So a couple months ago I decided to lead a camp at SOAK the Oregon Regional Burn. I had a maslow for a while but I didn’t really have great time with 4.0. After I got my 4.1 kit I decided it was time to build a big project!

The idea is to create some trees with LEDs inside controlled by a microcontroller. The trees would be supported by a conduit shade structure in the middle.

There would be a box in the middle which would slot into a disk with some holes for the LEDs to go through.

Initial outside design

Once the box and disks were glued together I cut out the outside using a custom kerf bending design. The initial design looked a lot like wood but the pattern was very complex and it created a lot of small chunks of wood that clogged the vacuum.

This kills the maslow. I’ll talk about this later. It also took over 3 hours to cut one part. We were aiming to build 27 segments and we had a tight deadline of 2 weeks. So we simplified the design to be cut with a single engrave pass with a 1/4 in bit.

We then sanded everything and glued parchment paper diffuser on the inside. Then rolled the outside pattern around the disks and brad nailed it to the disk.

With a ton of help from my campmates we built 17 of these which was plenty for our stage because of a math error I did in the initial estimation. We were basically running the Maslow non-stop for about 2 weeks. We encountered a lot of issues and we must have taken the Maslow apart about 15 times during this period! I am also glad I bought a whole new 4.1 version so I could swap parts.

First Light!

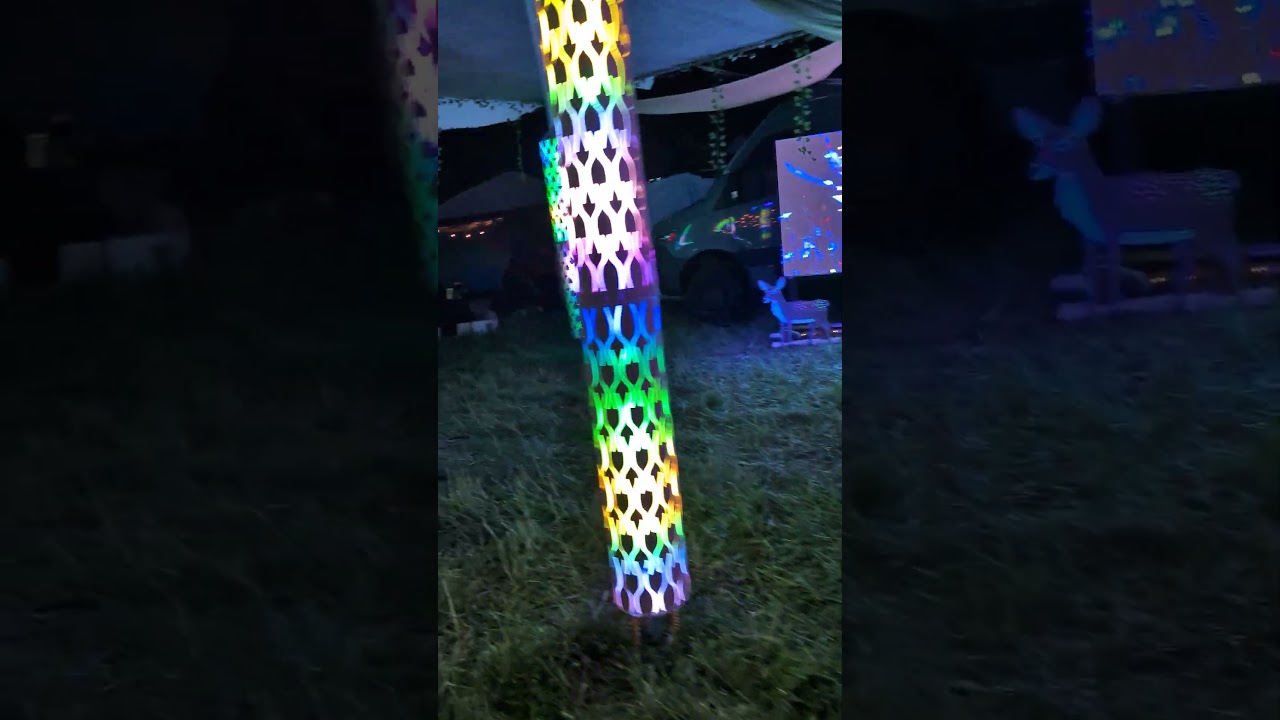

Video of the finished stage

Some ideas/tips I had a long the way.

I wish there was a bit more extensive self test during startup. Most of the issues I had were the belts going slack after cutting for a while. It would be nice if it could move around and test the belt tension to verify the calibration is good.

I would love to have a start job on line function. Maybe this exists but I could not find it.

The button pusher from the not store is a life saver! Basically required for any tool change. I also should have gotten one of those remove before flight tags. I left that in a few times and made the router unhappy.

It’s very easy to over tighten the bolts in the circle part of the arm causing increased friction. I must have missed this in the build instructions but this caused us a lot of issues early on. Also greasing the large gear that holds the belt was pretty much required on all of the arms we had. I would love to see these added to a troubleshooting guide.

The best way I have found to take it apart is to lower the z on M4 until you can get a allen wrench into the ‘Support Riser Top’. Undo all the screws on the top and then send the z all the way up until it comes loose. It saved us a lot of time and it’s way easier to access these screws.

Dust is a killer. There was a couple time where our dust extractor failed. I am pretty sure this dust got into the z motors and then they stopped going up. Then the router pretty much bottomed out and carved a nice pattern in my concrete floor. hehehe. To combat this I noticed dust would be pushed out when the motors went up. So I increased the z clearance while traveling to 12mm hoping this would flush them out. I noticed a bit of an improvement but I am not sure how conclusive the results are.

I want to design a 3d printed part to cover / clean the screws before they push stuff into the stepper motors. I also noticed after they got dirty they would get very hot. So I also slapped some heat syncs on them.

I would also love to get a z encoder to stop the thing before it bottoms out. I am not totally sure how you would design one that could deal with all the dust though.

The persistent problem we had was the belts going slack after a few cuts. I think it would take about 9 hours of cutting or so. After that we would have to recalibrate to keep the belts taught.

One thing I have been thinking about is that my spoil board is 3/4 particle board. It was mostly flat but it does curl up a bit on one end. I didn’t think it would be a problem since it flattens out when the maslow moves to that area and pushes it to the floor.

Oh also none of my circles were round ![]() it didn’t affect my project but I am going to have to do some measurements to figure out the right correction factor.

it didn’t affect my project but I am going to have to do some measurements to figure out the right correction factor.

Well this is getting long… Bar if you read this I would love to get coffee with you can chat, I am Seattle based. I would love to contribute some of these ideas to a troubleshooting guide but I am not sure where to start.