Hi everyone,

I’m new to this community (as of a few months ago). I’ve followed along since the first Maslow, but didn’t feel compelled to start messing around with the Maslow until the M4 was released. I got in on pre-orders after the end of the kick-starter and got my kit in April. I figured I should share my overall first experience as your’e only new once and maybe someone else can skip a few mistakes I made.

To give you a background on myself, I’m a tinkerer and software engineer by trade and I work in the engineering and manufacturing space. I’m well versed in CAD and 3D printing and know in theory how CAM works, but have never used CAM software (unless you consider a slicer CAM software ![]() ). So here are my notes:

). So here are my notes:

Assembly

I found the assembly instructions to be very sufficient. Assembling the arms and specifically, putting the belt ends on was the hardest part for me. I ended up using some pliers to squeeze the belt ends onto the belt. A few random assembly pictures:

One other thing I had laying around that helped with assembly, was a small 3d printed thrumb screw:

I used the included allen key a few times, but I think having some sort of more efficient driver probably speeds up assembly a fair bit.

The only issue I ran into during assembly is that the linear rod supports had a space at the the bottom where they connect to the sled. I ended up losening the clamps for the linear rods and tapping more on the rods with a small hammer, but I still couldn’t get the supports to touch the sled. I ended up using a wood clamp to clamp the sled and the support so I could put the screws in:

Searching the forum, it seems I’m not the only one that has run into this problem. Either I didn’t fully seat the linear rods or something is out of spec. When placing the rods initially, I gave them a pretty good smack with a small hammer, so I’m not sure it’s that they aren’t seated. Either way, everything was bolted in place and the top two supports that bridge from the rod support to the rod have a slight bend in them.

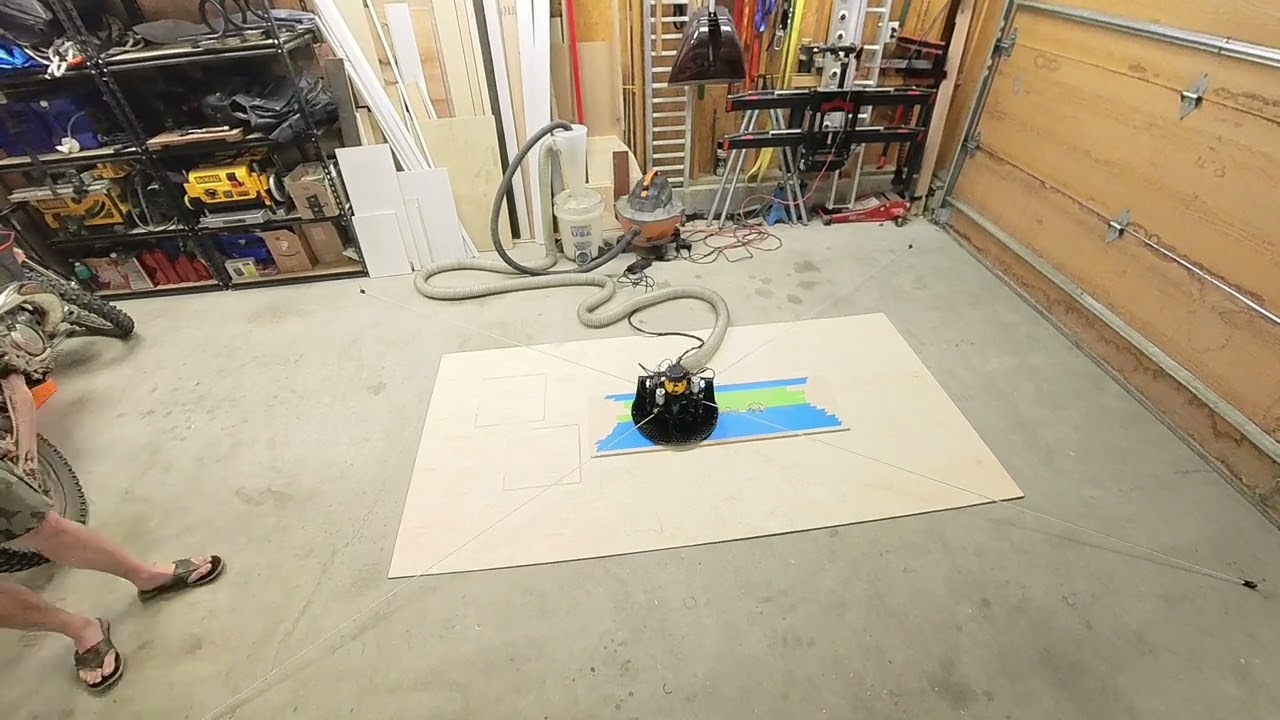

Once assembly was done I printed a dust collection shroud from repo. I also added tape around the edges to try and make the suction better. I had to cut the front two tabs off to make it fit well. I am planning to make some changes to the shroud and will share whatever I do.

