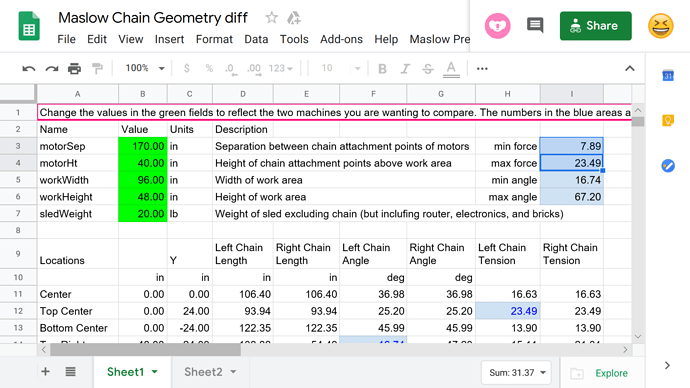

there is this spreadsheet that lets you try various dimensions, it doesn’t account for the frame angle (changes would be welcome)

the force available to the motors is always higher than the force of gravity, unless the force to move exceeds the force available from the motors (depends on real-world variables that you don’t know).

so you have two limits

-

the top center where the limit is how close the force needed comes to the force the motors can apply - friction

-

the bottom corner where the limit is the force of gravity to swing the sled, which matches the tension on the chain from the far corner - friction

The friction (both static and dynamic) is constant across the work area as long as the chains are parallel to the workpiece (and this ‘constant’ varies based on the surface it’s riding on, including the amount of tear-out from the current cut). Static friction matters because most CAM programs have the sled stop moving when you plunge into the workpiece.

All of the above varies by the frame angle, the closer to vertical, the better the numbers are (lower friction, more gravity available)

but the closer you get to vertical, the less force there is to let you drive the bit into the workpiece (but we don’t know how much force is needed, and that will vary on the bit and wood in use)

In the spreadsheet I don’t try to figure out the friction and plunge force needed, I just take the ‘make these numbers better than stock and your machine will perform better’ approach.

I believe that you come to similar conclusions, with pretty graphs, with a lot more effort, because you map out the entire space and the spreadsheet is just calculating the trouble spots.

There is an earlier tool ( http://lang.hm/maslow/v-plotter.py ) that does a more primitive version of the full map, which helped identify the spots to test.

The real problem is the unknowns that are needed to tie any of these numbers to the real-world

-

how much friction is there?

Of the (3.2 pounds-force modified by frame angle) available to move the sled into the bottom corner, how much is lost due to friction?

The closer to vertical you are, the less friction there will be.

If friction is 2 pounds of force, then going to a 12’ top beam which gives you 6.4 pounds of force takes you from 1.2 pounds net to 4.4 pounds net, even more dramatic than the doubled number looks.

-

how much force is needed to plunge into the workpiece?

As you approach vertical, the available force approaches zero.

without these two values, I don’t see how to modify either the spreadsheet you your mathlab work to do anything better than guidance as we can’t predict the actual results.

We could find the friction number by having someone with a high-speed camera measuring the acceleration of the sled from gravity (get a well-chewed workpiece, hold the sled with only one chain near the bottom corner, let go and measure it’s acceleration)

we can have people try tipping the machine forward while drilling holes and see how close to vertical they can get before the sled starts to rise (try with a fairly dull bit and hard wood)

we have quite a few people who haven’t had space in their workshop for a full 10’ top beam.

we have quite a few people who haven’t had space in their workshop for a full 10’ top beam.