Bar, JitM, thanks for taking the time.

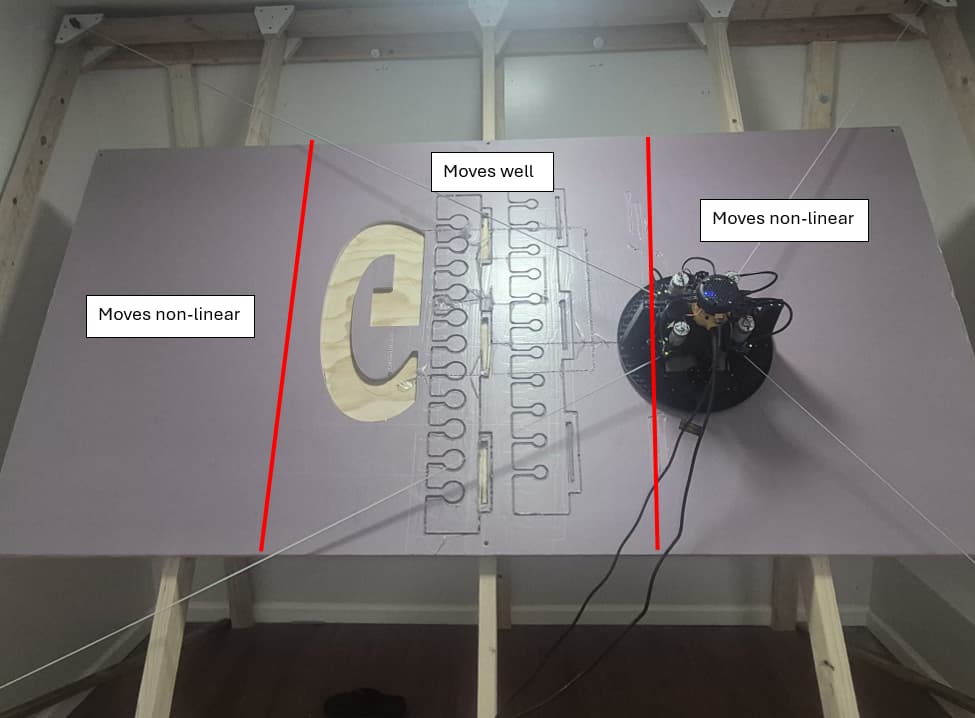

I successfully ran the calibration with calibration force 1200, 1200x800 and 7x7 grid. I was able to make a successful cut, before getting the position error: “Position error on Top Right axis exceeded 15mm while running”.

Today I try to repeat the calibration with these settings but the calibration didnt converged. I tried with the default calibration 500x500 and 900 force, and it succeeded. Nevertheless, I tried to cut a piece, but the position error showed up again.

I’m running out of ideas.

See log below, if it helps:

Serial Messages

Index.html Version: 1.07

[MSG:INFO: Channel auto report interval set to 50 ms]

[MSG:INFO: FluidNC v3.0.x (noGit)]

[MSG:INFO: Compiled with ESP32 SDK:v4.4.7-dirty]

[MSG:INFO: Local filesystem type is littlefs]

[MSG:INFO: Configuration file:maslow.yaml]

[MSG:INFO: Machine Maslow S3 Board]

[MSG:INFO: Board Maslow]

[MSG:INFO: UART1 Tx:gpio.1 Rx:gpio.2 RTS:NO_PIN Baud:115200]

[MSG:INFO: SPI SCK:gpio.12 MOSI:gpio.11 MISO:gpio.13]

[MSG:INFO: SD Card cs_pin:gpio.10 detect:NO_PIN freq:8000000]

[MSG:INFO: Stepping:Timed Pulse:4us Dsbl Delay:0us Dir Delay:0us Idle Delay:240ms]

[MSG:INFO: Axis count 3]

[MSG:INFO: Axis X (-2438.400,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: Axis Y (-1219.200,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: Axis Z (-100.000,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: tmc_2209 UART1 Addr:0 Step:gpio.15 Dir:gpio.16 Disable:NO_PIN R:0.110]

[MSG:INFO: Motor1]

[MSG:INFO: tmc_2209 UART1 Addr:1 Step:gpio.46 Dir:gpio.38 Disable:NO_PIN R:0.110]

[MSG:INFO: Z Axis driver test passed]

[MSG:INFO: Z2 Axis driver test passed]

[MSG:INFO: Kinematic system: Cartesian]

[MSG:INFO: Using spindle NoSpindle]

[MSG:INFO: Connecting to STA SSID:dell]

[MSG:INFO: Connecting.]

[MSG:INFO: Connecting..]

