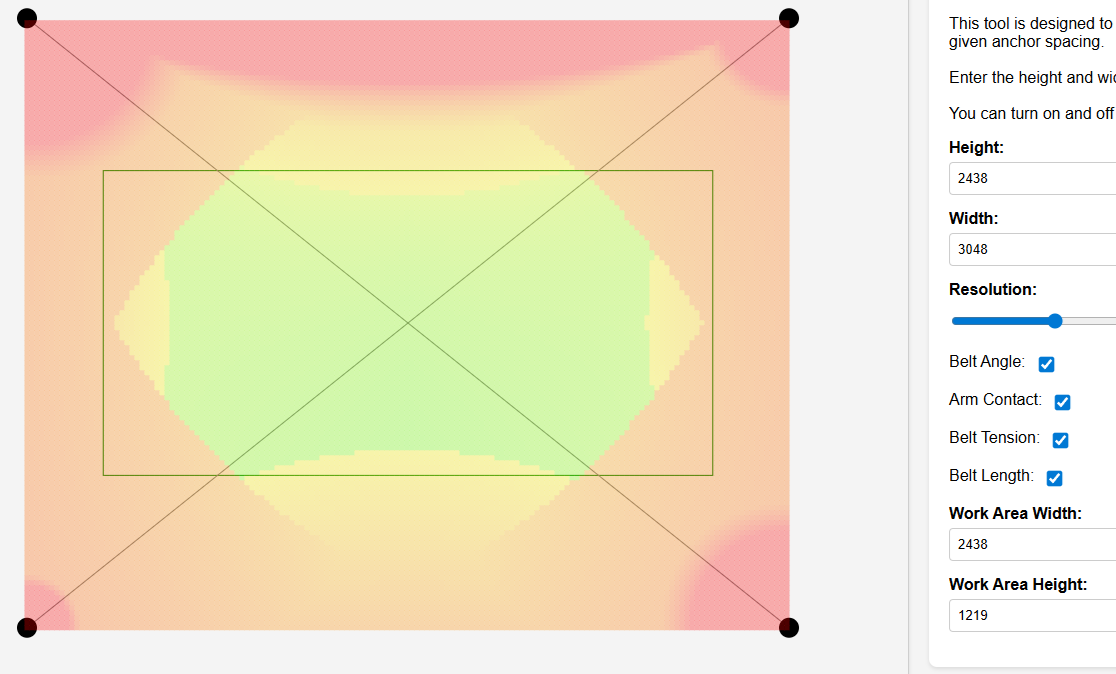

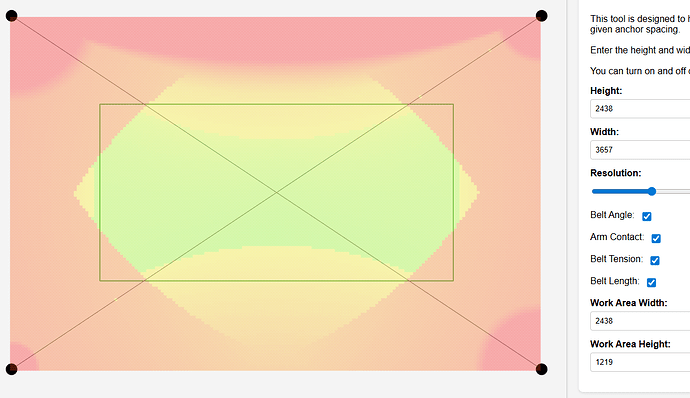

2440 x 3700mm isn’t big enough. 3100 x 4100 seems to be big enough, but I have not cut all the way to the edge yet! I’m working on my linear distance correction right now.

