For the sake of anyone else who might experience the same issues, I guess I’ll elaborate on my workflow and the trouble-shooting I’ve performed.

Workflow

I start by making my designs in Adobe Illustrator. Once made to my satisfaction, I export the designs as SVG files, and upload them to Easel, modifying them as necessary before exporting them once more as gcode. I then upload the gcode to CNCjs and begin cutting.

So far I have been working only with 1/2" material. Rather than using tabs to support the objects I cut, I tend to use a plastic nailer to secure the wood to a spoil board. Alternatively, and more commonly, I will simply route the edges of an object to 1/4" depth. When all paths have been carved, I will jig-saw my object out from the board, and route the edges to the lines cut by my CNC. I find this can be more time time efficient for repeated cuts and has so-far helped avoid some errors I’ve encountered.

Adobe Illustrator

I set my stroke weight to the size of my router bit, and offset the stroke to the inside out outside of the path depending on where I want the cut to fall. This is merely to remind myself whilst drafting where the cuts will fall. To make sure my joinery sits the way I want, I use dogbones. In Illustrator, this means placing ellipses the size of my router bit on all the areas that need this dogbone. I then take each object in my design and copy / paste it into a new document where I reduce the stroke to 0, and export the Illustrator file to an SVG file.

Easel

I then upload this SVG file to Easel. In Easel, I first select every path, set the depth to the depth of the material, and deselect “use tabs”. This is important because the “use tabs” function is selected by default. And, if like me, you only wish to cut half way through your material, the Maslow will still plunge to the full depth in order to carve around where it believes the tabs should be. Once I’ve deselected the “use tabs” option, I can specify the final depth of my cut, and the cut path (whether it clears a pocket, or falls inside / outside / on the SVG path). Then, for the dogbones, I find the coordinates of each ellipse and replace them with the “Drill” tool. When this has all been done I can export my designs as gcode.

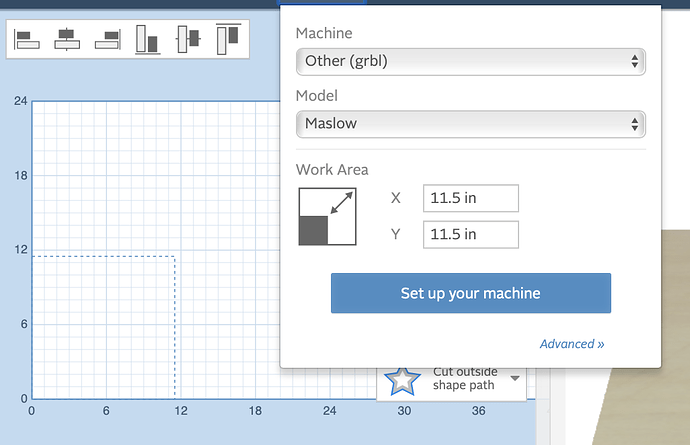

My settings are shown here:

Initially when receiving the error 1 message, I believed it was because my designs contained too much information, and the exported gcode from Easel might have been corrupted slightly upon export. I have been designing some stackable crates, and the first attempts at cutting them meant cutting out multiple sides of said crates in one go. When the error message occurred repeatedly, requiring me to manually resume the operation, we figured we should take a different approach.

Here’s what the first series of passes looked like on Easel:

We then opted to cut one side at a time, which meant outputting each side in its respective coordinates as its own gcode file. I was initially concerned that the objects having negative coordinates would cause an error. However, this one-side-at-a-time approach seemed to miraculously smooth itself out. I managed to cut maybe 5 out of the 7 panels with no error messages whatsoever. Negative coordinates were not generating errors.

I double checked the machines settings of each file and noticed that some of my panels had been assigned a workspace smaller than the actual workspace of the Maslow. I corrected this to properly fit the coordinate grid on Easel.

From:

To:

Unfortunately, the errors have persisted.

To continue using the full sheet of plywood, the next series of cuts is supposed to look like:

Although I have successfully made these cuts, I cannot recall at this moment how frequently, if at all, I received any error messages. If my memory is right, I was able to cut these three panels without a hitch.

I then rotate the sheet of plywood 180 degrees and repeat the whole process. This fills the sheet of plywood with cuts like:

Fortunately, I am able to get these shapes aligned rather nicely. I have a couple of design kinks I’m working out one this next pass and I’m hoping to minimize the error 1 which has been plaguing me. I have attempted to solve this problem based on Easel’s workspace and machine settings, but it seems like the errors occur rather arbitrarily in that regard. I have also had success cutting full shapes without error whether or not they include negative coordinates. I wonder if the errors are occurring at points where the Z axis is being asked to plunge. At this moment in time, it remains unclear. I will try to update any solutions I may find.