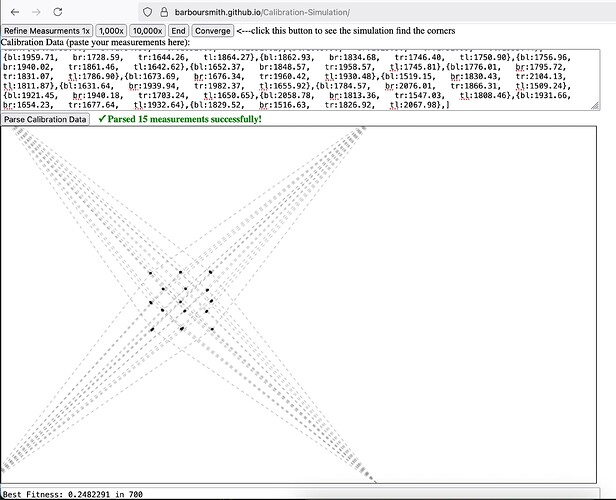

I installed my new gear that arrived yesterday. I have gotten further that I’ve ever gotten with the calibration process, but fitness is still being uncooperative!

Maslow-serial (1).log (34.1 KB)

Attached is the log

Big_Spark wrote:

I installed my new gear that arrived yesterday. I have gotten further that

I¢ve ever gotten with the calibration process, but fitness is still being

uncooperative!

I was fighting bad fitness on a machine today and found that I had the incorrect

Z offsets in place, I was off by ~20mm and that took me from a fitness of ~0.3

to a fitness of ~2.0

David Lang

I don’t think I’ve even touched my z settings. Is that part of the setup process?

Big_Spark wrote:

I don¢t think I¢ve even touched my z settings. Is that part of the setup

process?

it hasn’t been, but we are seeing indications that it needs to be.

The default settings:

tlZ: 100.000000

trZ: 56.000000

blZ: 34.000000

brZ: 78.000000

This is the distance from the bottom of the sled to the bottom of the anchor

when it’s fully retracted

if you have anchors that are not flush with the top of your workpiece, these

numbers are incorrect.

If you have all the arms in the right order, you can then use the

wasteboard thickness and workpiece thickness entries to tell them machine where

the top of the workpiece is relative to the anchors.

i.e. if you have the anchors go to bolts in the concrete with nothing between

the anchors and the concrete, you would need to put in the height of your

wasteboard and the height of your workpiece. You can do this as one entry or two

(the two numbers get added together, we did two so you could use the wasteboard

height for things that don’t change, and the workpiece height for your

workpiece, which will change with different workpieces.

so if you have a 18mm thick wasteboard, but you have printed anchors bolted to

the cement that have 10mm between the concrete and the bottom of the anchor, you

could put in 8mm as the wasteboard thickness. If you then add an 18mm thick

workpiece, then you have a total of 26mm of added height.

You could put all 26mm into wasteboard thickness, all into workpiece thickness,

or all into the Z offsets, making them:

tlZ: 126.000000

trZ: 82.000000

blZ: 60.000000

brZ: 104.000000

when the belts are close to flat, the error introduced by having the Z offsets

wrong is much less than when they are angled.

In my case, I had a small frame (which makes the angles worst) but each anchor

at different heights. changing the Z offset from -12 to 10 (and I think the

correct value is ~6-8) made a significant difference to me.

this is new, and we don’t have a lot of people using this ‘in the field’ and

reporting results, so this hasn’t yet been put in the main instructions or the

UI. But a lot of us think that this will help, so when we see someone

struggling, we need to suggest checking the offsets to make sure they match

reality, and to try adjusting them when they don’t to report if it makes enough

of a difference to be worth adding to the instructions/UI

David Lang

Looking at the log I’m not seeing anything catastrophically wrong, it just seems like the measurements aren’t quite good enough to find good anchor point locations.

Did it seem like all of the belts were tight at each measurement? Did anything at all seem off during the measurement process?

The only thing I noticed was the sled would lift from the table. Yes, the belts stayed tight.

My frame is a variation of the original Maslow frame. Think I will readjust my anchor points based on D. Lang notes above.

Big_Spark wrote:

The only thing I noticed was the sled would lift from the table. Yes, the belts stayed tight.

try reducing the current limits, find the lowest current that reliably retracts

the belts (and when you do a calibration, make sure the belts pull tight at

every point)

My frame is a variation of the original Maslow frame. Think I will readjust my anchor points based on D. Lang notes above.

