I like the look of the metal frame. I may copy parts of it. I am notoriously cheap though and I am a major pack rat, and I have a good tool collection so I may combine some of those attributes and make a few changes. I think I could pull the frame off for free or very near free with the following components.

Some good old dumpster diving or roadside scavenging…

You need a few metal bed frames that are made out of angle iron. Three old frames would give you the uprights and the bottom rail and even some braces, I use a grinder to take the rivets out that I don’t want and an inexpensive metal chop saw to cut them to length. If you are on the cheep you could get away with a grinder and an abrasive wheel and a cut off wheel. If you can work around the riviots you could get away with a hand hack saw and lots of elbow grease.

And for the top rail, I would find a couple metal futon frames. I am always looking for them anyway, I generally have uses to the ladder line sections. Take 4 of them, tie wrap them together and you have a nice baby critter pen so you can let the kid goats or little lambs have a piece of the lawn and nice fresh green grass etc…) I also want a couple for window guards in my wood shop as I am paranoid of my accidentally pushing a long board through a window. However in each of them there is also a strong piece of metal tubing that has a flat metal flange with two holes on each end. I think two of them bolted together would be the top rail.

And with the remaining small pieces of angle iron, I would drill and tap holes an inch or so apart and than cut them into individual brackets with the metal chop saw. Much easier to drill and tap the pieces when you have a big piece to start with.

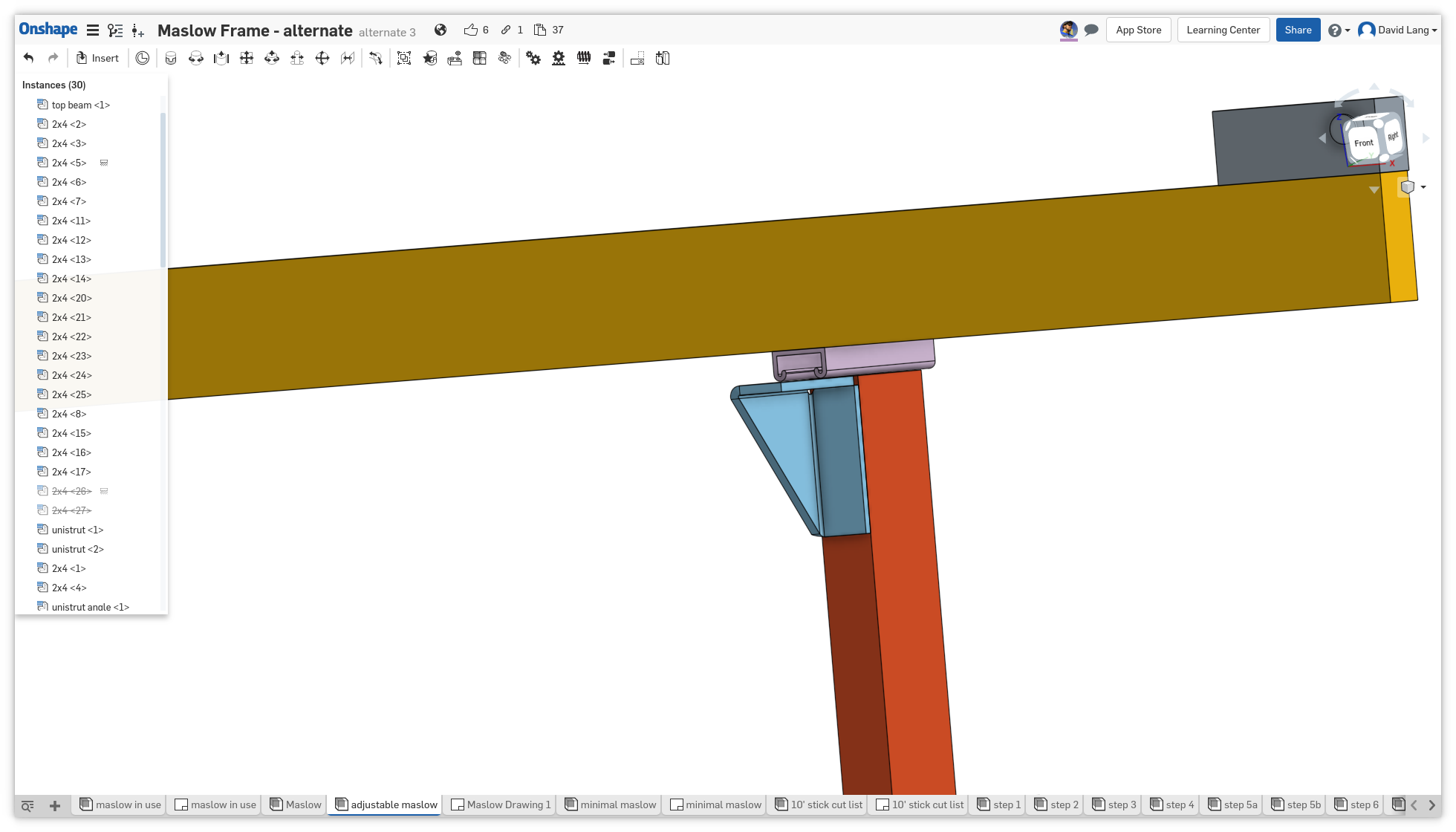

I was initially thinking that I could rig weld the Aish shaped sides, but thinking on the bed frames, they have that pivot joint in them so they can fold up. That might be the top of the A right there and either bolt or weld more angle to the short piece. That would also save having to grind out that riviot. The brace in the A’s could bolt on as would be the cross members.

For tools I am thinking the chop saw, an electric drill with a through hole bit for your hardware and a tap sized bit for your hardware, and a tap. And the chop saw could be a grinder or even a hack saw if you wanna work…

This is an interesting concept.

As an aside I have free reign over a lot of rough cut oak 2x4’s. I have built more stuff out of them than I can count, and I was going to build my frame out of them, but the hardware costs are high as you need really long bolts to go through them. I think in the end, the metal frame would be less expensive and the hardware costs would be much less.