Hi. I was wondering if there were any planned updates for WebControl? I am a retired user interface designer, and would not mind adding my expertise to the project in the form of a cold eyes review. I don’t have the coding skills to do the work, but three decades in the field brings plenty of good ideas. Anyway…just if there is need. JEH

I have been noodling on webcontrol to put in some additions I added on my Maslow, but they are most (but not all) raspberry pi specific. I could use another set of eyes to verify functionality and suggest changes to documentation if you want to look it over. My web coding skills are limited, but I can usually make stuff work. I think the documentation for calibration could use a revamp as well.

I’m still a novice and I’m quite impressed with webcontrol. So far I can’t really think of much improvement. I’ll throw some ideas into the mix, they may be stupid or not practical since I no nothing about coding. So here are my newbie inputs:

-

Is there a way to program in a better way to recover from a com loss?

-

Is there a way to add in gcodeclean as a function? I’m thinking load gcode, then go to gcodeclean menu and pick how you want it cleaned/modified. Or at least add in zclamp?

-

Maybe a few more macro buttons?

-

Maybe a button that cycles through tool change commands (even if maslow doesn’t recognize them maybe a manual cycle to add in router stops)?

-

A ruler tool.

I’m going to add on that I’m impressed with you guys keeping this project going!

-Tim

I’m still a novice and I’m quite impressed with webcontrol. So far I can’t really think of much improvement. I’ll throw some ideas into the mix, they may be stupid or not practical since I no nothing about coding. So here are my newbie inputs:

- Is there a way to program in a better way to recover from a com loss?

unfortunantly you have no way of knowing exactly what gcode lines have been

processed, and when the connection is lost and reestablished, the arduino is

reset. This makes cleanly recovering extremely difficult just from a conceptual

point of view (let alone practical)

Is there a way to add in gcodeclean as a function? I’m thinking load gcode, then go to gcodeclean menu and pick how you want it cleaned/modified. Or at least add in zclamp?

Maybe a few more macro buttons?

both good ideas

- Maybe a button that cycles through tool change commands (even if maslow doesn’t recognize them maybe a manual cycle to add in router stops)?

not sure what you mean by this.

- A ruler tool.

explain what you mean here please?

David Lang

I agree with @dlang’s comments

-

the only way I can think of to help with comm loss is to drill a hole at your home location before you start and then rehome and restart when you have comms again. Maybe have it save the home coordinates from the last job so they can be restored after a chain reset which is required after a power failure. Have a listing of jobs that have been done with home location and cut time as a historical record… hours of run time for PM or something like that.

-

gcode clean could be added. I can look at that, though that will likely be its own deal because there are many options for it.

-

where would you put the macro buttons? @hangtentex where would you put more macro buttons?

-

tool change commands… that is a firmware add. webcontrol could send the gcode, but if the firmware on the mega doesn’t know what to do with it, it won’t really help.

-

I tried to get webcontrol to tell me how big the bounding rectangle was around the cut on a text display so I could position appropriately for partially used sheets. A ruler might help in this regard, though the board function really helps here as well. Could you clarify what you mean by ruler?

I’d probably just place 3 more across the top right of the word “controls”

Click on the “ruler” button click on one point of the screen and then on the next point and it will tell you the distance between the 2 points.

I like the idea of the ruler. That won’t be an easy one for me, but I’ll look into it.

Here is something in webcontrol I was adding for the raspberry pi:

macro buttons up here? (text not showing correctly yet)

How about a search function when you open up gcode to edit so you can find the next “M” or “T” code then you can through in a pause and a stop router code to change bit. I think “T” codes are seen but ignored by maslow. Finding it via searching would allow you to enter a code to stop and change bits.

-Tim

Yeah I’d put them there but make them the same size as the others.

At least some versions of maslow firmeware will see T commands and if the tool

number is different from the last one, pause and wait for the user to change the

bit, zero the Z axis, and hit resume.

David Lang

Once I get the setting-stored label text to populate on the button face, they will be the correct size.

EDIT: like this →

works:

mobile:

That looks amazing!

And I added a z-axis PID tuner similar to the x-y PID tuner already in webcontrol:

i published a prerelease here if you want to test it out:

Newbie questions. Do I have to write down my settings before I download? Will I have to recalibrate? Thanks

-Tim

There are ‘sensible-ish’ defaults for everything. So all it really needs to know is just the input filename. The others are there for fine tuning certain operations:

- So output control with

--minimise,--zClampand--annotate - And tolerances for linear and arc deduplication with

--toleranceand--arcTolerance

The arduino board that I’ve got (MakerMade kit) has a limit of somewhere around 10 lines. So, if comms is lost then a ‘good guess’ can be made about which line was being processed when that occurred.

First of all though I have to agree about drilling a hole at home location as the very first thing done.

Next I think it would be great to have a ‘jog & shuttle’ approach to fast-forward (like video equipment that runs off tape) - So the tool is always kept up (+ve Z axis) - and then just jump forward x number of lines, to whatever the position would be, being able to dial in on x as you get closer. With a soft restart, playing through lines, up to where the failure occurred, to gradually drop in the bit and keep going.

No calibration required if installed in a folder next to the existing webcontrol install. There is a hidden .WebControl folder that has the webcontrol.json settings file in it that must be found by the program in order to find and maintain your settings. In linux and rpi it is in the user’s home folder so is easily found. I’m not sure where it is on Windows.

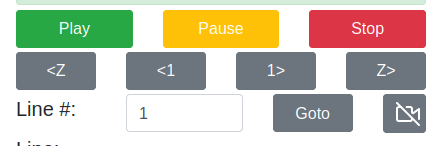

Webcontrol already has the go to line number, go to next line and go to next Z axis move with these buttons:

then just press play to resume from that line.

Yep - those I know - but sometimes you lose track of where you want things to resume from, being able to ‘dial it in’ literally by having the sled move to where it would be for a certain line would be very handy.

The other thing is that you might not know what the depth of cut is for a particular line. If resuming from a particular line is that replayed (because I don’t believe it is)?

So you want to step through the file and have it tell you what the location and depth will be at that line? Then you want it to be able to move there and then start processing from that point?

EDIT: I wonder if a z-move delay might be a good option… move the sled, but put the z axis at travel height, step through the gcode file line by line moving the sled, but not the z axis… then engage the z axis to the correct height before starting the cut from the current location after the z axis is in its proper place. That will require intercepting the z axis commands and removing them from being sent to the controller and keeping only the last one. Still thinking on how best to do that…