Ok. Here is the deal. According to the datasheet on the power SO chips used in the stock board:

Non repetitive max 3.0amps

Repetitive (80 on 20 off) 2.5 amps

Dc operation 2.0 amps

But later in the datasheet they mention the technique to add current capability. Parallel use of chip (adding second in parallel will increase amperage) but the main section list the values i gave you. Plus each states per channel. Which is why they list max at 4 amps under chip description.

Either way I think you are good to go, especially if just using 2 motors, one on each chip for now.

Your hookup. This was where I messed up because I only have 10 min time slots to do this stuff and casually looked at the functional placement schematic when making cables and switched the dc power with the ppr lines, doh. After Bar showed me that the schematic was not wrong but if use to reading how I did and not tracing (my fault), you would get them mixed up.

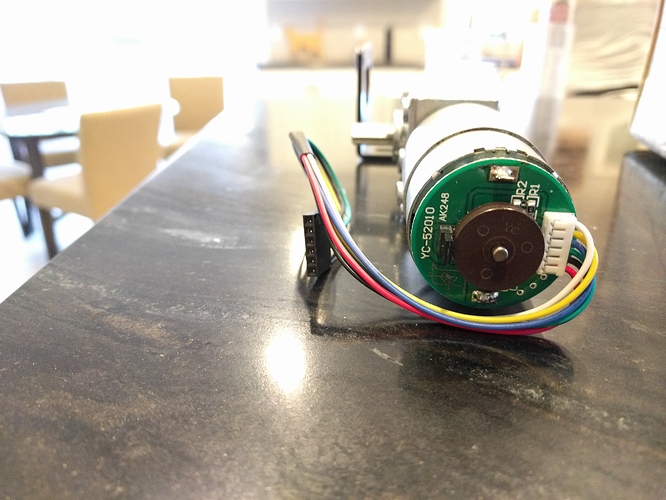

So, if going off the partial picture I saw of the encoder wiring for yours you can see it is not the same as the board.

So the great part is that all cables that have connections like these that I have seen, are easy to rearrange. Just use a pin or tool to push on the showing metal and lift the plastic gently right behind it as you pull out the wire. Then put back in the correct ones and they will snap. Hopefully having voltage on the encoder meant for the motor did not fry encoder but I do doubt it. If so tell me cause I was able to replace a hall sensor no problem…but can get touchy.

The pinout for your board (Maslow) is as follows:

From the top looking down and power plug to the right:

1.m

2.m

3.g. note 3 and 4 might be switched (Not in front of me to verfy)

4.3.3-5v

5.en in

6.en in

BUT I KNOW FOR A FACT THAT BOTH MOTOR PINS ARE AT THE TOP OF THE FEMALE PLUG ON BOARD.

BOTH OF THE ENCODERS ARE ON THE 2 BOTTOM PINS AND THE GROUND AND V FOR ENCODERS ARE IN THE MIDDLE.

If you have any questions, feel free to ask. I do not see why you could not get them set up with what you have assuming these are 2.4 amp peak motors…if higher than that…no, but you can get a cheap 5-7 amp board no problem.

Best of luck.

If you need the actual mapping just ask, I am not in front of them and would need to see your encoder. My brain is scrambled a bit so not remembering specific plus and minus. But fact is the pinout I gave is correct. Actually back when I first set it up and was shown my error, many others chimed in and said they would have done the same thing i did based on the posted schematic (Not placement schematic …but initially read it as one)

Regards,

Todd