Hello - Long time listener, first time caller. I’ve been a fan for years. Now, with the 4-point anchor system cutting flat on the ground, this finally feels possible to me. My tiny garage workshop can’t fit an upright frame, but… I have a driveway!

I have many “what if”, “how difficult is it”, and “how precise” style questions to ask, and I’ll gladly take anyone’s experience or input.

I have a long-ish, flat-ish driveway, which slopes down to the alley. I already build and sell equipment which I outsource the CNC work on. Currently I send it through a local company or cut it at the school where I work. In spite of all of that, I am thinking I would like to add 4 anchor points to my concrete alley for occasional light-production, prototyping, and one-off builds, either to save money, or save the time of my colleagues who might have better things to do than help with my non-school related projects.

SO - The first question is set-up time. If I had prepped files, a sheet of ply and a foam backer, and at least one or two bars of wifi signal, how quickly can I go from an empty driveway to annoying my neighbors on a Saturday morning with the sound of a router? Working outside means a full setup and teardown with every build, and being at the mercy of the weather. I like to pretend I have time to do big projects, but in reality I have a handful of small bits of time I can slowly work through ideas on. If this is a 1-hour setup and 30-minute teardown, I’m already out of time.

My next question has everything to do with accuracy. My builds aren’t overly elaborate, but they are somewhat technical. They involve some or many pieces which all align, fit together with dadoes or rabbets, and all with pretty tight tolerances in 18mm birch ply. Am I asking for trouble with my expensive ply and inexperience? Reading through the forums some, I’ve familiarized myself with Z-offsets and skewed belts, plywood moving, etc. These are all things I can account for. But if the center of my sheet cuts accurately, and the corners are skewed or trapezoidal, that’s a dealbreaker. I usually cut full 4x8 sheets, and pack my pieces in tight, so I need a good degree of precision. I am expecting to have bridges on all the pieces and still follow up with a fair amount of hand-work.

Next, Tool Changing. Ideally I’d like to drill a bevy of 1/8” pilot holes, and then follow up with a 1/4” bit to cut dadoes and profiles. Is this possible? Should I plan instead to give myself shallow 1/8” drill marks and follow up by hand later?

Finally (not true, I’ll have more questions later) - Can accuracy be increased by extending or changing the placement of the belt anchors? The Concrete Floor Guide recommends 8’x12’ corner anchors. Is there a benefit extending that or changing the 2:3 ratio?

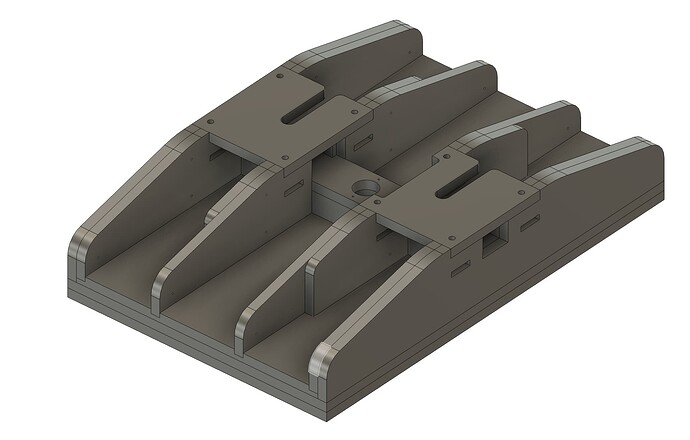

Below are 2 screenshots from Fusion, one of a full build of a flat press platen, and the other stripped down to just a few parts to show where the complications lie. This piece is 20x30” outer dimensions, and collectively it uses most or all of a 4x8’ sheet.

Apologies finally if this is in the wrong forum topic. I couldn’t decide on the right home for these questions.

Thanks all!