P.S. I holed my Eastport Pram on a small rock on Green Lake in Seattle by just coming in a bit hot with my wife seated on the bow. It was an easy fix, but still a testament to how puncture-resistant 1/4" plywood is, even glassed.

I have been building stitch and glue boats for a while. To say my jigsaw skills are still nothing to write home about I figured Maslow was the answer even if it takes a couple of hours to do a layout from plans to a cutable file. Can anyone offer an easy 2D program to do a layout in that a novice can learn?

You mentioned a jigsaw, if you are cutting out parts marked by a batten, a circular saw does wonders for curved lines, just set the depth to one tooth deeper than the plywood you are cutting.

On the other hand, it’s marking out the lines by a batten I can’t stand, nothing like a cement floor (and lack of space) to ruin that experience. Just got my Maslow kit, should have started the frame build.

-

I don’t use a jigsaw, they wander too much. I use a Japanese pull saw. They have a super thin kerf and you can follow a pencil line perfectly. I cut both of my boats out with this and it was worth the effort.

-

There are several free 2D CAD programs (e.g. DraftSight, TinkerCAD, etc.) that are easy to learn. They all export DXF files. All you’re basically doing is loading data points and connecting them to make straight lines or curves.

-

I’d be wary of a large circular saw, but they now have the small versions with the 3-4" blades that may do the trick (see #1 above). Power tools can make a difficult job easier, but they can also do a large amount of damage in less than a second.

That is just a skill that you need to learn, i can follow a pencil line perfectly with my cheap jigsaw.

Though i really love my pull saw as well.

I agree and good for you, but is that really a skill you want to learn while cutting boat parts from a $90 sheet of 1/4" marine grade plywood?

Personally, I’d always get the measurements right in CAD and trust a machine to do the cutting (one time, or many times). It’s the perfect extension of “measure twice, cut once”.

Every set of plans is different. For example, the plans that I got from CLC had full-sized drawings of the parts, so there was no measuring needed. I just rolled out the paper on to the plywood and started marking on the lines with an awl. It would require a ton of measurements off the plans into CAD for me to be able to cut out a Passagemaker with a Maslow.

If you get a set of 8-1/2" x 11" plans with a diagram of the measurements, that’s another story. A quick check though is if the parts look “fair”, meaning the curves are smooth. That’s why I mentioned Bezier curves.

Actually, what @Sonny_Lacey did for his Bobcat probably required a ton of measurements too. In order to even be able to cut out his boat with his Maslow, he had to either “take off” measurements from drawings or transfer measurements or “offsets” from the plans into his CAD program.

Hi all!

Yep: I had to transfer all of the offsets from Payson’s Bobcat plans into Fusion360. The great thing is that Payson already had all of the offsets in the drawings (so many inches to the right of a ‘zero’ axis, so many inches up from that plane)… It was fairly simple and fast to put them into F360 using points and calling up the (d)imension tool to get it in the correct X,Y place. I then connected the dots, so to speak, with either bezier or straight lines, depending on the plan.

Not all plans are so detailed…for instance, my good ‘ol CLC Northeaster Dory was just a set of full-sized plans that would have necessitated me measuring each point and creating such an offset. It was easier in that case for me to just put the plans on plywood, awl through and connect the dots with pencil and batten and cut with my Skilsaw. I liked Payson’s sheets of smaller (1.25" = 1’) scale plans, which I could lay out right next to my laptop and refer to. Full-size plans would just be a hassle, and I think CLC only has full-size plans…

Sonny

I’d like to build some small boats to be powered with electric trolling motors for me and a couple friends to cruise around and maybe fish out of. I’ve had a dream of having a mini fleet of these since seeing Chloroplast boats like this: https://www.portableboatplans.com/composite-cruiser.php

Goals -

Cheap: I want these things to use a sheet or two of plywood a piece, and then we will paint or coat them. They will not be stored in the water and will be used very infrequently, so spending extra on marine grade wood will likely not be done. I have a couple electric trolling motors already that I’ve been picking up at yard sales as I’ve come across them.

Weight capacity: I have a couple bigger buddies, so 300lbs (maybe 325lbs to be safe with the battery+motor) will need to be able to be carried. This is a big sticking issue for most of the designs I’ve seen, as they have a max 200lb or 250lb rating.

Fun: Obviously with a trolling motor we are not going to be breaking any speed limits, but I’d like to maximize the design for fluid dynamics, even if that means tricky cuts, because the robot will be doing that anyway!

Has anyone else had similar ideas or has worked on a project like this? I’d love to hear about it or get plans if you have any!!

That sounds like a very cool plan! I used a jet-ski battery and a trolling motor on my 8’ Eastport Pram for several summers. It was great to take the family or my son and some of his friends out for a spin on the lake. I could get about an hour on one charge.

The boats in your link are designed with very simple straight cuts, which really wouldn’t take advantage of a Maslow. You mentioned wanting to maximize the design, even if that means tricky cuts, which probably means a pretty serious departure from the boats in the link. For efficiency, you’re probably going to want a boat with a finer entry than just a bluff bow transom (unless your bow transom is out of the water entirely, due to the rocker). With that being said, there are plenty of great boat designs with a hard chine and a bluff bow (e.g. San Francisco Pelican). This approach may also help with stability since you mentioned some bigger guys using them.

