I completed my temp frame yesterday and made it through the intial calibration process! All seemed go, so I set out tonight to start cutting out my final frame. I ran into several issues and am going to put them in this one thread (hopefully that’s okay).

I started out in MakerCam and decided to do the first half of my frame, not wanting to attempt it all at once. I manually deleted a bunch of the pieces, and followed the instructions here to create the gCode. After loading it into GroundControl, I realized that I was potentially biting off more than I could chew, and decided to go back and just do the two arms on my first try.

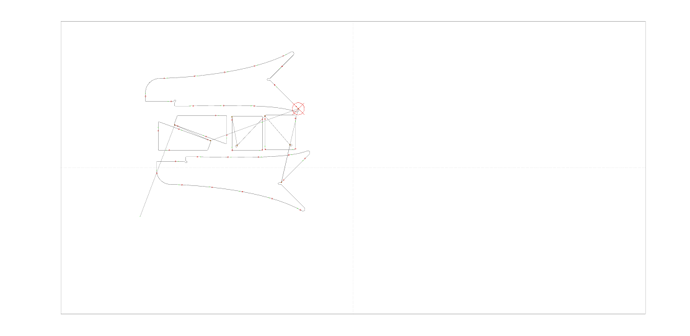

I followed the same instructions, and loaded the file in maslow. Except that this time, my first arm had an outline and the second one didn’t!. Thinking this was a fluke, I tried a few more times with similar results. Finally, I decided to try just one arm. Here’s what that looked like in Ground Control:

Does anyone know what’s going on here?

Okay, second issue is with my Z axis:

Excited to get started, I re-loaded my first G-code containing half of the Maslow frame and decided to jump in.

However, after the first to pieces were “cut” i knew I had a problem. Maslow wasn’t making it all the way through my plywood even though I set the depth to .85". I started watching ground control and keeping an eye on the Z axis. It seems that my machine isn’t able to get the router head low enough. The adjustment screw turns but the router doesn’t seem to go lower. Even though ground control showed the final pass at .85", my cuts are only about 3/8" deep.

Has anyone run into this issue? I suppose I could just extend the router bit a little further, but shouldn’t Z axis be able to lower the router all the way?

Okay, that’s all for now. Thanks for your support! I definitely realize now that I should have waited to start cutting until I was more confident in how things were going to turn out.