Alternate titles:

tilt the Maslow 4.1 wilt

wheelie the Maslow 4.1 will surely

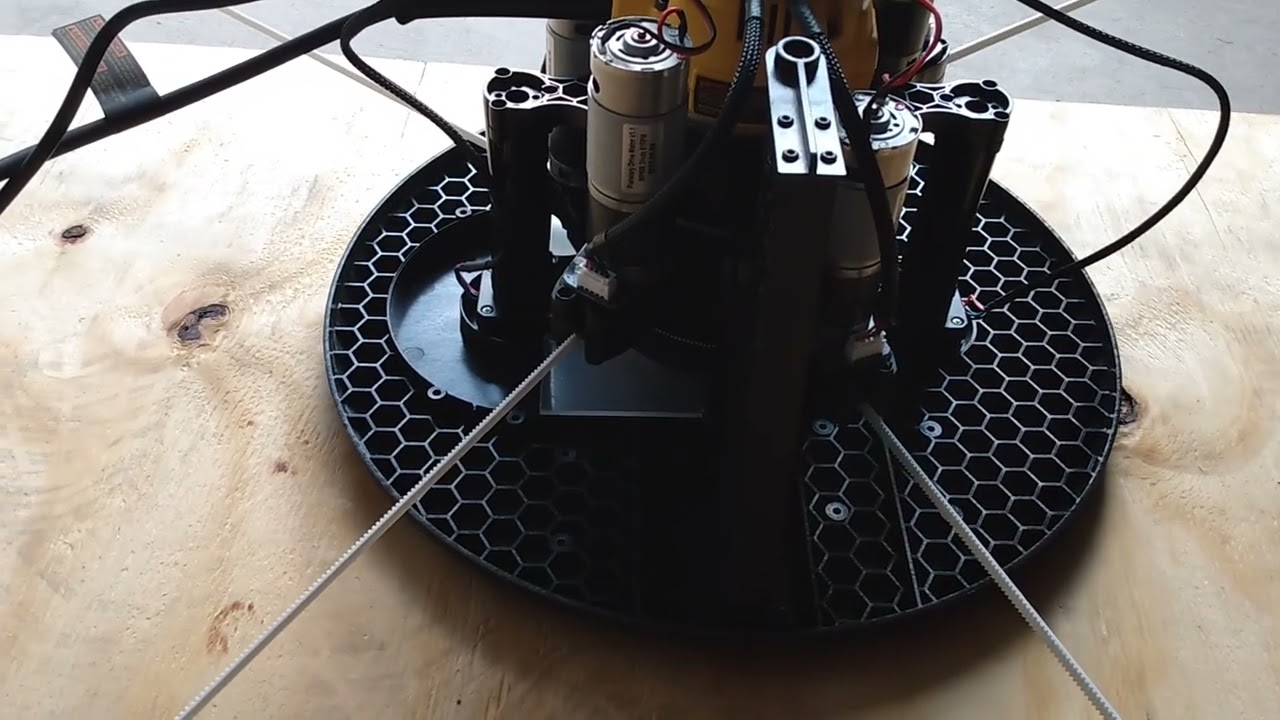

What am I missing here? I haven’t even cut any material yet; I’m just trying (in vain) to satisfy myself (before wasting material) that the Maslow 4.1 could cut something well.

FW is v1.15

I started with a 300mm/min feed rate (seen on this forum), and then halved it again for the provided video. The Maslow 4.1 sled hops/tilts around as it travels. Even if I slowed the feed rate further, it seems the added resistance of the router bit plowing through the material would make the phenomena present (or worse) all the same.

Perhaps the sled needs more weight, but I wasn’t under the impression that the 4.1 (particularly in horizontal mode) used bricks and it is not clear where they would mount securely. I could try decreasing tension, but the router bit movement would just take up the resultant slack and drive accuracy down further. I’ve seen one forum poster extolling the virtues of greasing the sled or otherwise reducing friction on the sled underside, but again, the router bit would surely act to tilt the sled and make a mockery of this, reduced friction or not.

My setup is a horizontal ~3000 mm H x ~3800 mm W on a concrete floor which I chose based on available space and the accuracy calculator showing nearly all green on a 4x8 sheet except the extreme corners.

Since I don’t have a router bit installed, I’ve homed the Z-axis by letting it travel as far down as it can go, and then backed it up 5mm (which could be a more rosy condition than when a router bit is installed and the router has be higher).

Here’s what the most recent 7x7 calibration (340 W x 170 H grid) reported:

Calibration values:

Fitness: 1.9773150552966041

Maslow_tlX: -12.3

Maslow_tlY: 2891.0

Maslow_trX: 3887.8

Maslow_trY: 2896.3

Maslow_blX: 0.0

Maslow_blY: 0.0

Maslow_brX: 3882.1

Maslow_brY: 0.0

Extend Distance is 2300, Retraction Force is 1300, and Calibration Force is 1000

It feels like the design depends on the belts acting on the fulcrum of a lever, whilst meanwhile the sled base and router bit have the mechanical advantage over the belts by being on the opposite side of that lever.

I presume it is not a coincidence that the hop/tilt is more egregious when heading towards the upper left, since upper left belt cog is highest and the lower left belt cog is lowest, providing increased torque for the assembly to tilt.

Would I be right in thinking that the earlier generations of Maslow had its chain mounted at the base of the sled (and at the same height) to reduce such forces?