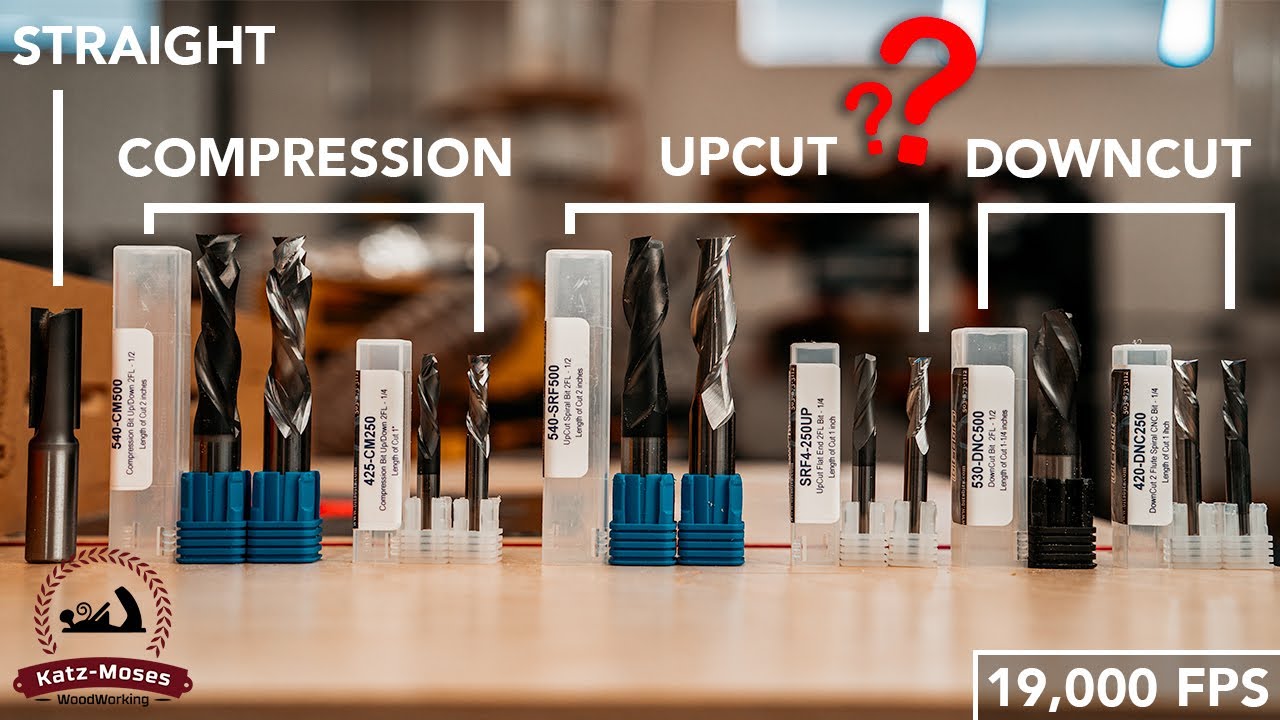

Jonathan Katz-Moses just did an excellent video examining straight and spiral bit types in slow motion.

However, I don’t know if we can use his advice for the Maslow…

Straight bits - Not recommended, causes a lot of chatter and rough edges and not good at plunge cutting. Sounds true for Maslow as well.

Downcut - Gives the best edge, but you need to do a ramped plunge in order to clear chips. From what I can tell, ramped plunge cuts aren’t really a thing with Maslow, since the Z axis is so slow. However, we (I) normally don’t do more than a 1/4 inch deep cut per pass, so chip clearance might not be a big issue with profile cuts.

Upcut - Best chip clearance, ragged edge. (I’ll admit that the slow motion cut looked terrible with a ragged edge during the cut, but there didn’t seem to be a lot of edge blowout after the bit had passed.) I use an upcut bit most of the time, and on sheathing grade plywood the edge can be pretty ugly.

Compression - Left the best edge for plywood, but you need to do a full depth cut - otherwise it functions just like an expensive upcut bit. I hadn’t thought about this, but it makes sense. If the upcut portion of your bit is 5/8" long, you need to have a cut depth greater than 5/8" for the compression bit to do its magic. (I did a 3/4 inch deep cut once on my machine and it was kinda terrifying before I could cancel the program. ) With our typical shallow cuts and multiple passes, a compression bit doesn’t seem useful on the Maslow.

So what do you all think?