Maslow 4 upgraded to 4.1 running 1.12

I have not been able to get the machine to finish calibrating at all yet. Currently when I have tried to calibrate and left the machine for a few minutes on of the belt motors has been slowly spooling out more and more belt, when I came back and tried to restart the process I did not realize that the belt was wound backwards on the spool. It has gotten folded and after a few more times of trying things it eventually snarled and bound up. I took apart the machine, pulled out the belts accidentally swapped the motors around and then when I tried to get the calibration process started again I saw what was happening. this time on the same motor spool in a different location. I am going to try to take it apart again and look at the magnet but I don’t think that is the issue. Frustrated that I can’t figure out how to even get the machine to get set up once. I don’t have the logs from the original bad runs. Here is the current output.

Maslow-serial.log (3.9 KB)

Error 3 is usually because you are missing entries in your maslow.yaml file or there is a version mismatch. What happens when you press test from the config menu.?

Thank you. I will try to reload the yaml. Where are the instructions for doing that? I went through all of the build instructions and manuals but could not find where the clear instructions for updating are?

Before you do that, try the test button, it will give us a clearer idea of what may be wrong.

For more information go to Maslow home (top left) then Resources. Trouble shooting Guide and Utube videos may be helpful.

go to the fluidnc tab (top left) and then you will see a folder button that

shows various files, and above that an upload button.

let me know if you have trouble finding it and I’ll send screenshots

David Lang

I would be pretty shocked if that frame is rigid enough to get accurate measurements. It’s a really cool idea, but I’m better there is some flex in the pipes ![]()

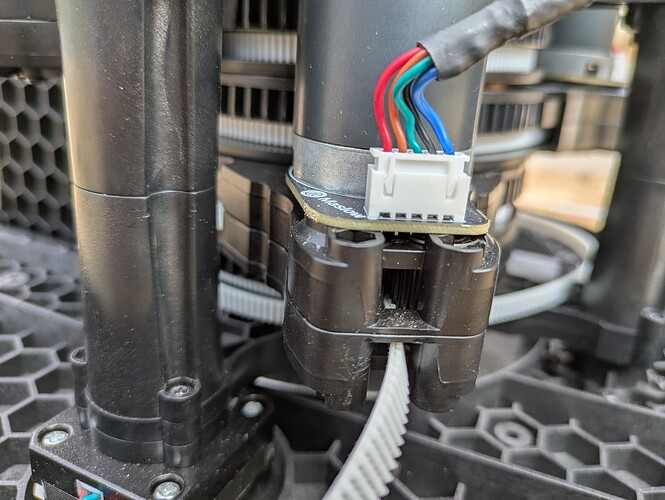

Ok, machine back together after taking apart to check the magnet. It looked really firm. I reuploaded the yaml file from the github 1.12 collection. Turned it back on, retracted, extended, retracted and then pushed test. Here is that file. I will take it out and try to run calibration again to see if the belt is still moving in and out on it’s own. Thank you for all of your help.

Maslow-serial(1).log (3.4 KB)

that file looks sane

That looks Good.

How far apart are the anchor points, diagonally. From the photo you may be approaching / exceeding the limits for belt length. To far, and it will break the spool where the belt terminates.

Maslow must be able to reach the extremes of your base board while still having some belt on the spool

ooookay new problem. Set the metal pipe frame to the side, staked the machine to the ground. Tried to run a basic calibration with a 3 by 3 grid at 400mm. didn’t work and didn’t seem like it was going to get close. Retracted, extended and then let it run calibration. Thought I would change it to a 5 by 5 grid and 600mm It found 5 points and stopped to do calculations. I stepped away for a minute while the calibration ran on the computer as that has been taking a long time and then came back to find two belts snapped at the away from machine ends and the machine trying to pull itself between the other two anchors. No idea what happened. here is the serial file. I will repair the belt ends and try again. Sigh. I just want something to work with this. I didn’t think it would try to move after it had run the calibration.

Maslow-serial (1).log (49.4 KB)

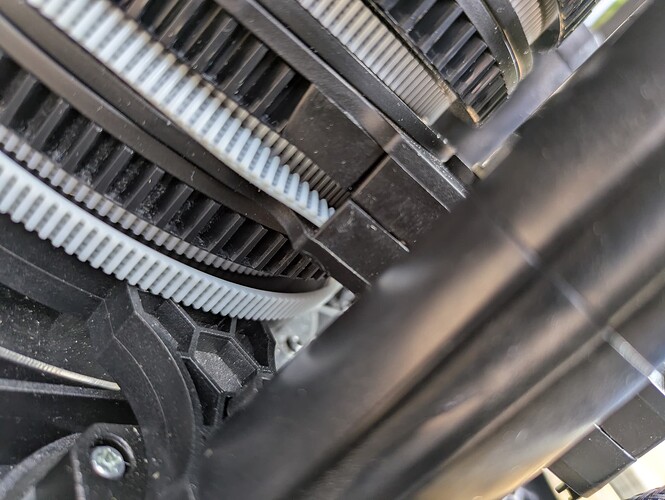

Posting here as well looks like one of the belts got turned over in the gears as it retracted and then snapped. Tearing it all down to straighten things out.

I’m fairly tech savvy and have done robotic projects before. I may be doing something stupid here but it is really not clear what. I don’t think the machine should tear itself apart from small mistakes.I don’t know that I have four hours today to take all of the spools apart and make sure the belts are straight.

Ok, pulled the belt through that had flipped over and unspooled it all the way, no idea how that happened. there is only one small fold half way and it looks vertical. the end anchor and direction look ok, so going to stick it back in and see what happens. the other one that snapped also looks ok all the way back to it’s start.

It they are about 15 feet apart. It looks ok when it is callibrating. I will check if i can ever get it past that. Thank you for the advice. Will check.

Ok. This time I watched it get through calibration? It still said it was under calibration and promptly break a belt. I have no idea what is going on. I stopped it right away before it kept trying to retract the others. Not sure what to do next. Done for today. No idea what is going on. Is there a translator page for the output on the serial?

Maslow-serial (5).log (75.9 KB)

My dimensions between the stakes were roughly 4500 by 5050mm

I see what happened from looking at the logs:

I 1000% agree. We’re very much still in the early phase of learning how this technology works and so we’re still encountering and fixing issues that are happening for the first time.

Taking a look at the log I can see what went wrong:

[MSG:WARN: Frame side lengths are outside valid range (500-5000mm). Top=3509.713mm, Right=4507.432mm, Bottom=5113.800mm, Left=2100.214mm. Correcting to reasonable defaults.]

[MSG:INFO: Anchor coordinates corrected. New values: tlX=-30.000 tlY=2100.000 trX=2950.000 trY=2100.000 blX=0.000 blY=0.000 brX=3000.000 brY=0.000]

Basically the frame is so big that the machine is going to tear itself apart by extending one of the belts so far that it can’t reach the other side. It’s recognizing that it’s too big and resizing, but that’s not the right behavior either because resizing just means it resizes to invalid anchor point locations. What we really want is for the machine to throw a warning and shut down completely because basically anything that it does at that point risks breaking something.

I’m working on a fix right now.

I think that you are doing an awesome job of pushing the limits and trying things that haven’t been tried before (and we are all getting to learn and improve as a result), but if you want to have a smoother experience it’s probably worth starting out with something closer to what has been tested by more folks

plugging your numbers in to my frame calculator at http://lang.hm/maslow/maslow4_frame.html

this is saying that you need ~4700mm of belt, which is about 15.5 ft and the maslow only comes with ~14.5 ft (and you need to leave some amount of belt on the spool, so more like 14 ft usable