The bracket that holds the z-axis and attaches to the sled… is that metal or printed part ?

wow awesome! i think you are the first to actually make your own z axis. Massiecnc, that is a piece of open builds C base aluminum extrusion.

ChrisB you can change the ratio of your z motor buy using a top plate with rubber belt like this contraption shows

https://www.aliexpress.com/item/CNC-machine-parts-NEMA17-23-stepper-motor-Z-axis-move-router-kit-2060-v-slot-Actuator/32866448394.html?spm=2114.search0104.3.180.54427da27NeNwC&ws_ab_test=searchweb0_0,searchweb201602_3_10152_10151_10065_10344_10130_10068_10324_10547_10342_10325_10546_10343_10340_10548_10341_315_10545_10696_10084_531_10083_10618_10307_10059_100031_10103_10624_10623_10622_10621_10620,searchweb201603_35,ppcSwitch_2&algo_expid=0f78157f-4b6f-4b3e-8bbc-b091665368f8-27&algo_pvid=0f78157f-4b6f-4b3e-8bbc-b091665368f8&transAbTest=ae803_1&priceBeautifyAB=0

That bracket I welded together with some 1/8" plate steel I had lying around, it is probably overkill, however, I am not sure I would trust a print for that. I had also looked at some angled brackets such as this. But as I continue to look something more like this shelf bracket might also work well.

If you are wanting to do a belt drive like that I believe that @MeticulousMaynard has done something similar with his Z Axis. He also uses that kit that you linked I believe and then builds a frame around it.

I went with my own concoction of an openbuilds C Beam with V groove bearings and then I got a gantry plate from amazon mainly because I thought I could do it cheaper than the pre built one on openbuilds. However, I realized that I still needed their lead screw and then I also had to make a shim to mount it to the gantry plate that I had purchased. Finally, by not getting the open builds one I realized that theirs is inset slightly so that you don’t have the problem that I do where screws get in the way of the bracket and I had to make a dimple in my 3d print so that it would fit.

That being said, if I were to do it again I would probably just pony up the first time and get their bundle and then modify it to my given router.

Hope this helps.

Good find! That might just fit the bill. And the price is about right too.

CHRISB - do you have any photos you can post of the frame back or without the 4x8 spoil board on it?

Here are some pictures of the back and cable management etc. I had to do some new brackets on my router because I did a stupid with a very large bit and found their breaking point. The pictures can also show how I used insert nuts on almost everything (including spoil board, motor mounts, etc). I also put this on casters that are double locking so that I can move it anywhere in the shop etc. I did totally overkill this, its 1.5" square tube that is 1/8" thick. I am not 100% pleased with the motor mount arms and they are kinda boogered because I was just needing the project done, I will probably go back and reweld everything eventually.

Back of Frame. I did a single support in the middle then used 1" tubing I had lying around for my corner bracing. (don’t hate on the arduino setup, I have a 3d cover for it but have been too lazy to install.)

Angles and Casters

My motor brackets and chain management. I have some ideas for the chain management but this has been working really well so I am sticking with it for awhile.

Sled update with my welded mounting bracket of the gantry to sled.

This just shows my general love of insert nuts.

Hope this is helpful!

CHRISB - Thanks for posting. I have some spare square tube so thought I may try to take a stab at one like yours. Does it seem to be tipsy at all?

It is a little top heavy but once I put the spoil board on it lowered the center of gravity a little. In my shop I don’t notice it being tipey but when I roll it around I do try to be careful. I may add weight in the bottom. If I did it again I wouldn’t use 1/8” wall, total over kill, I would probably go much smaller like 14 gauge or so.

nice to see a metal frame. If it was made out of 1/8" aluminum that thickness would be fine. But for steel 1/16 would be fine IMHO.

I would have loved to do aluminum. Unfortunately, where I live its much more expensive and I didn’t want to make this project my learning project for TIG Aluminum haha. I plan to pick it up in my copious free time (that I do not have).

lot of people have completed maslows, look in the community garden to see

examples of what they are building

several people have done CNC type Z axis, the key difference is that you need to

use a motor/encoder, not a stepper to drive them, so they need to be adapted.

you need a motor that draws <2A at full load, and then figure the speed of the

motor to work with the lead screw that you pick to give you reasonable speeds

Edit: Please watch volume on the videos, the router is pretty dang loud. Sorry.

After a long break due to other circumstances I am finally able to concentrate (briefly) on the dust collection for this Z axis setup. It is probably the single most annoying part of this design for me. I was able to make some significant progress on this over the last month. However, it is still a work in progress.