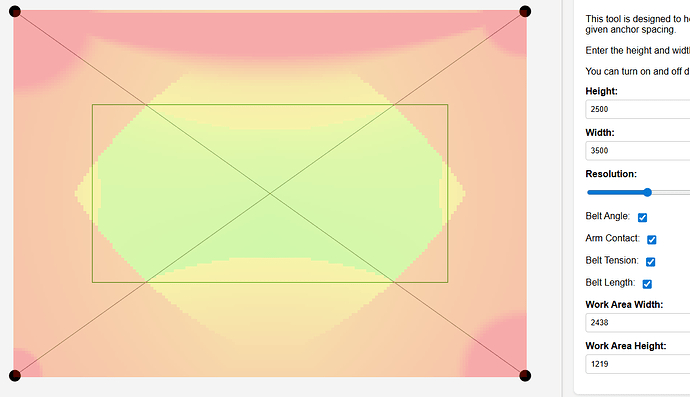

Run this model:

I still have tiny areas of “not green” on the corners for my second set of anchors.

3100 x 4400 would get all green, if you have the room. The belt length is still OK.

Argh. I should have done that… Oh, well. ![]()

Yeah, that’s 10’ 2" x 14’ 5"! At least we can still park on top of that area!

Could be helpful to see approx belt length displayed on the simulator, along with a warning if dimensions are too long for the belt lengths included in the kit.

Thanks for sharing, am trying to figure out recommended dimensions for my setup too. Will post my overall dimension questions in my build topic since O.P. here seems to be curious about height of anchor mount risers.

Am guessing as long as the belts clear the antislip+spoil+stock height high enough to not snag belt on the edges, then, they’re high enough.

Am expecting people keep anchor mounts as low as possible to the slab. Am guessing low anchors with delta in Z height of belts from anchor height to arm height will contribute to less overall inaccuracy, than, inaccuracy contributed by taller anchors (that may pivot/move if not rock solid…) matching the arm heights to minimize belt’s Z delta.

In other words… if you can’t make and fasten rock solid anchor mounts matching height of the belt arms, then, make anchor mounts as low as possible that still clear top of stock height (accounting for belt sag over longest distance).

Someone must have numbers/opinions on this, this is the internet after all ![]() ?

?

EDIT: I just read 1st post again, “Anchor point measurements for accurate cutting on 4x8 sheet”. Neat, am curious about best practice recommended dimensions too. So… I looked at…

- Building the Frame — Maslow

-

Attaching to the Floor — Maslow

- “roughly rectangular shape 8’x12’ (2.5 x 3.5m).”

-

-

Shows wood frame design 8’ x 10’ (2438.4 x 3048)

-

“If you have room you can use 12’ 2x4s to get even better performance”

- 8’ x 12’ (2438 x 3657)

-

-

- Can’t see recommended dimensions, so am ASSuming wood frame dimensions would be used.

Am still curious, for garage slab setup, needing 10’+ anchor width spacing to allow car to clear (since garage door is 9’ wide). What’s the recommended spacing for holes (I only want to drill once ![]() ), given the kit’s belt lengths, and given the balance of belt force/accuracy and minimal overall slop/inaccuracy we’re striving for?

), given the kit’s belt lengths, and given the balance of belt force/accuracy and minimal overall slop/inaccuracy we’re striving for?

Thanks @WeldingRod this was information I needed. Are you using belt to floor or did you try to keep belt level

@AzaB2C i am trying to accomplish same thing. I have 1 car garage that doesn’t get parked in its storage for most part. But there’s space for the dimensions welding rod posted I going with them

I went with all the anchors at the same height, based on the super-long M14 bolts I used. I just put PEX pipe sleeves on the bolt. They are roughly the same height as the spools; some higher, some lower. I measured and put in the numbers.

Sorry, level-ish.

BTW, the belts don’t visibly droop.

PEX sounds like a neat idea, have some 1/2" inside diameter leftovers. Cheers!

Thought M10 is needed? Anchors that came with my 4.0 kit have ~10mm inside diameter, no additional anchors in 4.1 upgrade kit..

I 3D printed larger belt ends. The PoolZilla anchors are M14.

Here’s a walkthrough of my process for picking my anchor point locations for a 1 car garage:

I’ve been using this setup for a while now and I’m super happy with it

Aza’s Built to Code wrote:

Could be helpful to see approx belt length displayed on the simulator, along with a warning if dimensions are too long for the belt lengths included in the kit.

http://www.lang.hm/maslow/maslow4_frame.html shows the required belt length.

David Lang