Hello everyone! I’ve got some big news to share.

Maslow is back! It’s been an open secret for a little while now that I’ve been working on a new and improved Maslow and the time has nearly arrived to launch it.

A quick overview Maslow4 (That’s what we’re calling it):

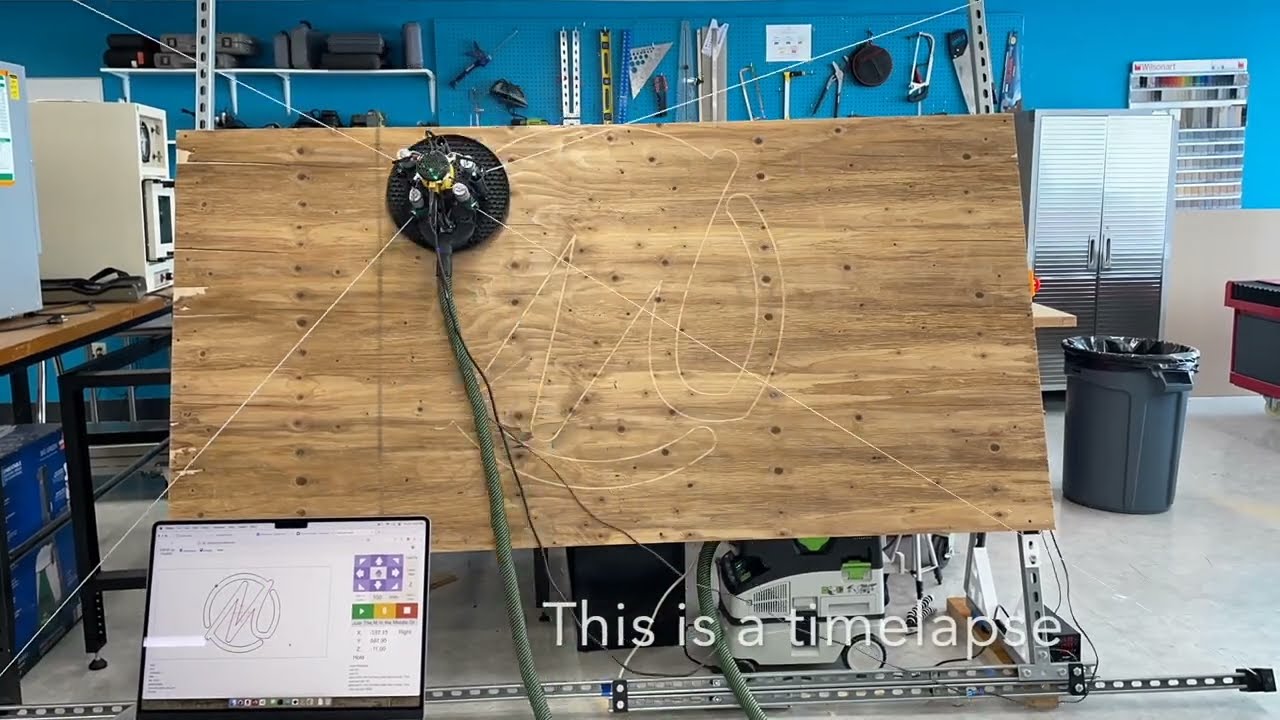

It’s a complete redesign taking the best parts of the original Maslow and all of the lessons that we learned from the original design. The two chains are replaced with four belts and all of the electronics are moved to the sled (no bricks needed ![]() ). This is all controlled with a completely redesigned five (FIVE!) axis control board with USB C, WiFi, and Bluetooth connectivity (basically it has the features that WebControl and a raspberry pi gave us built into the controller board). Four of the axis are servos with current and position feedback (so we have torque and position control) and one axis is a stepper motor for the z-axis.

). This is all controlled with a completely redesigned five (FIVE!) axis control board with USB C, WiFi, and Bluetooth connectivity (basically it has the features that WebControl and a raspberry pi gave us built into the controller board). Four of the axis are servos with current and position feedback (so we have torque and position control) and one axis is a stepper motor for the z-axis.

The new four belt system has a bunch of advantages:

- FULLY SELF CALIBRATING. We all know what a hassle calibration was. The new system is fully self calibrating. You hook up the belts with some extra slack and then the machine makes a series of pre-programed movements and measures itself. It’s accurate every time and way way way better than measuring anything by hand. Think mesh bed leveling for a 3D printer, but different. We’ll have tons of details on how this works, but it is fantastic.

- Fast. Because we aren’t limited by gravity anymore Maslow4 is way faster at 2,500 mm/min or 100ipm. That’s 250% faster than the original Maslow.

- Precise. The extra tension in the lower belts makes a HUGE difference to the cut quality at the very edges of the sheet giving us more precise cuts. Also…did I mention that it’s self calibrating?

- Compact. All of the electronics are housed on the sled now which means that Maslow4 can use any flat surface from horizontal to nearly vertical as a frame. You can use a shop floor, a work bench, your old Maslow frame, or so many other possibilities. I think that we are going to see some incredible frame designs with this one. I know I have some ideas that I want to test.

We will be doing another kickstarter campaign.

We are planning to launch a Kickstarter campaign in about 10 days on the 15th. Maslow4 kit will be $525 and include everything except the router and the frame. It is designed around the Dewalt D611 router, but we are hoping to support some other routers by the time it ships. Our target ship date is going to be November for the insider edition.

What’s the insider edition you ask?

Just like our last Kickstarter, we are going to ship kits in batches and we want to make sure that our existing community gets first dibs. We are going to post a private link to the kickstarter here in the forums and send it out to our email list before the kickstarter is public. That way our community has the first chance to get a Maslow4 before they are generally available. After two days we’ll close the insider edition tier and open batch #1 orders to the public.

Who is Roman?

You are probably wondering who Roman is? No, you weren’t? But now you are?

This is my good friend Roman. (He didn’t send me a picture so this is what I found on Google)

Roman and I met about four years ago (Geez) when I showed up uninvited to a BBQ that was held by a maker space in Kyiv, Ukraine. He is a physicist, artist, maker, and generally great guy. Because of the war he can’t leave the country, but he is helping with software development, hardware testing, and generally all the work that goes into keeping the wheels on the bus. We’ve got lots of exciting projects we’d like to do in Ukraine in the future too.

What happened to Hannah? She’s in Alaska for the summer, but we’re hoping to get her back in the fall. She says she wants to spend the winter in New Zealand, but I’m doing my best to win her back.

So that’s the news! Let me know if you have any questions. I’m around the forums and Roman is too. We’re super excited. We’ve been working on this for a long time and it feels great to be tying up loose ends and sharing it with the world.