Oww my eyes! Got anything a tad slower? I’m interested in seeing how smooth the movement around the ring is. ![]()

Yes, I will film something not sped up

Now all you need to do is to incorporate a Z-Axis motor for the riser that is parallel’ed off the router Z-Axis motor so it moves the riser up and down proportionally with the router!

Thanks for that Bar and others.

As I noted I am also excited about the ring concept I just wanted some active dialog and pro’s and con’s before it was standard.

The $40 target is great as this is comparable with the linkage kits.

In terms of bigger routers I have started a thread called Sled Dimensions. I also noted what was the largest radius that could accomodate the linkage options without interference. For this we need a 2D drawing for each working router.

In the case of the Bosch GKF 1600CE the PVC base plate radius is 77mm. I am not sure what the radius of the base of the Ridgid Router is but if we had marked up dimensions then the answer would become clear.

There is also a lack of clarity around the riser height (this applies to both the linkage kits and the ring arrangement). As noted there are two things that need to be accounted for namely the Centre of gravity in the Z plan as well as having the linkages parallel to the workpiece.

I think we certainly need a 2D drawing outlining this for all options.

Kind Regards Stuart

Thanks for that David. I am planning on using layers of plywood for the risers as my first option to get my unit close.

Kind Regards Stuart

The riser height should only consider the center of gravity in the Z axis for

the sled.

To make the chains parallel to the workpiece should involve moving the motors in

and out (a problem for the current default design, pretty trivial for a

top-mount design)

David Lang

David,

Were you referring to the current Default design as relating to the frame construction?

Where does the current COG lie in the Z Plane?

Stuart

Were you referring to the current Default design as relating to the frame construction?

Yes, the frame design with the nice, pretty wings attached to a piece of

plywood.

This then puts the motors on smaller pieces of plywood sticking out from the

wings.

The result is a large distance from where the chain is and where the strength of

the wood is (in all dimensions).

Where does the current COG lie in the Z Plane?

with a ridgid router, somewhere around 3-4" up from the top of the sled.

Thanks for that David.

Stuart

I am definitely going to purchase the ring kit when it becomes available.

I was thinking of trying to make one out of plywood, easiest to make, but thought that it would probably not last too long.

Well done everyone, the new sled ring addition to the kit brings it so much closer to the gantry flat bed cnc’s

i dont know if it been said or not but theres at least 5 people that i would like to have this ring before i receive my maslow this feb. just for pure insight on the construction and what not to do or to due plus plenty more things that they c .so i will pay for 1 of the five to get it if this is pausiable