Getting connected to the machine

Once I double checked everything and felt I could turn the machine on, I plugged it in and updated the firmware. Once again, the instructions are pretty clear here, although I would suggest adding a note about if a user should always update all three files updated at the same time or not? Can the yaml/html files be run with various versions of the firmware?

I have still only been using my machine in AP mode, so I can’t comment on connecting to the network.

I also read that you don’t want to let your machine go to sleep when running the machine, so I installed a Microsoft tool called Awake to prevent sleep and my screen from turning off - https://learn.microsoft.com/en-us/windows/powertoys/awake

Frame and calibration

I decided to use drop in anchors for my frame since I can pull a car out of once side of the garage as needed. I used drop in confast anchors and followed their installation video. Pretty fast and straight forward. I think I spent more timing making sure I had a nice square for my anchors than anything. My frame size is 8ftx12ft.

I updated my frame size and ran caibration without issue and my fitness was about ~.54. A few questions here:

-

Is there an explanation about fitness somwhere? What it means, what a good value is, what higher/lower fitness means for cuts, etc? I searched and dint’ find anything and would like to understand this value a bit better.

-

I assume fitness is expect goes down the larger your frame? Is my assumption wrong?

Anyway, with calibration done, it was time to cut!

First cut

Before I cut, I put an emergency stop in place that kills the router and the sled:

Man am I glad I put this in place as I would be using it 5 or 6 times in the next few hours. ![]()

First thing I had to do was find some CAM software. As mentioned above, I’m not well versed in CAM, so I had to spend some time here. I tried MakerCAM and creating some SVG files, but found that MakerCAM could not handle SVGs from Adobe Illustrator, so I made a few simple shapes in MakerCAM itself and started a cut. One mistake I made here, was I did not place the shapes at the origin in MakerCAM. This meant I had a jog in my final gcode. This made it hard to figure out where I was actually going to cut. This caused me to almost jump off the board with a spinning bit the first cut. In hindsight, I should have probably run a dry run with no router spinning the very first time. The emergency stop saved the day.

I ended up reading a bit more and settling on Easel at the moment. I like that it shows a preview and handled the shapes I was creating in Illustrator. I setup my speeds and such based on the recommended speeds thread I found. Later upped the travel speed a bit until I was getting more chips than dust and I found I was making some nice cuts.

I did run into a few bugs:

-

Units mismatch with part and UI - https://github.com/BarbourSmith/FluidNC/issues/129 - I uploaded a part in inches the the UI stays in mm. When I finished and tried to jog I found the machine was just traveling and traveling. The stop button won’t stop it here, but luckily the pause does. After toggling the UI to inches and then back to mm, I found the machine was moving 100mm again instead of 100 in. I was going to log an issue (and try to fix it), but I see it’s logged already. Once I get a dev environment setup, I’ll see if I can fix this.

-

Machine loses connectivity and becomes unresponsive. I went to lunch and came back and the machine seemed to be totally unresponsive to the UI. My computer was prevented from going to sleep, so I’m assuming maybe it lost wifi connection or something? The machine was not running and was just sitting at home until I came back, so I don’t really know what might have caused this.

-

The machine would only jog in one direction no matter what UI button I pushed. This happened a few times and I’m not sure what caused it. I was jogging around and redifining home and making different cuts and at point it would only job in the last direction and value that I jogged. Any button pushed would make it jog in say X 100mm for example. Had to restart and do the belt stuff again.

Anyway, I got cutting on some .25" ply wood and ended up cutting out 5 cat coasters that my wife is going to paint:

After playing with the machine and almost griding up a belt, almost jumping off the board, and learning the software, I feel I have a good base to move to a bigger project. I’m planning on a sign with some pocket cuts next and maybe trying out a 1/8" bit. I hope to be able to contribute some bug fixes and/or CAD designs back to the project, but I want to make sure I fully understand everything before diving in.

Thanks,

Rob