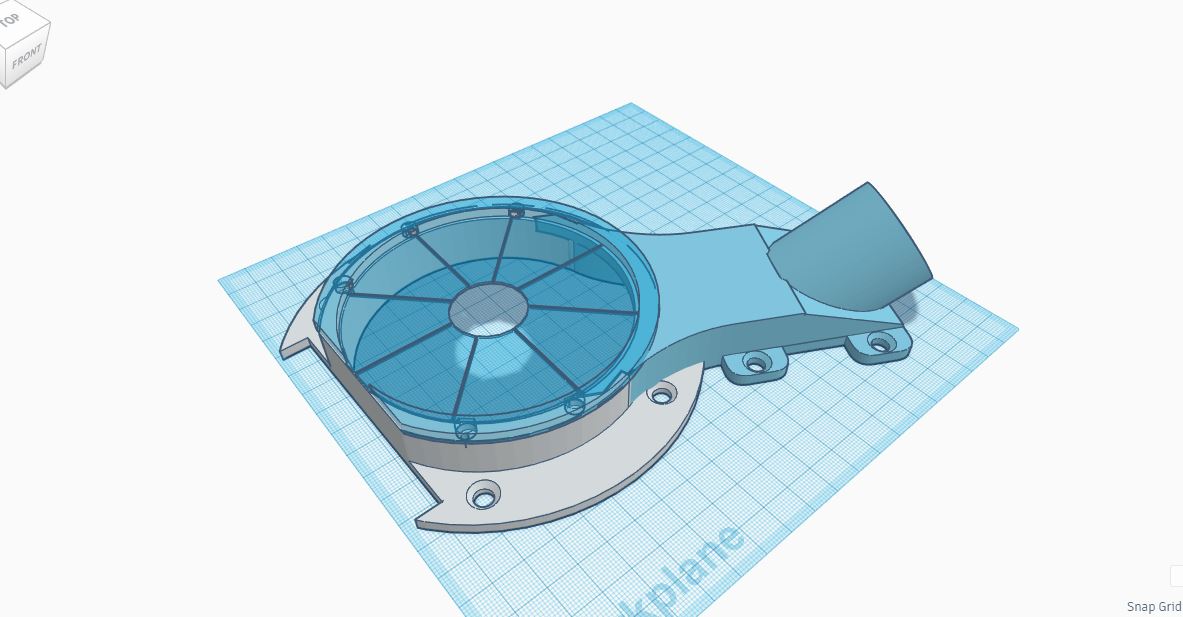

As I was looking for inspiration on this forum for what others had done I naturally came across the @MeticulousMaynard Z axis. I loved his idea for dust collection, however, for my setup this would not work because my C beam is right where the dust chute is on his design. With this idea I started to ponder how I could make this work for me, originally I tried to just rotate it and see if that would fit, but his base was much larger. With much tinkering (yes I did all of this on tinkercad  ) I merged it with what I had already started months ago for a design with a built in chute. This was the first design.

) I merged it with what I had already started months ago for a design with a built in chute. This was the first design.

I liked this design, it incorporated both Meticulous but also made an edit so that I could fit it next to by C Beam. I tried running my maslow in a square just to see how it worked and as you can see here. It did not perform how I was hoping.

This sent me back to the drawing board. I saw that Meticulous had a top piece but I wanted to have something more like the feather style of traditional gantry CNCs. Lets just say that was a horrible experience and I got a lot of superglue all over myself. Sorry not pictures.

My next design I made a shroud for the center area which was also 3d printed but it was triangular shapes that were only .5mm thick. This would allow them to have flex if the router ever does travel that low, but at the same time it gives something for the chips to bounce off of. This worked much better.

After that I realized that I wanted to make the chute a little larger and so I went back to the drawing board.

I found a hose that I would like to use since it has a good amount of flexibility and will work well with my smaller cyclone. I edited the chute to be wider and to also connect directly to this rockler hose.I then went further and added magnets so that the top area could be taken on and off relatively simply just by raising the Z axis and then popping off that top shroud. As you can see here.

I have almost completely installed this design onto my Maslow (sorry a 2 week old baby is slowing me down) but hopefully soon I will have my next revision (I think I am going to adjust the sides to make them thicker so that the magnets do not stick out. Maybe just make it look a little cleaner. I also plan on taking a dremel tool or belt sander to my sled so that I can taper the actual sled up from the router bit out the dust chute. Not sure if it will really improve the collection but I figure it can’t hurt.

But here are all of the STL Files for the 3 parts.

Dust Collection Base.stl (285.6 KB)

Dust Collection Chute.stl (256.6 KB)

Dust Collection Shroud.stl (103.4 KB)

@X7JAY7X I hope this answers some questions. I will try and get final updates sometime this week and maybe even make a video of it in progress. I am currently printing some adapters for the hose to my cyclone. I just purchased a shop vac so I am no longer stealing the wife’s shark vacuum for my dust collection  although it does work much better than I had thought haha.

although it does work much better than I had thought haha.

Glad to see that my design is helping with your Z-Axis setup. I actually quite like how you’ve run the collection chute, to avoid your C-beam. I did a lot of work myself to make sure that the chute would nest right under my rails and lead screw, but I like how you worked around the problem here. Keep up the good work!

I will need to do some more testing on my own design, but I do run into issues with the plexiglass window I may also make mine from triangles, like you have.