Does anyone see a problem with using a roundover edging bit similar to this with Maslow? Any suggestions or possible pitfalls? I plan to make the opendesk.cc standing desk and dont want to detatch the router base from the sled to roundover.

That will work

it’s limitations:

The stright portion will wear out before the roundover portion

You are going to be limited in how think you material can be by the bit

That material limitation is not just the max thickness, but also the min

thickness (or you are going to be cutting deep into your spoilboard)

David, thanks for the info!!

3/4 birch is what I will be using. Not saying that I will be getting this exact brand or dimension, but here it is (a bit pricey  http://www.rockler.com/rockler-roundover-edging-dimensioning-cnc-router-bit-1-in-dia-x-1-in-h-x-3-8-in-r-x-1-2-in-shank?source=googleps&sid=V9197&utm_source=GoogleBase&utm_medium=organic&utm_campaign=Google

http://www.rockler.com/rockler-roundover-edging-dimensioning-cnc-router-bit-1-in-dia-x-1-in-h-x-3-8-in-r-x-1-2-in-shank?source=googleps&sid=V9197&utm_source=GoogleBase&utm_medium=organic&utm_campaign=Google

It looks as though I will just make it through before putting a lip on the top side.

It is also possible to use a regular roundover by just removing ballbearing, just for rounding that is!

Thanks! I have a diablo roundover bit that may work… just can’t remember how the roller is attatched. Oh well, I may cut it off to test it out.

Another option, if possible, is to buy another router base and roundover after its cut out. Looks like any which way it goes I’ll be spending $40-50 extra.

Got my new 45° linkage set up, dialed in and ready! Thanks @pillageTHENburn

I had gcode set for 1/8” bit but used 1/4”. That was in the lower right corner and came out straight as could be! I also

Moved all over the board cutting PERFECT 4”X4” test squares set movement to 4.25”

I would probably cut it out normally, then just manually round off the corners personally. No need to remove the router from the base, it would just be a bit clunky. Ok, very clunky =p

I tested this at one point and it worked great!

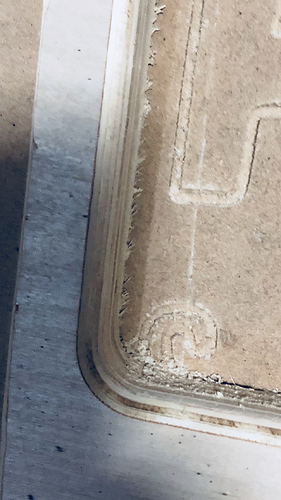

I cut the parts with a 1/4in bit first but held them in place with tabs, then went to the round over. Keep in mind that each pass is going to be more removing more wood than the last one as more of the round over engages so you might want to start conservative

Bar, as always, thank you so much!!! Was that with a roundover with a small roller or without?

I realize tabs and the lack of roundover at those points would be the issue with a dual cutting/roundover bit… Thought about doing what Ive done before; cut the inner pieces out first in the gcode, then screw the cut pieces back into the corners of the cutouts to the backer board, acting as makeshift tabs. Then would change out to the cut/ro bit for the outer edge without tabs.

I used a 1/2 inch round over on 3/4 plywood so it wouldn’t cut all the way through the tabs. It did not have the bearing, and I could have probably cut 1/2 plywood with the roundover alone instead of doing a two step process. I want to play with shaped bits a lot more as soon as I’m done with the house

Using screws could be a great solution of there are parts of the design you don’t mind having holes in.

Awesome, I have that bit!!! Ive ordered this Rockler bit today to try out,

slightly worried it may not make it through 3/4 without stepping into the top surface.Thankfully the cutout pieces are considered scrap (where legs instert) and screwed back in the same spot they came, just butted in the corners.

I’d really like to see the finished results in this forum’s Projects section. I have been eyeing Open Desk designs for months but haven’t tried them yet. I can’t wait to see how this one turns out!