I don’t remember if I asked you to measure all 6 distances between anchors and

do a manual calibration or not. If I didn’t, that may be a useful thing to do.

David Lang

David, do you have further instructions on how to do the manual calibration?

Do you think my belt tension could also cause the fitness issue?

measure the distances betwen anchors (all 5 diensions) and enter them in

the text then shows the anchor location

David Lang

Big_Spark wrote:

Big_Spark wrote:

Do you think my belt tension could also cause the fitness issue?

it can.

if the tension is too low, the belts don’t pull tight and the data for that

measurement point isn’t accurage

if the tension is too high, the belts stretch and the data for that measurement

point isn’t accurate

in general, it seems like you want the lowest tension that you can get away

with.

David Lang

Hi David (@dlang),

I’ve been working to understand the Z offset values (tlZ, trZ, blZ, brZ) based on your explanation, and I think I’ve figured out what they actually represent, but I’d like confirmation.

You wrote:

“This is the distance from the bottom of the sled to the bottom of the anchor when it’s fully retracted”

and

The default settings:

tlZ: 100.000000

trZ: 56.000000

blZ: 34.000000

brZ: 78.000000

But if a typical horizontal installation has anchors all at the same height (~10mm above the sled or work surface) then wouldn’t these offsets all be the same value? The fact that the defaults are different, must mean that the z-offset takes into account the belt height at the sled.

My Analysis

Setup: Maslow 4.1, horizontal installation on cement with anchors, using risers at anchors with various heights to achieve level(ish) belts.

Measurements: Distance from top of belt to bottom of sled (with Z-axis bottomed out) at the router: TL: 114.37mm, TR: 70.63mm, BL: 49.20mm, BR: 90.87mm

Testing the theory: If Z offset default represents “bottom of belt on sled to bottom belt at a 10mm high anchor” and no workpiece thickness (routing on ground):

| Corner | Z Default | My Maslow (top of belt to work surface) | -Belt (6.2mm) | -Anchor Height (10mm) | Diff mm | Diff % |

|---|---|---|---|---|---|---|

| TL | 100 | 114.37 | 108.17 | 98.17 | -1.83 | -1.83% |

| TR | 56 | 70.63 | 64.43 | 54.43 | -1.57 | -2.80% |

| BL | 34 | 49.20 | 43.00 | 33.00 | -1.00 | -2.94% |

| BR | 78 | 90.87 | 84.67 | 74.67 | -3.33 | -4.27% |

The calculations match the defaults within 2-4%, which suggests this interpretation of how the defaults are determined is correct.

My Calculated Z Offsets

For my setup with risers:

Z offset = (Anchor height top of belt) - (Sled height top of belt) - (Material height)

Where:

-

Anchor height top of belt (floor to top of belt): TL=152.72, TR=109.45, BL=92.11, BR=130.87mm

-

Sled height top of belt w/ z bottomed (my maslow): TL=114.37, TR=70.63, BL=49.20, BR=90.87mm

-

Material height: 42.86mm (1” spoilboard + 22/32” workpiece)

Calculations:

-

tlZ: 152.72 - 114.37 - 42.86 = -4.51

-

trZ: 109.45 - 70.63 - 42.86 = -4.04

-

blZ: 92.11 - 49.20 - 42.86 = 0.05

-

brZ: 130.87 - 90.87 - 42.86 = -2.86

Spoil board & Work thickness

I assume I then update the fluidNC settings for /Maslow_spoilboardThickness & /Maslow_workThickness BEFORE calibration and any time the setup changes (different spoil board or work thickness)?

Request

Could you confirm if this interpretation and calculation method is correct? A definitive measurement procedure would be incredibly helpful for the community.

Thanks for all your help!

Brian Peterson wrote:

“This is the distance from the bottom of the sled to the bottom of the anchor when it’s fully retracted”

and

The default settings:

tlZ: 100.000000

trZ: 56.000000

blZ: 34.000000

brZ: 78.000000But if a typical horizontal installation has anchors all at the same height

(~10mm above the sled or work surface) then wouldn’t these offsets all be the

same value?

No, the arms are at different heights, so the distance from the bottom of the

sled to the bottom of the belt end of the lowest belt when fully retracted into

the arm is going to be less that the distance from the bottom of the sled to the

bottom of the belt end of the highest belt when fully retracted.