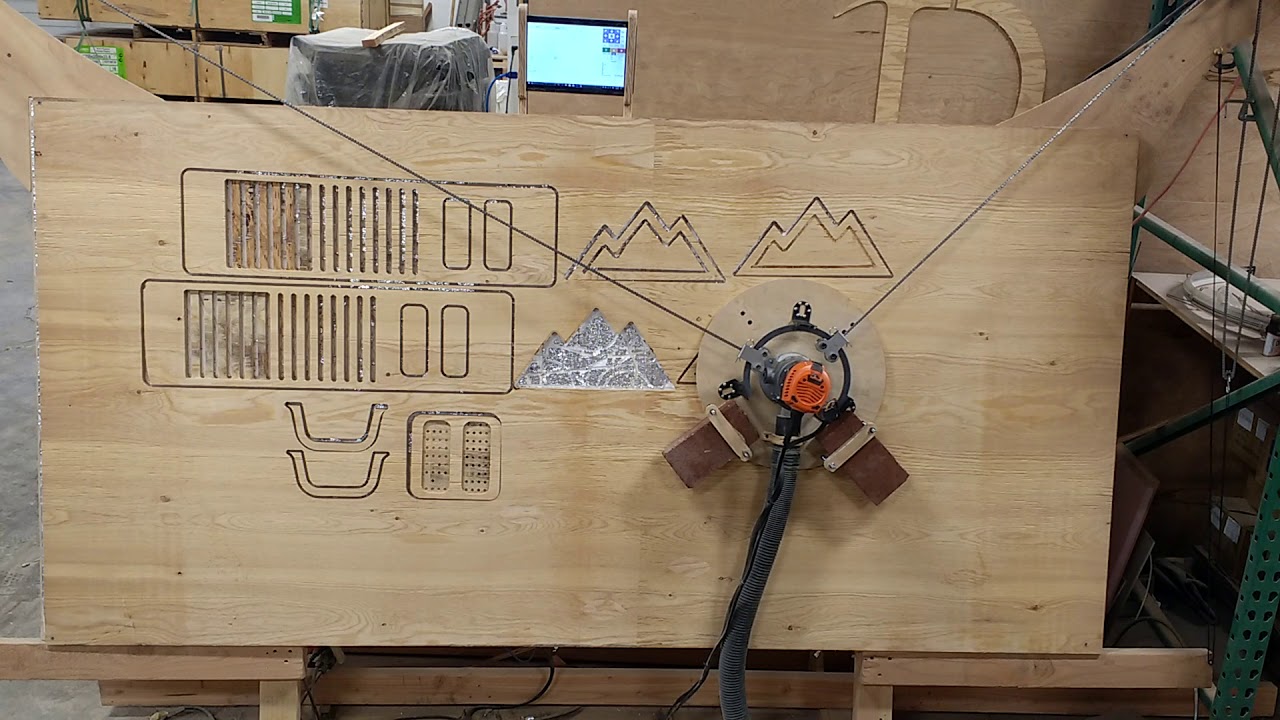

I think Bar’s ring is going to be great but in the meantime I made a ring out of 1/8" aluminum sheet using a trim router and piece of wood as a circle cutter. I used some bar stock to make the bearing chain arms.

I’ve seen mention of risers in the post above and @dlang you are chatting about using some blocking here. Have these options been documented somewhere “official” yet? I start my build this week and am honestly feeling like I’m drinking from the fire hose a bit on choosing my frame design and getting the most accurate setup. Sorry to be “cheeky” but it would be helpful to have some of these “must have tips and settings” outlined somewhere without having to read through and piece together forum threads.

Just struggling to know how to get the most outa this machine and leverage the amazing work of the community  to that end it would be helpful to have some of this consolidated. I’m happy to help do that if folks can point me in the right direction.

to that end it would be helpful to have some of this consolidated. I’m happy to help do that if folks can point me in the right direction.

Cheers,

Ben

the big threads all start off with simple posts, it’s the discussions that both

make progress and make it hard to track what’s what.

as for ‘official’, what does that word mean

does it mean ‘what Bar ships’, does it mean ‘known to work’, we support just

about anything

it would be really good to have someone make wiki pages for some of these

things. Even if you aren’t sure you understand them, getting anything together

on a wiki page can then be edited to fix anything that you miss.

I see a few categories to try and document

-

theoretical concerns

ridigity between motors

chains attached to sled at balance point

chains parallel to workpiece

chain skipping problems

width/height

weight/friction

chain sag/stretch

kinematics (how the machine moves)

quad kinematics (the traditional fixed brackets on the sled)

triangular kinematics -

implementation details

A) Frame design

i. motor/workpiece support

traditional ‘wing’ design

top bar design (wood or unistrut)

‘wall’ design

ii. structure

A frame

hinged to wall/cealing

folding

cart

B) Sled design

i. quad kinematics

ii. triangular kinematics

bearing

ring

45 linkage

top linkage

C) chain guides

I am able to quickly provide text for any of this stuff, but it takes me a LOT

longer to get around to doing any diagrams of this stuff.

A fair bit of the diagrams can probably be assembled from pictures posted, or

exported from CAD systems (at least to start with)

Totally agree on the “making progress and also making it hard to track”. Being in the software world I totally understand that about open source  the blessing and curse for sure.

the blessing and curse for sure.

I really like the idea of wiki pages and I’d have to say that would seem “official” enough for this guy  . I am pretty new to the community and having not built my machine yet I’d have to say that with all the new developments coming out recently it’s a bit hard to decide what to build specifically.

. I am pretty new to the community and having not built my machine yet I’d have to say that with all the new developments coming out recently it’s a bit hard to decide what to build specifically.

In any case I am more than happy to be part of the solution. If folks have specific posts or brain dumps I’d be happy to chip away at making wiki pages.

Just lemme know and thanks for being such an awesome group!

~Ben

musings on frame design covers a lot of the frame stuff

throwing my hat into the ring covers a lot of the different triangulation

options (there are separate topics for the two linkage kits, links from the swap

meet post)

there’s already a wiki page on accuracy, which goes into the differences between

the two types, but needs diagrams (especially of the quad kinematics)

Any updates on the arrival of the ring kits in the store?

Thanks for the reminder! We’ve got a little bit too much going on to have it up for the newsletter today, so It will probably be some time next week. We’ll make an announcement as soon as they are in the store here in the forums for those of you following along closely, and then mention them in the next newsletter also.

We did get one set shipped overnight so that I could test that all the parts fit (they do thank goodness) and we’ve added the pictures to the “What’s in the box” page here http://www.maslowcnc.com/whatsinthebox/ if you want a preview