If you want to see how I got to where I am, here’s another thread about my calibration issues: Initial calibration on .70 firmware, horizontal frame. Failed?

After my last calibration and attempt to move, one of the belts was so tangled that I could not get it back on the spool, so I decided to just take all of the arms apart since I needed to check the fit between the motor gear and idler gear anyway. When I took the tangled spool apart I could see that at some point the belt had doubled over itself:

I’m not sure how/when that happened.

After getting everything back together last night, I upgraded to .71.1 this morning and tried again. When I did the retract/extend/apply tension, it said my coordinate system was accurate, but since I basically rebuilt the machine I decided to do another calibration. The calibration seemed to work fine, but once it was finished I immediately ran into problems trying to jog around the work area. I don’t know what’s wrong, but I will say it’s consistent, my results this morning match almost exactly the results I got on my last test a couple of days ago.

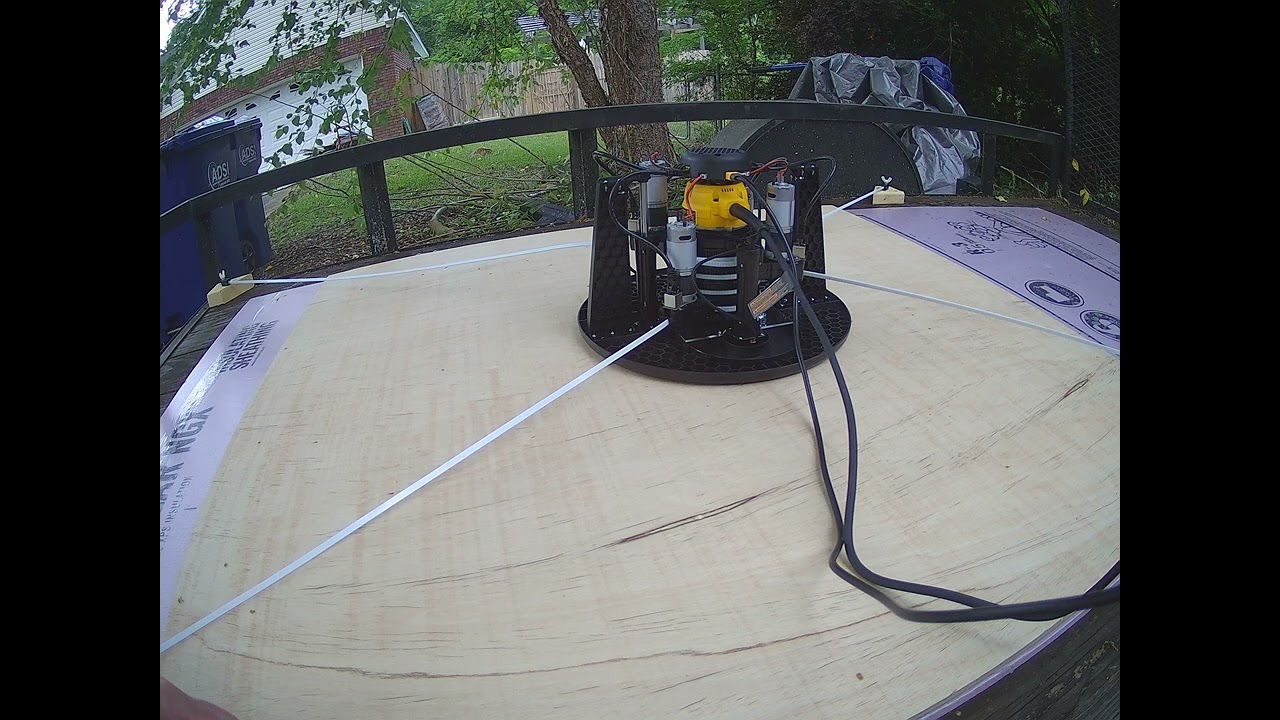

Here’s a video showing the last two measurement points followed by my attempts to jog around:

You can see it seems to move pretty well during the calibration moves. After the calibration, I tried to jog 100mm to the right. It moved to the right, but with a lot of slack on the left two belts. Sorry about the delay after the jog right, I was taking some still pictures. Next I jogged 50mm to the left, which seemed better, then another 50mm left seemed to put it back to home. I tried another 50mm to the left, and ended up with slack on the right two belts. I then hit Home, and it went down and to the right, leaving slack on all but the bottom left belt.

I’m attaching the serial messages from today’s test, along with the info from the FluidNC Controls page, including the Commands window in case that helps. Also my maslow.yaml file after this morning’s calibration. I started on Thursday with the version from the .70 firmware, set my rough frame dimensions to 1905mmx1420mm, and my calibration area to 800mmx400mm 9x9, then did a calibration on Thursday evening with .70 and another this morning with .71.

I really don’t know what to try next, any assistance will be greatly appreciated. Let me know if there’s any other information I can provide.

Thanks,

Russ

maslow.yaml (5.2 KB)

050424-Cal1-SerialMessages.txt (24.9 KB)

050424-Cal1-Commands.txt (11.2 KB)