[MSG:INFO: Connected - IP is 192.168.137.164]

[MSG:INFO: WiFi on]

[MSG:INFO: Start mDNS with hostname:http://maslow.local/]

[MSG:INFO: SSDP Started]

[MSG:INFO: HTTP started on port 80]

[MSG:INFO: Telnet started on port 23]

[MSG:INFO: Channel auto report interval set to 50 ms]

Release Tension

[MSG:INFO: Requesting state change from Unknown to Releasing Tension]

[MSG:INFO: Succeeded]

[MSG:INFO: Requesting state change from Releasing Tension to Unknown]

[MSG:INFO: Succeeded]

Release Tension

[MSG:INFO: Requesting state change from Unknown to Releasing Tension]

[MSG:INFO: Succeeded]

[MSG:INFO: Requesting state change from Releasing Tension to Unknown]

[MSG:INFO: Succeeded]

[MSG:WARN: Bad connection on Top Right encoder, failed to read 1 times in the last second]

[MSG:ERR: Emergency stop. Update function not being called enough.1001ms since last call]

Retract All

[MSG:INFO: Retracting all belts]

[MSG:INFO: Requesting state change from Unknown to Retracting Belts]

[MSG:INFO: Succeeded]

[MSG:INFO: Bottom Left pulled tight with offset -1586.385]

[MSG:INFO: Top Left pulled tight with offset -1601.351]

[MSG:INFO: Bottom Right pulled tight with offset -1813.679]

[MSG:INFO: Top Right pulled tight with offset -1839.649]

[MSG:INFO: Requesting state change from Retracting Belts to Belts Retracted]

[MSG:INFO: Succeeded]

Extend All

[MSG:INFO: Extending all belts]

[MSG:INFO: Requesting state change from Belts Retracted to Extending Belts]

[MSG:INFO: Succeeded]

[MSG:INFO: All belts extended to 1720.000mm]

[MSG:INFO: Requesting state change from Extending Belts to Belts Extended]

[MSG:INFO: Succeeded]

Calibrate

[MSG:INFO: Requesting state change from Belts Extended to Calibrating]

[MSG:INFO: Setting z-stop position]

[MSG:INFO: Machine Position found as X: -3.589 Y: -48.514]

[MSG:INFO: Succeeded]

[MSG:INFO: Measured waypoint 0]

[MSG:INFO: Center point off by: TL: 0.000 TR: 0.000 BL: 5.567 BR: 4.317]

[MSG:INFO: Machine Position computed as X: -3.401 Y: -30.189]

[MSG:INFO: Measuring Frame Flex]

[MSG:ERR: Measurement error, measurements are not within 2.5 mm of each other, trying again]

[MSG:INFO: Max deviation: 4.037]

[MSG:INFO: Bottom Right 1871.035]

[MSG:INFO: Bottom Right 1871.046]

[MSG:INFO: Bottom Right 1871.089]

[MSG:INFO: Bottom Right 1871.089]

[MSG:INFO: Top Right 1872.914]

[MSG:INFO: Top Right 1872.914]

[MSG:INFO: Top Right 1873.032]

[MSG:INFO: Top Right 1873.107]

[MSG:INFO: Top Left 1860.421]

[MSG:INFO: Top Left 1860.421]

[MSG:INFO: Top Left 1856.383]

[MSG:INFO: Top Left 1856.351]

[MSG:INFO: Bottom Left 1839.900]

[MSG:INFO: Bottom Left 1839.911]

[MSG:INFO: Bottom Left 1839.922]

[MSG:INFO: Bottom Left 1839.911]

[MSG:INFO: Flex measurement: TLBR: 2.171 TRBL: 3.852]

[MSG:INFO: Measured waypoint 1]

[MSG:INFO: Measured waypoint 2]

[MSG:INFO: Measured waypoint 3]

[MSG:INFO: Measured waypoint 4]

[MSG:INFO: Measured waypoint 5]

[MSG:INFO: Requesting state change from Calibrating to Calibration Computing]

[MSG:INFO: Succeeded]

CLBM:[{bl:1860.42, br:1842.31, tr:1872.87, tl:1870.88},{bl:1979.30, br:1727.53, tr:1759.09, tl:1988.14},{bl:2064.47, br:1818.07, tr:1666.28, tl:1913.20},{bl:1951.45, br:1930.80, tr:1783.01, tl:1788.05},{bl:1836.47, br:2047.41, tr:1910.46, tl:1665.15},{bl:1740.67, br:1965.98, tr:1992.32, tl:1751.31},]

Computing… This may take several minutesFitness: 0.1519213 in 100

Fitness: 0.2124598 in 200

Fitness: 0.2449519 in 300

Fitness: 0.2610459 in 400

Fitness: 0.3422268 in 500

Fitness: 0.5618403 in 600

Fitness: 0.9521849 in 700

Fitness: 1.2623125 in 800

Fitness: 1.3555364 in 900

Fitness: 1.3555364 in 1000

Fitness: 1.3555364 in 1100

Fitness: 1.3555364 in 1200

Fitness: 1.3555364 in 1300

Fitness: 1.3555364 in 1400

Fitness: 1.3555364 in 1500

Fitness: 1.3555364 in 1600

Fitness: 1.3555364 in 1700

Fitness: 1.3555364 in 1800

Calibration values:

Fitness: 1.3555362948909566

Maslow_tlX: 28.2

Maslow_tlY: 2018.3

Maslow_trX: 3133.9

Maslow_trY: 2024.5

Maslow_blX: 0.0

Maslow_blY: 0.0

Maslow_brX: 3144.6

Maslow_brY: 0.0

A command to save these values has been successfully sent for you. Please check for any error messages.

