We Will be son buying a maslow 4 For our shop in El salvador Central América

And would like your advice on what brand and models of routers we could purchase as well as bits For it

We would be cuting 5/8 thickness melamine,mdf and plywood

Maslow4 is specifically designed to use the DeWalt 611 router.

I’m sure we’re going to see it modified to use other routers quickly, but the DeWalt 611 is the router that we recommend.

There are issues with how the cord comes out of the router, because it can interfere with where the control board goes. From the back of the router (where the switch usually is), having the cord come out the side is better because it will not interfere with where the control board needs to go.

Honestly anything. But you will need to experiment, so be prepared to replace bits as you figure it out. I normally go for very small bit with single flutes (single cutting blade), but that’s for my old Maslow. The new one goes faster, so I have to try everything again when I get it.

Basic guide is you want it to make ‘chips’ of wood, not sawdust.

the maslow 4 moves faster, but the smaller router also spins faster, so it’s not

that much of a gain. I expect that single flute bits will still be winners.

David Lang

Preface: I’m with PreciseBits. So while I try to only post general information take everything I say with the understanding that I have a bias.

I won’t talk too much about routers as I have a very strong bias in this type towards the 611. But in general the 2 biggest “failure” points are usually brushes and bearings. Brushes are replaceable and cheap. Bearing failure is basically throwing out the router or investing in tools for bearing changes. With that said, I’d stick to a brand name that will likely use at least decent bearings that are spec’ed to the RPM and load expected.

I’m also obviously bias in tooling but can provide a lot more general information here. The biggest limit from my perspective is holding down the cutting forces. So you have a combination of trying to actually “cut” a chip and keep the cutting forces down to keep it “on path”.

The short version of this would be use a 1 or 2 flute cutter, preferably no larger than 1/8", with a high helix (flute twist), and preferably an up-cut. Why?

-

With the max feed and minimum RPM of the system you can't really support a higher flute count and still "cut". You can still remove material in the shape of the tool. But you will be grinding or rubbing it out of the way. The minimum it takes to actually "cut" material is dependent on the tool geometry and the material. Softer more flexible material will need a higher chipload (feed).

The single flute will have an addition advantage here as it’s not nearly as susceptible to runout (tool spin off the center axis of the router). Runout in multi-flute tools will cause the chipload (feed) to fluctuate across the flutes. Or if the runout is greater than the chipload, push all of the feed onto a single flute (in the case of a 2 flute cutter).

For the same tool geometry cutting forces increase for any increase in tool diameter, chipload (feed), and pass depth. As you are limited by the ability to resist cutting forces the only real reason to go larger than a 1/8" is if you need to cut deeper.

The higher the helix (flute twist) the more force is driven into the “Z”. Keep in mind though that that force is also going to be exerted on the material and that could lead to tear out. Probably the worst thing would be straight flute cutters. They engage the entire length of the flute at the same time and cause large spikes of force.

The up-cut is because that direction will try to force the Maslow through the material it’s cutting. As opposed to a down-cut where the force will be trying to lift the Maslow off the material. So the up-cut especially with a higher helix tool should provide more rigidity.

If someone wants the long version let me know. I can go more into the the force changes, chipload, runouts effect on the cut, general rule of thumb for material minimum, tool geometry, etc.

You should be able to ballpark it with chipload. Like for like any cut that would work with say a single flute tool would work at double the feed with a 2 flute. You won’t have a true like for like though due tool geometry chanes like flute rake, helix, core, etc. But it should get you close for similar geometries.

If anyone doesn’t know the simple version of chipload is the widest part of the chip taken by a single flute in a single flute rotation. So, Chipload = Feed / RPM / Number of flutes.

Hope that’s useful. Let me know if there’s something I can help with or expand on.

an expanded version would be useful

either this or the expanded version should be on the website and possibly go out

as part of a weekly update (and if you can do some video clips showing the

difference in cutting it would be great)

how deep can you go with a 1/8" bit? how about a 1/4" bit?

There’s also the fact that a smaller bit will have a lower surface speed than a

larger one for the same RPM, how does that matter at the lowest speed of these

trim routers?

how does a 1/8 vs 1/4 bit do in extracting the chips out of the cut?

and I think that it’s perfectly fine for you to post some links to the bits that

your company makes (I’m sure you make all types, so this isn’t biasing you

towards one type, and people can search for similar types elsewhere)

David Lang

Probably don’t have time to do the longer version today. I’ll post back with more later.

To your specific questions.

This will depend on the tools geometry like rake, helix, core, etc. and your failure mechanism. In this case we are almost always looking at the cutting force being the limit. The simple way to treat it is cubic material removed per flute per rotation. It’s not exact as there’s differences in peak force vs time spent under load and if the tool has a helix changes in force direction. But that’s a decent rule of thumb to work off of. If we look at it that way there a couple things we could do to even out the forces. Half the depth, feed, or stepover of the 1/4" vs the 1/8" would be the easiest (assuming the same geometry).

In general to the how deep can you go with X cutter depends on a few things. The most relevant here is cutting force. Unfortunately that changes based on the geometry of the tool. As an example the more positive rake (angle of attack) a tool has the less cutting force it takes to make the same chip. This also changes per material though as something like pine will generate less cutting forces than rosewood.

It depends on the material and tool geometry. What you are functionally worried about is surface speed. The geometry of the tool, the grade of the carbide, and the material all effect what can be used without issue to either the material being cut or the edge of the tool. So a finer edged tool (edge radius), with more rake, relief (material ground off the back), made of a higher grade carbide can handle a much higher surface speed (RPM).

In general though any decent carbide should be able to run around 600SFM in most soft materials. That works out to ~18KRPM for a 1/8" and ~9KRPM. Tools designed for these material of decent carbide will do over 1000SFM without issue.