You may also need to explore the flat bottom vs. V-bottom approach. They both have their pros and cons. There are lots of one, two and three sheet boats out there on the Google, you just have to find them and compare their characteristics. The challenge is that this is a niche market for boat builders, so there may not be a ton of reviews on the performance of the various boat designs.

Good luck and keep us posted!

It’s been a minute since I discussed boats that one could CNC and we’ve been discussing boats with bluff bows and hard chines for reserve buoyancy on another thread. You can’t really have that discussion without mentioning the San Francisco Pelican or it’s siblings the Great Pelican and Pacific Pelican. The original SF Pelican was designed by Bill Short specifically to be able to handle the blustery conditions on San Francisco Bay. I taught sailing there for three years and can attest to how exciting it can get. It was also designed to be easily home-built, in fact, I’m not aware of any company that produced these. EDIT: I forgot that Smith Brothers (of El Toro fame) built Pelicans on Samish Island, WA.

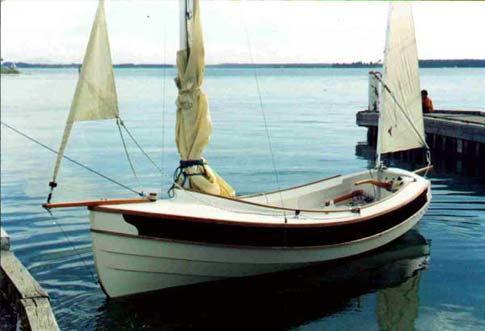

They feature hard chines and scow bows for lots of bouyancy when and where you need it. I love any boat with a bowsprit and these sport a nice-sized jib for light air to balance the sprit rigged mainsail. While looking like a bathtub on the hard, these are graceful swans on the water. We just joined the Center for Wooden Boats on Camano Island and they actually rent these beasts, so I’m going to head over there soon and literally get my feet wet.

The plans are reminiscent of the old Popular Mechanics style line drawings, but you could apply some modern stitch & glue techniques to possibly simplify the build. Also, being pretty much slab sided, I’m not sure how much a Maslow would help, but that’s why we’re all here. Once again, scarf/puzzle joints and possibly tiling your cuts rear their ugly heads, but that’s part of the design challenge fun. I believe these boats are also built on a frame/strongback so you have to cut the boat free once you’re done, rendering the frame pretty much useless if you want to build a second one.

An option that a lot of builders go for is putting a cabin top on their Pelican for dry storage and possibly a drier sleeping arrangement. With or without the cabin, these boats are serious camp-cruisers. This boat is definitely on my short list of potential future builds. I’m also a member of the Yahoo Group, which is a great source for info & support.

Inspired by @Sonny_Lacey build thread here, I thought I’d showcase a few more catboats. While you can order a magnificent Beetle Cat, the round hulls do not lend themselves to plywood/stitch & glue construction unless you develop several planks (scroll up to see the Peapod above).

Over the years, I’ve found several catboats that could definitely be built with the help of a Maslow. While some purists have had stability and handling issues with the various Stevenson Projects designs, I think the Pocket Cruiser might be a bit more forgiving. Knowing their approach, this is probably one of the more simple builds available.

I believe Sonny built his Bolger/Payson project based on the plans and the book (available on Amazon or Payson’s website)

Also, you can’t really discuss stitch & glue catboats without mentioning Sam Devlin’s Wompus Cat. He’s a great designer and I believe modified a Ted Brewer design for S&G construction. I’m lucky enough to live in the PNW, where I attend the Port Townsend Wooden Boat Festival in September every year. Sam is also local, so I’ve been fortunate enough to both see a bunch of his designs in real life and actually get to meet/chat with him.

So now that I’ve made the introductions, let’s discuss what catboats are all about. BTW, there are probably other designs out there that I’m just not aware of. Anyway, catboats are known for having a few distinct advantages. First, they are really beamy (wide) for their length. This does a couple of things. It means you can have a nice roomy cockpit for crew. It also means a ton of reserve buoyancy (the more it heels/tips, the more it resists).

The second advantage of being a catboat is they tend to be very simply rigged. They often have unstayed masts and only a single (albeit rather large) mainsail. This means they’re much more simple to sail, especially if you have a bunch of people in the cockpit. With that being said, there are plenty of catboats out there that the designers/builders have opted for a bowsprit for a jib to help with tacking.

Catboats are great, elegant daysailers (makes me want to wear that white captain’s hat). You could easily be the prettiest boat on the water every day you take her out (don’t forget the pennant on the top of the yard and to paint the top of the mast white).

If I lived on a lake, I would definitely build a small catboat to keep in the slip out back. I guess you could probably figure out a way to make one for camp-cruising, especially since a lot of them have a cabin option.

