Thats the kit I have been taking cues from! I won’t be re inventing the wheel here just a very similar design that will fit around my z axis

here are the bits I have drawn up the longer arms are 160mm hole to hole and the shorter ones are 100mm should fit my sled nicely

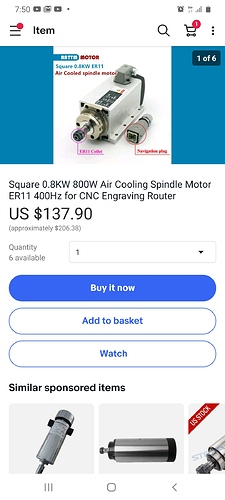

Which 800W would you recommend?

I haven’t tested any, not even tested the 500W on long run. (will soon)

So can’t give any recommendation. My budget is always low and i pay no tax from china, i’m forced look at Ali what they have and trust on luck. I do think that the one with the shiny metal body look more solid and are higher priced, so i assume they are better on the long run. The desktop-cnc forums should have some info that i would check before buying.

I did see these as well, integrated mounts which is nice

https://www.ebay.com/itm/373044367848

What are you going to cut with that monster??? 10mm titanium? (joking here)

I went within a few months from an over-weight, over powered (in relation to the feed-rates we have, 800 mm/min now {with acceleration/deceleration planing perhaps 1200 mm/min soon}), to a max-light-weight sled for a reason and added weight (flat) in steps to find the ‘sweet-spot’ to be able to increase feed rate with out to much mass ‘swinging’.

My monster 3 years ago, just because it was the only thing i could find on an tiny island between saudi arabia and iran to mount a z-axis.

That beast has 7 kg alone, not counting the bricks.

Not going back there

Edit: the truth is somewhere in-between. A quality 800w should do from my little knowledge.

Haha! Yeah I know its way to big and powerful for what we need ive never heard my 700w makita struggle at all. I was more just showing the design with the integrated mounts which I think could be good for some people. I couldn’t find a 800w one but I just did now. $200nz for just a spindle though!

Don’t forget that some come without the ~3 phase power supply. My 500w runs of a 12V 10A normal DC and can be speed controlled with a 1-10V pwm module. There is lots of saving there in cash and space/wires.

Edit: When my 500w dies, this will be tested. Can be found cheaper, but not know about you tax in NZ.

Forgive my limited knowledge on these spindles, but do they need the inverter or could you run one off of a 3 phase supply? I’m guessing they must be lower voltage or something? I have 480v 32a 3 phase supply in my shed.

Just scrolled through the listing 220v 3 phase it seems

This kind needs the inverter, but the spindles come with or without (for those that have the VDF already). You can’t just connect your 3 phase.

They are bulky and the setting you can adjust on it do not justify a use on a Maslow.

Go for one that runs on a regular DC power.

VFD is variable frequency drive, controls the spindle speed by generating a variable frequency 3 phase output voltage which may top out around 400 hz instead of the 50 or 60 hz mains frequency.

Interestingly they’re popular for running 3 phase equipment off single phase power, such as your home shop Bridgeport, instead of a phase convertor.

@mooselake Thanks for the info, a little off topic, but I have a power fed resaw it has a 1.5kw 3 phase power feed unit at the moment its slowest feed rate is 7 meters a minute. Is there a simple way (maybe with a vfd)? To slow the 3 phase feed motor down a bit? Thought id ask since you sound knowledgeable. Thanks!

I would check with the motor manufacturer, but as long as they feel running slower won’t damage the motor (there could be a cooling issue, for example) or cause other problems that sounds like a good use.

It might be simpler and cheaper, if you don’t need variable speed, to change the belt pulleys

most of the 500rpm or 800rpm spindles are driven by around a 40 or 50v power supply if I remember correctly. They look like 12v power supplies, but most are higher voltage. they are also typically generate electrical noise so don’t put near other electronics!

Its an older (early ninetys) saw so to change the speed they fitted it with a continuously variable transmission like what a moped scooter has. Goes right up to 25 meters a minute but the slowest itll do is 7. It does have a chain that drives the rollers after that however so I might see if I can get a smaller sprocket, thats a good idea thanks!

A Reeves drive? The mooseshop Grizz wood lathe (soon to he relocated to the expanded Maslow containing shop) has one, as the Hesston 320 hay mower has 2 (one for each drive wheel), and maybe the hydraulically actuated version on the 610 Bobcat qualifies. They’re everywhere.

I don’t know how the increased torque at lower speeds compares to electronically variable speed motors, but they are expensive to rebuild when the diecast lathe pulleys corrode onto a steel shaft. Lube your movable pulleys regularly

Thanks for the suggestion regarding the grease! I think that’s it. I might look into a smaller gear for the output side of the reeves drive which will gear down my final drive ratio.

I just did some testing on some softer aluminum 5251 h32 the 2 flute endmill I was using before clogged after 3 minutes. I then tried 2 different 4mm spiral uncut endmills one a 2 flute one a 3 flute both are spesific aluminium endmills and at my lowest spindle speed of 9500 they both gummed up quick as well. Then I finally tried a 4mm carbide polished single flute (cheap Chinese bit) and it is still happy as after 2.5hrs use and the surface finish is brilliant.

Oh my God you lucky so and so!!!

I’d come close to killing for something like that and a shed…

I have a 2.2kw liquid cooled spindle that can run off single phase 220v or 110v. That’s 3hp spindle power. I don’t think the power available in 480v 3phase at 32a would even be scratched. You’d need to convert that to something less industrial for most ebay and non-commercial components.