This sort of worked, but I don’t have time to work on it more right now and might be useful given we are looking at motor currents / belt tensions etc (like @ian_ab 's Demonstration of 1x2 metre rectangle displaying motor current readings thread).

I bought one of those £5 luggage weighers:

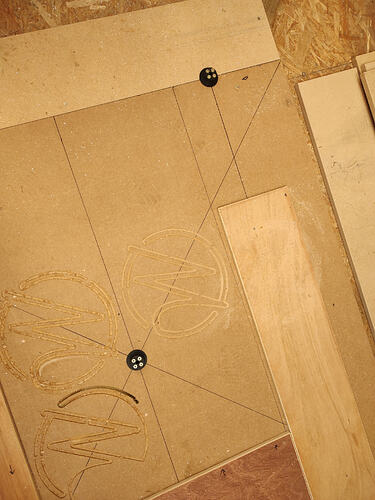

And modelled an ‘immobiliser’ to hold the sled in place (you sit the Maslow on it and it is modelled to fill the hold the router bit goes through in the centre):

https://github.com/DaveCoulthurst/Maslow4_hardware/tree/main/Maslow_4x4_projects/bits_and_bobs

Well, as you can see I printed a few and actually I bought 4 scales:

One scale for each corner.

My idea was to use Extend all / Retract all / release tension commands along with some tactical reboots to fudge my way to getting the actual tension in kg at 900, for the maslow centred, and in one corner of the cutting area.

I used the immobiliser to get the belt lengths, then did release tension, removed the immobiliser, re-set up and did retract all and took the measurements.

And it kind of worked, but i’m not sure how much I trust the results.

With it centred, each corner reported 12kg ± about 1kg (with 900 retraction force).

With it at the corner, the 3 shorter / close ones were 7-9kg, and the long one 4-5kg.

I repeated a couple of times, but I kind of don’t trust it because:

- I’m still on 1.07 (I’ll update when I have time, but I was happy while dialling in the actual cutting) - and 1.07 doesn’t show actual currents so I don’t actually know what retract all was doing / if it was hitting 900.

- The scales lock in a force that’s steady - they’re cheap, and that’s what’s needed. So i’m not 100% sure what I actually measured.

- Really I need strain gauges and the ability to force the Maslow to definitely stay at a set current while I measure each properly.

My plan was to upgrade to 1.15, and re-do, and separately to use the immobiliser (and a clamp maybe?) to see if I could measure for each arm separately the tension at 3/4/5 different belt lengths to see what I get.

No idea if it’s useful to anyone, but the immobiliser is linked if anyone wants to print their own and play with the idea - i’ve not had time to in the last few weeks, and not sure when I will.