This is what I did, nice thanks!

I can not emphasize how much this helped. 3 days of trying to figure out what was wrong…

Thank you so much !

I upgraded to the current latest interstitial firmware and index.html.gz. The calibration-complete is not popping early anymore, yay.

I did the multiple extend-all, retract-all-but-don’t-let-it-retract, extend-all-more and then retract all in an attempt to tighten the spools. Then I redid the calibration successfully.

But the spools are getting sloppy still pretty much immediately and I don’t know if that’s expected and/or ok.

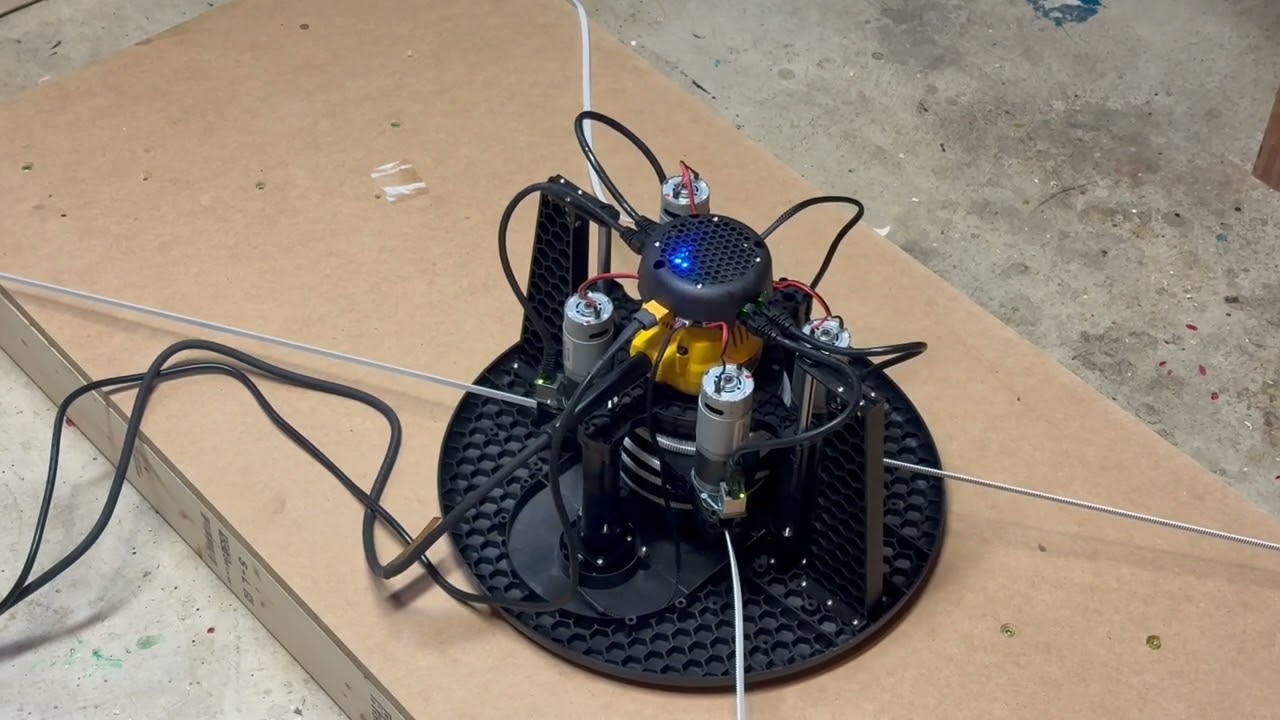

Here is the full video (2x speed) of calibration and immediate jogging around. Calibration is over at 8:10 and then I jog around a few times and you can see how quickly the spools get sloppy. Here is the log for the entire run (13.6 KB)

Can anyone please explain if this sloppiness is or isn’t normal/expected? Is the Maslow 4 going to cut just perfectly anyway? I’d be surprised if the belts aren’t always supposed to be held under tension even when moving away from an anchor to counter the forces from an engaged router bit.

I would try loading a test file and running it without a bit in the router and the router not running and observe if the belts stay tight as it runs through the simulated cut. I also found after the calibration, jogging the M4 the belts were not tight but after a power down and the retract/extend dance followed by Take Slack the M4 worked fine.

It’s not desired. The belts should always be tense.

Your frame looks too small for practical use to me, by which I really mean get your anchor points as far apart as possible. However, the bigger issue is that the sled is tipping off the edge of your waste board. The sled needs to be supported (i.e. kept level) wherever you need it to go.

You can always just redo calibration, and it will restart using the previous calibration’s values.

