It’s the same as this one

Here’s what I have in mind. The C-beam, gantry and lead screw assemblies are already on their way. The only things I need to fabricate are:

- top plate that the maslow Z motor mount to

- idler tension arm

The rest of the items are off the shelf.

Fusion 360 model here

I welcome your thoughts.

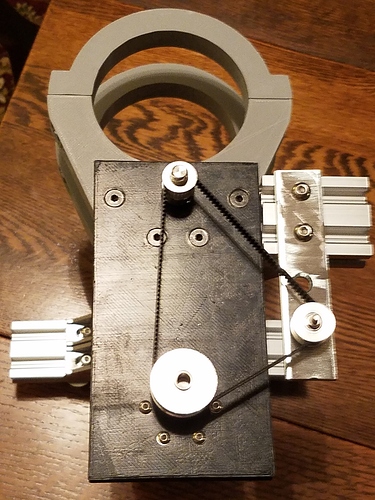

Here are the results of my new Z-axis build.

Hasn’t been tested on the machine yet, but quite happy with the build out, Need to double-check the calcs for the lead screw and pulley differences before hooking it up. I got several different sizes of pulley so I can run at different speeds. For instance I cut a bit of aluminum and needed to plunge a little slower. In 3/4 ply, can go a bit faster than stock. And for my dithering photographs project, very fast would be well worth it.

Parts come in just a little north of $100 but should be well worth it.

Much credit goes to Meticulous for his Z-axis. I took a cue from him for sure but drew it up to fit the C-beam gantry and designed the end plate to match the maslow motor.

Some explanation on the router mount. They are 3D printed in SOLID plastic (100% infill) which should be strong enough to hold the router securely, but to attach them to the gantry I put the two slots near the rear, in each, and dropped in a matching piece of metal that is tapped for the attaching bolt. The result seems to be quite strong. Time will tell.

Using Maynard’s calc sheet with a lead screw of 8mm/rev it looks like the 3 pulleys I bought (20T, 30T and 40T) yield the following possible Z speeds, by gearing both up and down. Plenty of options.

| G1 (motor) Teeth | G2 (lead) Teeth | Ratio | G1 RPM | G2 RPM | mm/min |

|---|---|---|---|---|---|

| 40 | 20 | 0.5 | 12.6 | 25.2 | 201.6 |

| 40 | 30 | 0.75 | 12.6 | 16.8 | 134.4 |

| 30 | 20 | 0.666666667 | 12.6 | 18.9 | 151.2 |

| 30 | 40 | 1.333333333 | 12.6 | 9.45 | 75.6 |

| 20 | 30 | 1.5 | 12.6 | 8.4 | 67.2 |

| 20 | 40 | 2 | 12.6 | 6.3 | 50.4 |

The picture is showing the 40T driving the 20T.

To be able to use the same pulleys on either the lead screw with an 8mm bore or the motor shaft with 6mm bore, the pulleys are (obviously) the larger 8mm-bore. Then I use an adapter sleeve over the motor shaft that has a hole drilled through its side to allow the set screw to pass through the sleeve and tighten against the motor shaft.

Welcome your comments.