Calibrate

[MSG:INFO: Requesting state change from Calibration Computing to Calibrating]

[MSG:INFO: Setting z-stop position]

[MSG:INFO: Machine Position found as X: -136.390 Y: -37.975]

[MSG:INFO: Succeeded]

[MSG:INFO: Measured waypoint 6]

[MSG:INFO: Measured waypoint 7]

[MSG:INFO: Measured waypoint 8]

[MSG:INFO: Measured waypoint 9]

[MSG:INFO: Measured waypoint 10]

[MSG:INFO: Measured waypoint 11]

[MSG:INFO: Measured waypoint 12]

[MSG:INFO: Measured waypoint 13]

[MSG:INFO: Measured waypoint 14]

[MSG:INFO: Requesting state change from Calibrating to Calibration Computing]

[MSG:INFO: Succeeded]

CLBM:[{bl:1860.42, br:1842.31, tr:1872.87, tl:1870.88},{bl:1979.30, br:1727.53, tr:1759.09, tl:1988.14},{bl:2064.47, br:1818.07, tr:1666.28, tl:1913.20},{bl:1951.45, br:1930.80, tr:1783.01, tl:1788.05},{bl:1836.47, br:2047.41, tr:1910.46, tl:1665.15},{bl:1740.67, br:1965.98, tr:1992.32, tl:1751.31},{bl:1869.22, br:1873.95, tr:1861.83, tl:1838.77},{bl:1747.23, br:1741.38, tr:2000.36, tl:1986.05},{bl:1531.18, br:1965.31, tr:2199.63, tl:1805.35},{bl:1669.50, br:2084.03, tr:2073.82, tl:1641.13},{bl:1829.58, br:2212.48, tr:1963.85, tl:1500.83},{bl:2011.44, br:2014.40, tr:1738.53, tl:1714.74},{bl:2215.85, br:1832.97, tr:1517.44, tl:1942.47},{bl:2091.48, br:1670.40, tr:1649.64, tl:2054.32},{bl:1974.64, br:1529.08, tr:1812.29, tl:2186.27},]

Computing… This may take several minutesFitness: 0.5919824 in 100

Fitness: 0.5920835 in 200

Fitness: 0.5920835 in 300

Fitness: 0.5920835 in 400

Fitness: 0.5920835 in 500

Fitness: 0.5920835 in 600

Fitness: 0.5920835 in 700

Fitness: 0.5920835 in 800

Fitness: 0.5920835 in 900

Fitness: 0.5920835 in 1000

Fitness: 0.5920835 in 1100

Calibration values:

Fitness: 0.5920834885085475

Maslow_tlX: 21.8

Maslow_tlY: 2018.3

Maslow_trX: 3132.6

Maslow_trY: 2024.5

Maslow_blX: 0.0

Maslow_blY: 0.0

Maslow_brX: 3136.4

Maslow_brY: 0.0

A command to save these values has been successfully sent for you. Please check for any error messages.

Calibrate

[MSG:INFO: Requesting state change from Calibration Computing to Calibrating]

[MSG:INFO: Setting z-stop position]

[MSG:INFO: Machine Position found as X: 249.707 Y: -240.012]

[MSG:INFO: Succeeded]

[MSG:INFO: Measured waypoint 15]

[MSG:INFO: Measured waypoint 16]

[MSG:INFO: Requesting state change from Calibrating to Calibration Computing]

[MSG:INFO: Succeeded]

