Nice project. Interesting work.

I am trying to build the triangulation linkage kit myself this week.

Wanting to lasercut the pieces of wood, I am wondering if the files for a lasercutter are available anywhere?

The linkage kit I am talking about, is this one:

http://maslowcommunitygarden.org/Maslow-triangulation-linkage-kit.html

yes the files are available.

in the swap meet topic, there is a pinned topic for the different kits, in the

thread for that triangulation kit there are links to the files.

David Lang

Just to clear up any misconception: in my kit the bolts can (should) be tightened completely (as tight as you want) and it will not affect the friction in the joints at all. This is because the friction point at the sled is the nylon bushing to the wood, not the screw to the wood. And the bolts clamp onto the nylon bushing and don’t actually touch the wood.

The nylon bushing is also the reason the fear of threads against wood is not founded (in this case). At the other four joints I use smooth shanked barrel bolts that also do not put any clamping force on the joint. They also can be tightened fully with no fear of extra friction. For these joints the friction point is the smooth shanked barrel to wood, again no threads in the way.

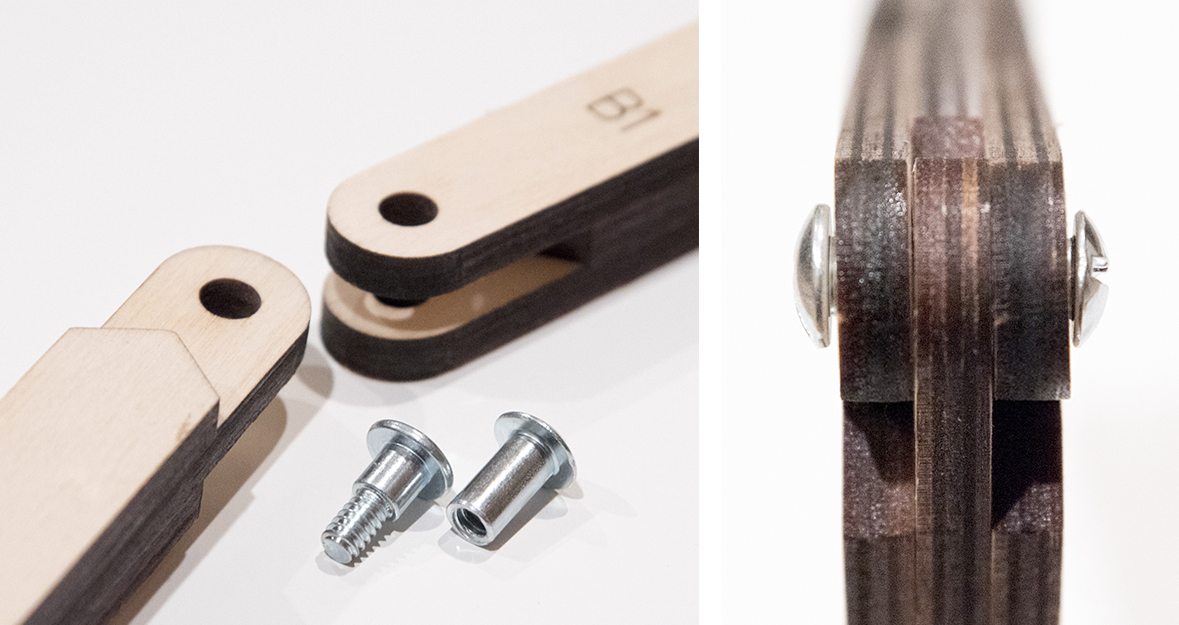

This is what the joints look like:

Notice that there is actually a little space between the bolt heads and the wood.

I agree with @dlang, I don’t think bearings will help much. This post explains why I feel this way.