Sharing a few pictures and info on my frame build. I got a lot of great advice on this forum, and found great examples. My end product will most resemble this.

I built it to store extra plywood and to be able to easily add skirting later.

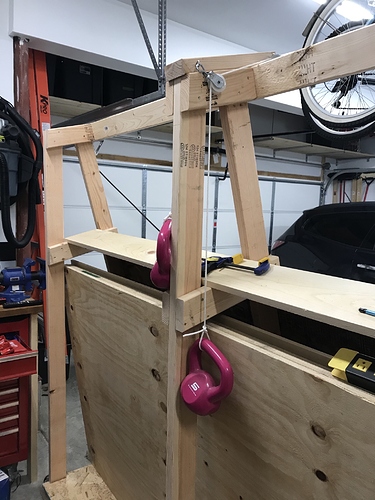

I started with building three triangular supports. Despite picking very straight kiln dried lumber and making careful cuts, they ended up being three different angles, and in the end I took them apart and reused the lumber.

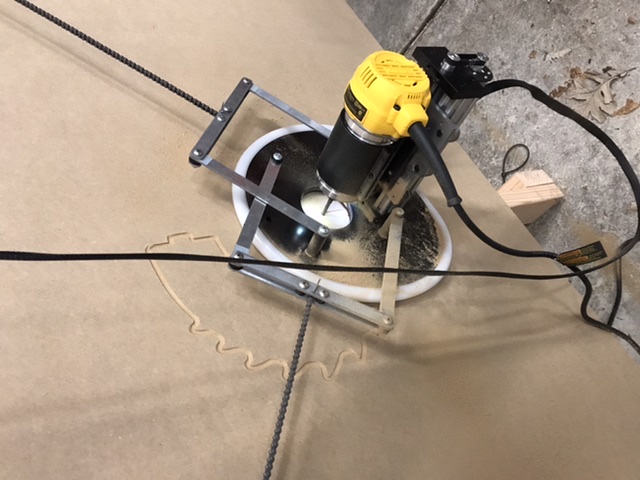

Next I decided to build my work surface plane on the floor, so keep it nice and straight.

I added a couple little supports to hold my plywood.

I temporarily supported it by clamping on some 2x4s and checking with a level.

Then I added my bottom supports.

Then the vertical back supports and another cross member to help keep it straight.

The frame is now taking shape. I will still need to add the top rail and some extensions to support it. I ordered a 12’ steel top rail from MetalMaslow, but it since it hasn’t come yet, I will wait to sort out how to do that later. It will probably be unistrut or 80/20.

I added some leveling feet and retractable casters.

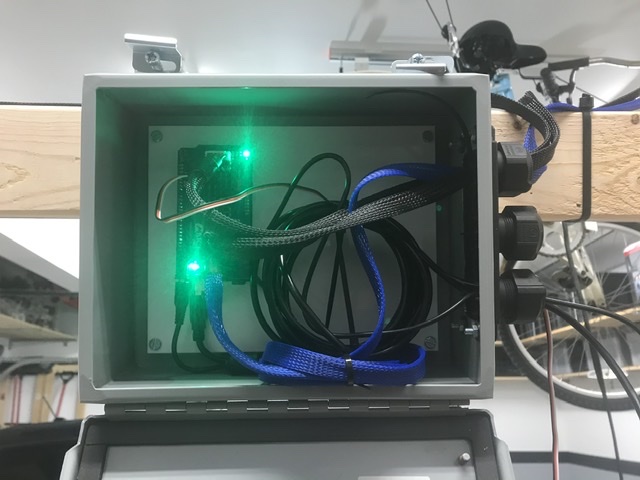

Then added a Hoffman box for the electronics bits.

Doing (one of) it’s important job of storing extra plywood.

I have a 2.5 car garage, which already contains 2 cars, a large workbench, lawnmower, snow blower, yard tools, etc. They all must stay. What’s left is a floorspace just big enough for the Maslow CNC, and a walkway to the side door.

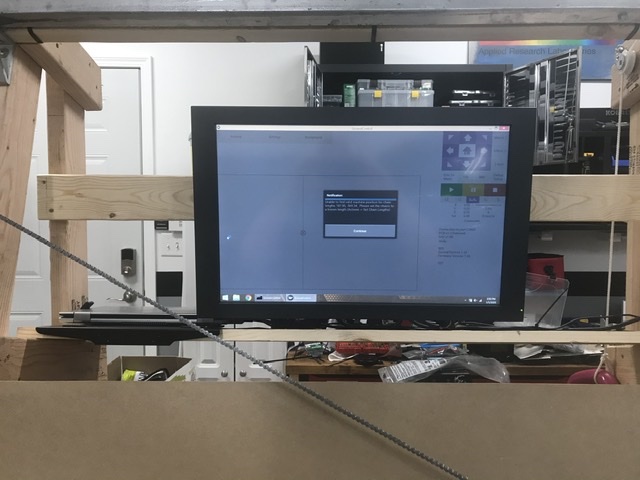

Next step will be to add the top bar, permanent OSB 4x8 sheet, assemble the motors and electronics.