CLBM:[{bl:1860.42, br:1842.31, tr:1872.87, tl:1870.88},{bl:1979.30, br:1727.53, tr:1759.09, tl:1988.14},{bl:2064.47, br:1818.07, tr:1666.28, tl:1913.20},{bl:1951.45, br:1930.80, tr:1783.01, tl:1788.05},{bl:1836.47, br:2047.41, tr:1910.46, tl:1665.15},{bl:1740.67, br:1965.98, tr:1992.32, tl:1751.31},{bl:1869.22, br:1873.95, tr:1861.83, tl:1838.77},{bl:1747.23, br:1741.38, tr:2000.36, tl:1986.05},{bl:1531.18, br:1965.31, tr:2199.63, tl:1805.35},{bl:1669.50, br:2084.03, tr:2073.82, tl:1641.13},{bl:1829.58, br:2212.48, tr:1963.85, tl:1500.83},{bl:2011.44, br:2014.40, tr:1738.53, tl:1714.74},{bl:2215.85, br:1832.97, tr:1517.44, tl:1942.47},{bl:2091.48, br:1670.40, tr:1649.64, tl:2054.32},{bl:1974.64, br:1529.08, tr:1812.29, tl:2186.27},{bl:1745.33, br:1730.75, tr:2002.91, tl:1996.27},{bl:1867.97, br:1864.10, tr:1862.96, tl:1848.12},]

Computing… This may take several minutesFitness: 0.5279866 in 100

Fitness: 0.5279866 in 200

Fitness: 0.5279866 in 300

Fitness: 0.5279866 in 400

Fitness: 0.5279866 in 500

Fitness: 0.5279866 in 600

Fitness: 0.5279866 in 700

Fitness: 0.5279866 in 800

Fitness: 0.5279866 in 900

Fitness: 0.5279866 in 1000

Calibration values:

Fitness: 0.5279865612636535

Maslow_tlX: 21.8

Maslow_tlY: 2018.3

Maslow_trX: 3132.6

Maslow_trY: 2024.5

Maslow_blX: 0.0

Maslow_blY: 0.0

Maslow_brX: 3136.0

Maslow_brY: 0.0

A command to save these values has been successfully sent for you. Please check for any error messages.

Calibrate

[MSG:INFO: Requesting state change from Calibration Computing to Calibrating]

[MSG:INFO: Setting z-stop position]

[MSG:INFO: Machine Position found as X: 0.164 Y: -5.241]

[MSG:INFO: Succeeded]

[MSG:INFO: Requesting state change from Calibrating to Ready To Cut]

[MSG:INFO: Succeeded]

JogTo: '$J=G91F2500X50

’

JogTo: '$J=G91F2500X50

’

JogTo: '$J=G91F2500X50

’

JogTo: '$J=G91F2500X50

’

JogTo: '$J=G91F2500X50

’

JogTo: '$J=G91F2500X50

’

JogTo: '$J=G91F2500Y100

’

JogTo: '$J=G91F2500Y100

’

JogTo: '$J=G91F2500Y100

’

JogTo: '$J=G91F2500Y100

’

JogTo: '$J=G91F2500Y50

’

JogTo: '$J=G91F2500Y-250

’

JogTo: '$J=G91F2500Y-250

’

JogTo: '$J=G91F2500Y-250

’

JogTo: '$J=G91F2500Y-100

’

JogTo: '$J=G91F2500Y-100

’

JogTo: '$J=G91F2500Y-50

’

JogTo: '$J=G91F2500Y-50

’

JogTo: '$J=G91F2500Y-50

’

Home pos set for: X

Home pos set for: Y

[G54:300.163,-600.150,30.400]

[G54:300.163,-655.237,30.400]

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z5

’

JogTo: '$J=G91F300Z-5

’

JogTo: '$J=G91F300Z-15

’

JogTo: '$J=G91F300Z-5

’

JogTo: '$J=G91F300Z-5

’

JogTo: '$J=G91F300Z-2

’

JogTo: '$J=G91F300Z-2

’

JogTo: '$J=G91F300Z-1

’

JogTo: '$J=G91F300Z-1

’

Home pos set for: Z

[G54:300.163,-655.237,34.000]

[MSG:WARN: Position error on Top Right axis exceeded 15mm while running. Error is 15.029mm Counter: 1]

[MSG:WARN: Previous error was 15.029mm]

[MSG:WARN: Position error on Top Right axis exceeded 15mm while running. Error is 15.044mm Counter: 2]

[MSG:WARN: Previous error was 15.044mm]

[MSG:WARN: Position error on Top Right axis exceeded 15mm while running. Error is 15.050mm Counter: 3]

[MSG:WARN: Previous error was 15.050mm]

[MSG:WARN: Position error on Top Right axis exceeded 15mm while running. Error is 15.088mm Counter: 4]

[MSG:WARN: Previous error was 15.088mm]

[MSG:WARN: Position error on Top Right axis exceeded 15mm while running. Error is 15.126mm Counter: 5]

[MSG:WARN: Previous error was 15.126mm]

[MSG:WARN: Position error on Top Right axis exceeded 15mm while running. Error is 15.164mm Counter: 6]

[MSG:WARN: Previous error was 15.164mm]

[MSG:ERR: Emergency stop! Stopping all motors]

[MSG:WARN: The machine will not respond until turned off and back on again]

[MSG:INFO: Reset during file job at line: 32]

[MSG:ERR: Position error > 15mm while running. E-Stop triggered.]