The fact that the defaults are different, must mean that the

z-offset takes into account the belt height at the sled.

ahh, I see the confusion now, I said anchor which you took to be the bolt on the

floor when I was thinking the plastic at the end of the belt.

My Analysis

Setup: Maslow 4.1, horizontal installation on cement with anchors, using risers at anchors with various heights to achieve level(ish) belts.

Measurements: Distance from top of belt to bottom of sled (with Z-axis bottomed out) at the router: TL: 114.37mm, TR: 70.63mm, BL: 49.20mm, BR: 90.87mm

Testing the theory: If Z offset default represents “bottom of belt on sled to bottom belt at a 10mm high anchor” and no workpiece thickness (routing on ground):

Corner Z Default My Maslow (top of belt to work surface) -Belt (6.2mm) -Anchor Height (10mm) Diff mm Diff % TL 100 114.37 108.17 98.17 -1.83 -1.83% TR 56 70.63 64.43 54.43 -1.57 -2.80% BL 34 49.20 43.00 33.00 -1.00 -2.94% BR 78 90.87 84.67 74.67 -3.33 -4.27% The calculations match the defaults within 2-4%, which suggests this interpretation of how the defaults are determined is correct.

My Calculated Z Offsets

For my setup with risers:

Z offset = (Anchor height top of belt) - (Sled height top of belt) - (Material height)

Where:

Anchor height top of belt (floor to top of belt): TL=152.72, TR=109.45, BL=92.11, BR=130.87mm

Sled height top of belt w/ z bottomed (my maslow): TL=114.37, TR=70.63, BL=49.20, BR=90.87mm

Material height: 42.86mm (1” spoilboard + 22/32” workpiece)

Calculations:

tlZ: 152.72 - 114.37 - 42.86 = -4.51

trZ: 109.45 - 70.63 - 42.86 = -4.04

blZ: 92.11 - 49.20 - 42.86 = 0.05

brZ: 130.87 - 90.87 - 42.86 = -2.86

Spoil board & Work thickness

I assume I then update the fluidNC settings for /Maslow_spoilboardThickness & /Maslow_workThickness BEFORE calibration and any time the setup changes (different spoil board or work thickness)?

yes, the total height between the bottom of the belt end when fully retracted

and the bottom of the belt end when attached to the anchor can be split up

between spoilboardthickness, workthickness, and the Z offsets.

It used to be that you would have to adjust all 4 z offsets to account for this,

but we added the other two values to make it easier to adjust.

The idea is the the:

individial Z offsets account for anything specific to an arm (for example, one

place I am setting up a maslow in in the ally behind a local makerspace, there

are three sections of concrete, and they are not all in the same plane, let

alone level, so the Z offsets for that use have to account for the unlevel

ground as well as the different heights on the sled.

spoilboardthickness accounts for offsets that are stable with your setup, but

could change (if you normally use a 1" foam spoilboard and now use a 2"

spoilboard for example)

which leaves the workthickness to be a number that you can directly measure and

enter, no calculations needed.

but you could combine the spoilboard and workpiece thickness into a single

number and put it in either spot, it makes no difference.

Could you confirm if this interpretation and calculation method is correct? A definitive measurement procedure would be incredibly helpful for the community.

Yes, you have it correct

David Lang

oh yea, now I see the confusion. I was definitely thinking you were talking about the anchor points, not the belt ends retracted in the router.

Yes, you have it correct

David Lang

Thank you

this should be arriving today, which should make it much easier to measure the

heights of things consistantly (with the arms so short, it’s hard to get a

reliable measurement of a height at the sled end as the sled is in the way)

David Lang

I used a set of digital calipers with a depth gauge. I applied tension to the belts and measured from the top of the belt to the work surface or floor for the anchors.

Hello, Been quite some time since I’ve piddled with my router. I had more pressing projects that needed addressed before I could sit down and focus on this thing. I’m finally getting freed up and hoping to dedicate time to this machine and get it resolved once and for all.

I do have one new question. Even with both clamps tight my router is still turning freely in the housing. Has anyone else experienced this? Do you have a good solution?

Thank you to everyone that has helped me out.

Interestingly I hadn’t encountered that issue until someone else posted it yesterday:

Same issue, I just ordered a new clamp as mine cracked as well.