But sometimes that ends up being the ‘wrong’ starting point. So, you’ll need to re-enter the initial measurements you took into the config dialog and go from there. Note that the measurements aren’t actually the frame size, but rather they are the distances between the anchor points averaged out.

did you increast the retraction current limit? if so, you also need to increase

the calibration current limit (either through the advanced settings pulldown or

by editing the maslow.yaml file)

@bar, we really need to make it so that if you increase the limit in the

calibration start popup, it increases both values.

David Lang

I did not change that value. Why do you suspect that, please? Recommendation - In the “serial log” on startup, print out all the configurations, fitness scores, firmware version, etc. I see some of it, but I don’t think everything is there.

Thanks for that confirmation!

Hmm, I do want to hear more about this from you please. I wanted to start small and the FAQs said smaller was OK, but I’ve also seen that the community doesn’t have a ton of data yet to determine minimums and anchor margins (though folks ARE working on it ![]() ). I have smaller projects in mind at first rather than furniture - things that deserve mechanical precision, intricacy, and repeatability, but aren’t very big. These shapes will be well within the bounds plus my workpiece could overhang the waste board and provide anti-tip stability in a pinch. That’s what I’m thinking anyway - do you think I will really struggle with those things on this size frame & margins? Do you think it’s the cause of the belt sloppiness-on-jog condition that persists in my latest tests?

). I have smaller projects in mind at first rather than furniture - things that deserve mechanical precision, intricacy, and repeatability, but aren’t very big. These shapes will be well within the bounds plus my workpiece could overhang the waste board and provide anti-tip stability in a pinch. That’s what I’m thinking anyway - do you think I will really struggle with those things on this size frame & margins? Do you think it’s the cause of the belt sloppiness-on-jog condition that persists in my latest tests?

I’ve done the calibration five or six times now.

Surprising to me was that this last time, my early fitness scores were above 1.0 before settling down to 0.7405747 on the outer pass. These are higher scores than I’d seen previously (^^ above) and I would have guessed that fitness score range would be between 0 and 1.0.

I THINK the machine is done a pretty good job of navigating the work area based on the anchor measurements and work area that I gave it. As the video also shows, it gets around the board consistently with no issues now. Do you still see cause for concern?

the system pulls until it hits the current limit, at that point it assumes that

the belts are tight enough.

If there is too much mechanical friction (motor too close to the idler gear, arm

halves pinching the spool, etc) then it hits the limit while the belt is still

loose.

during operation, the limit is 4000, but the default for retraction and

calibration is 1300.

David Lang

I second the idea that the frame is really a bit too small or if not too small then small enough that you are pioneering something new so it somewhat uncharted territory. If you have the option to go bigger (for example by attaching directly to the concrete floor) then I think you will find that fixes a lot of your issues

well, wait - let’s get back to

If I get to the cutting stage and I’m seeing the M4 have difficulty holding-place along the y-axis due to shallow angles or something, that might hint at a physical limitation. But this seems to be handling motion OK - but just maybe some bugs in the software exaggerated by this extreme(?) case.

I don’t have alternative anchor points yet. I might like to scale up and had I known, I coulda built to some documented minimum, but these materials weren’t free so I’d like to please see this through - get a few successes before I invest more.

Sounds good! Lets figure it out. I just wanted to put that option out there if you wanted a quick fix.

How big is the calibration grid that you are running?

Cool. 7x7

What are the dimensions in mm?

1740mm x 1170mm anchors (as entered)

1100mm x 500mm work area.

Horizontal.

Can we try a smaller calibration work area like 800x400 and see how that impacts the results? I’m worried that the calibration process is taking too many data points close to the edge in this setup and that could be negatively impacting the results

Here is the post-calibration 800x500mm (sorry, I didn’t see “400”, but the fitness scores are good, right?). I again did a full extension (using @ian_ab’s technique), tight respooling retract-all, restart before 7x7 calibration.

Maslow-serial 800x500.log (13.2 KB)

that video is telling me that it thinks the two anchors for the belts that are

loose are further apart then they really are.

I would increase the calibration current limit and re-do the calibration.

David Lang

Visible in the earlier video - the belts seem reasonably tight during calibration, no? (again, I haven’t modified these values).

I may not have made it obvious enough that the latest video is POST calibration jogging. So it would be doing this during the phase where it has the default 4000 current limit (unchanged by me anyway).

I can try it, but I wanted to confirm all that with you first.

That is super weird. Just to verify, the z axis is all the way down during the calibration right? And you haven’t gone in and editted the frame size manually on the settings page post-calibration?

I am stumped, thankfully I am not someone that knows a whole lot about how this contraption works. ![]()