If anyone is looking for other plans for sail boats or other fun projects, I recommend looking at Stevenson Projects. I have already purchased all their pedal vehicles and am working on the 3-way truck now. I modified the plans quite a bit that they sent, but overall design is same. Most of my changes were on the mechanical parts (drive pedals, etc).

(Welsford’s Pathfinder)

(Welsford’s Pathfinder)

Okay, so let’s look at some more advanced/classic designs. While a Maslow might not be able to cut out all the parts for this genre of boats, it can certainly be a great way to start, as you can see below (Vivier’s Ilur kit by Jordan’s Boats). This totally looks like something a Maslow could crank out.

As I mentioned previously here or on Sonny’s thread, you can even use a Maslow to cut forms for steam bent/bent lamination parts. For example, the stem of many boats is bent around a form while the glue cures. Even cedar strip canoes are built this way, so the applications are endless.

Some boats that I find extremely interesting from a classic boat building meets modern materials/techniques perspective are the aforementioned Pathfinder and her little sister the Navigator by John Welsford (designer of the SCAMP). Plans are available in the States via Duckworks Boat Supply. There are several great build blogs of these boats with a quick Google search.

(Welsford’s Navigator)Speaking of Francoise Vivier & his Ilur, this is another classic small sailboat that is actually a lot of boat packed into a small package. Designed for heavy seas, she’s got everything you need for pretty serious adventures. Chase Small Craft offers a CNC kit that is very popular and there are also several great build blogs out there.

(Vivier’s Ilur) (another Ilur)The last of the top 3 entries in this category for me is Ian Oughtred’s Caledonia Yawl. It’s literally a remaster of a classic design that has proved its seaworthiness over the last couple hundred years. The yawl sail plan is very flexible and can be very effective in both light and heavy air.

(Oughtred’s Caledonia Yawl)These boats are all doable by garage builders. Yes, the build times for these boats are in the several hundreds of hours (I’m already over 200 hours on my Passagemaker build) and will probably take a couple of years to build, but in the end, you have an indescribably beautiful boat that is also extremely functional by some of our generation’s best designers. While I certainly can’t recommend these for first-time boat builders (unless you’re already an accomplished woodworker), you could certainly tackle one of these after having successfully built one of the more standard stitch & glue designs.

PT Eleven (not available as plans)

This will probably be my last entry on this topic of this type. I’m starting to run out of ideas, but here goes. There are many sailing YouTube channels out there and on a couple they’re talking about nesting dinghies. The ability to disassemble your dinghy into two parts is very convenient if you have limited space with your vehicle or on the foredeck of your sailboat. However, there are a bunch of trade-offs to be able to break your boat down into two parts that fit together. That completely dictates about half of the design. When you add built-in flotation, it gets even more narrow.

One channel built a Chameleon dinghy in a series of videos online over the course of almost 300 hours.

Chameleon Dinghy Build Summary Video

CLC’s Eastport Pram

CLC’s Eastport Pram

Chesapeake Light Craft offers a few dinghies that although they come apart, they don’t necessarily strictly nest. The Passagemaker and Eastport prams (discussed above in this thread) have take-apart options.

Spindrift Dinghy

The Spindrift is an interesting design that is available as plans, which can be converted to cut files. It has some design features that make it look similar to the PT Eleven dinghy, which is highly praised (but only available as a kit).

The common thread among nesting/take apart dinghies is that at some point during the boat build, you have to cut the boat in half. This is so the boat has nice, fair lines at the joint. If you built the boat in two halves, you’d have an ugly kink at the joint. This boat builder gave serious thought to the take apart option, but in the end opted out, partially due to the design differences necessary to make it a take-apart, but also partially due to the anxiety the cutting step would induce. I’ll see if I regret that decision while I’m wrestling with a one piece 12’ long dinghy that weighs 100 pounds.

Passagemaker Take-Apart (not true nesting)

If it is, i really love reading these. It certainly put building a boat at some point in my life on the bucket list. I never realised it is so doable.

You shocked me hard for a second with the first picture. I was relieved when I did not see the second part of the legs in the front of the boat and knew it was not a swordfish accident.

What made my sad was the ‘last entry’ thing. You are one of the inspiring group that was able to keep a dream alive. Once (if ever) budget kicks in I will attempt to build a boat. Will miss you.

If I can think of any other sub topics or you guys post something or ask a question, I’m more than happy to write something up. Also, if I ever convert paper plans to digital, I’ll document it. I’m just finishing my boat build, so I will also post some pics (even though it isn’t Maslovian).

If these posts have inspired someone, then they were definitely worth the effort. Sailing a boat you built is incredibly gratifying. The day you realize you’ve spent more time sailing it than building it is also a very special benchmark.

BTW, I’m running down to Seattle to check out the Center for Wooden Boats school. There’s a bunch of folks building the same boat that I just finished and we may talk a bit about rigging.

I’m a minimalist sailor. I bought my ideal boat a few years ago, a used Snark Sunflower or under $500. Small enough I can hoist it onto my roof rack, take it down to one of the local small lakes, and be sailing in about 15 minutes. I have absolutely no interest in building my own and no time to boot. But I have loved admiring all the lovely projects. Thanks for the effort you put into it.