I picked up the Cen-Tec antistatic hose that everyone seems to like. I am struggling with how to attach it - do any the dust collectors on the not-shop fit it? Seems like a dust collector that points up for hanging the hose from a pulley would be better than a side fit. Anyone using the Cen-Tec that can shed some light? I have a great 3d printer but not sure how to even start to make my own dust adatper. TIA!

Would anyone be willing and able to upload the Not Shop files to the bambulabs makerworld.com site?

gilles.v.79 wrote:

Novice question here… Is my understanding correct that the M4’s design

causes the belts to originate at four different heights?

That is correct

And that, on a strictly horizontal frame, the four corner-mounted devices with

their anchors ensure each belt remains perfectly horizontal, leading to a

significant fitness increase?

that depends on your frame. (and not enough testing to be sure of the

advantages)

many of us believe that if the belts are close to horizontal it reduces error

and therefor improves fitness. depending on your frame the belt anchors may all

be at the same height (for example, the ‘official’ frame design), or they may be

a different heights (the ‘super simple frame’ design), and then the actual

height can vary depending on your spoilboard/workpiece thickness compared to

what the offsets are.

David Lang

Some of the tools etc I have made for the M4

Alternative Button pusher, more space to change bits & harder to forget:

M4_Alt_SpindleLock.step (91.6 KB)

Inner Support for arms(4) and spacer(2) to separate bearings. A couple of mm shorter than existing Arms.

M4InnerSupport.step (455.1 KB)

M4InnerSpacer.step (10.5 KB)

Wanted to call this out, I printed one, it’s freaking fantastic, easy to print, just works. THANK YOU! Totally should go into the not shop.

I had great difficulty getting the Cen-Tec adapter to stay on the end of the 1.5" dust collector model. I used Fusion 360 to remix it with a Cen-Tec adapter model and have posted it on Printables.

An updated version of the Spindle Lock

M4_Alt_SpindleLock.step (103.7 KB)

Don’t like this as much, uprights get in the way. Later version below with holder.

https://abundance.maslowcnc.com/run/IDAbbott/M4_Alt_SpindleLock

I have designed a 2mm pencil lead holder. Feel free to use. Thanks to Jeeprinter for the idea of replacing the collet

PencilHolder.step (178.7 KB)

There is a spring (diameter 6mm x 25mm long) in the top of the holder, with a 3D printed insert which puts pressure on the lead. To prevent the lead falling out when router lifted, I made a metal tensioner from a fruit tin can. Predrill the hole before cutting out. Nut sits behind metal tensioner; The tensioner pushes against the pencil lead. Additional nut is used to stop screw going in too far. Strongly advise not using wife’s sewing scissors to cut this out (very effective though). Spring is held in place by hot glue. Sorry, didn’t take a photo of this before sealing up. Quite effective for drawing.

Used in place of the router’s collet. Take off the Collet and replace. The internal print is tapered so push it up until it engages and then turn to lock

Very nice!!

What CAD software is that?

You may have heard of it, it’s called Abundance Beta. I am really happy with it.

Hahaha I THOUGHT I recognized that grid in the background.

Awesome!!!

It is so so cool to see someone else using it. Thank you for sharing!

I’m not sure how to share the Molecules from Abundance, do I just copy the URL it generates?

Yup! That’s all there is to it ![]()

That page will include any inputs that you have on the top level as parameters for the user to edit, and any exports that you have as download options so it’s easy to share a link which lets the person who opens the link make some quick parameter changes and then download a .svg, .stl, .step, or gcode file

@bar Could you please upload this missing file? When disassembling to sand the bearing surface of the spools several of my rollers were broken. I’m sure that isn’t helping with the friction and increasing force issues.

I don’t know if there will be a 4.2 at some point, but I’d recommend bulking up the connection between the ends of the roller and the body. It might even be advantageous to add a fillet between the body and ends if there’s room.

Can you snap a picture of those if it’s not too late?

Just uploaded it! Thanks for catching that

Can you snap a picture of those if it’s not too late?

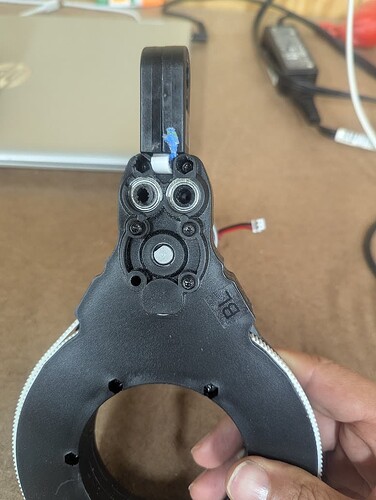

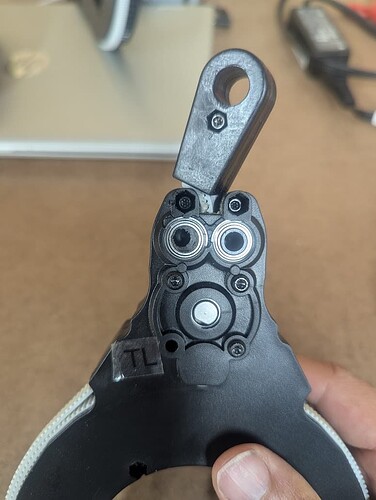

It’s three of the rollers with the magnet for the encoder.

I’ve disassembled one of the arms to begin sanding. The roller sheared right at the corner.

Since it’s one of the rollers with a magnet, I’m going to attempt to fix it by gluing the ring back on with a section of takeout chop stick in the middle as reinforcement.

What was the belt tension set to when that happened?

It’s hard to tell exactly when it happened, but probably at least 1800.

Are those ‘tails’ of the belts long enough to get between the rollers sometimes?