There’s a couple parts to this. First is the helix as it acts like a pump taking the material up or down depending on up or down cut tools. So the tighter the helix the faster it moves the material up or down. The second part of it is what’s called flute volume. This is literally the amount of volume in the inside of the flute to hold chips until they are either ejected out of the tool. They both come with pluses and minuses. The higher the helix gets the “closer” the flutes are to each other and the less mass the tool has. This makes it weaker and more prone to deflection (bending). The flute volume is similar. the more material we are taking out to allow for more chips the weaker the tool gets.

I try not to ever get in a marketing or brand issues on forums. I don’t really think that it’s that useful. If there’s a good reason for it then I will if the forum owners are okay with it. But as I said in my little preface I mostly just try to help with understanding of the cutting dynamics and issues regarding cutting in general. On the selfish side, the more people know about it and how everything works the more likely I think it is that they could lean towards our tools. But I care more about getting what sometimes feels like hidden knowledge out in the open.

While we have customers with Maslows I don’t have one internally. So not something I would be capable of.

I’ll try to work up something relatively easy to follow that’s not too much of a text wall. As you might have noticed in the above, there’s a lot of “depends on”. But there’s still general rules and rules of thumb that are useful and can help with tool selection.

If anyone has specific questions let me know. Otherwise I’ll post back later with more in general to cutting and tool selection.

It doesn’t need to involve a Maslow, just a trim router showing cutting too

slow, or at too high an rpm for the bit vs proper speeds/feeds (showing the

difference in the chips/cut/etc)

David Lang

Sorry for the delay. I only get a bit of time to write in forums and we’ve been busy on top of that.

Before I get into anything elseI’m going to define a couple terms that I will be using.

Chipload:

This is the widest part of the chip being made per flute per rotation of the bit. This determines a great deal in the cut and the effects of the cut. A short incomplete list would be force, heat making it to the other components, cut quality, and tool life. To calculate tool chipload from a feed and speed: Chipload = feed / RPM / number of flutes.

Runout:

This is how much the tool spins off the center axis of the cutter (bit wobble). It’s an important factor especially in multi-flute tools as this number will get added and subtracted to chipload to various flutes of the bit.

Minimum chipload:

For every material we have a minimum chipload to actually cut. This is determined by both the material’s ability to support itself and a part of the bit that will almost never be listed called the edge radius. For most soft materials (less hard than metal) we don’t really have to worry about the edge radius except maybe for some tools that are designed for metal. If we cut less than this minimum then what will happen is instead of cutting the chip, it will push a partially formed chip out of the way or “grind” / “rub” away the material. This causes an increase in both cutting force and heat vs cutting. After the minimum we will also have chiploads that produce better cuts based on the tool and material.

Another thing to consider in chipload is that the primary source of heat (if not rubbing) is in the deformation of what becomes the chip. So the smaller the chipload the higher the heat that makes it to the material and tool. So even if we are cutting there are advantages to a larger chipload for tool life and cut quality.

Our maximum will almost always be determined by the failure point of the material, flute of the tool, or machine. These are all limited by cutting forces. In other words, when is the cutting force and direction of that force causing a failure in one of these?

Cutting force:

Cutting force is functionally determined by cubic material removed per flute. So an increase in tool diameter, stepover, cutting depth, or chipload increases our cutting forces. These are more or less proportional. Although when you include things like a helix in a tool this causes a change in the force direction which can change the when or where a failure point is.

Additional to this there are tool geometry differences that can change our cutting forces. As previously mentioned the helix (flute twist) would be one. In the case of helix the tighter the helix the more force you are redirecting to the Z axis. This can be a good thing if it gives us more room for a higher chipload where we were otherwise listed. However, it can also cause tearout of the material as we are now trying to shear it in a vertical direction.

Another thing that will affect this is the edge radius and the rake. The rake of a tool is the angle of attack. The more positive rake the less force required to take the same chip. The edge radius is the actual thickness of the edge of the tool. It’s a function of the carbide grade, grind, and geometry. The thinner it is the smaller the impact surface of the edge and the less force. Like for like, these both come at the cost of flute strength.

A few other things to cover.

Surface speed:

This is a complicated issue. The simple way to put it is that this is the rotational velocity of the edge of the tool as it spins. The larger the tool or the faster the RPM the higher the surface speed. There’s a limit based on the tool and the material where you can damage one or the other. The flip side of this is until that point you increase shear and can get a cleaner cut.

Acceleration compensation:

One thing that has to be accounted for in all of this is we can’t keep the chipload up in the entire cut. This is affected by length of the cut and direction changes. Basically we can’t go from 0-60 in zero seconds and we can’t take a 90° turn at full speed. So any changes in direction or short segments of cuts will slow down and speed up based on the machine, controller, and settings. This is something that should at least be considered when thinking about feed rates and tool selection as we want to at least be hitting minimum or as close as we can get the majority of the cut. Basically we want to be cutting above the minimum enough that we have margin for direction changes.

I’m going to stop here for now. I was planning on going over some basic ranges that could be used for these in “generic” and application specific geometry tools. I also wanted to go into some of how this could be used to compensate or trade things to make it easier to cut in force limited machines. I’ll have to try and do this later though as it’s already been way longer than I intended to post back.

Sorry again for the delay and the abridged post. I hope this is somewhat useful to someone without the missing data. Let me know if there’s something I can help with or expand on.

Thanks for this.

One thing to point out about published feeds and speeds, the numbers presented

are designed for production systems.

Where power and rigidity is not a limit.

Where the primary criteria is cutting the max amount of material in a given

amount of time before you have to change your bit.

so running a bit slower may actually be a bit better, the limit being when you

stop getting chips and start getting powder (all the talk about heat in the

chips is not something that we can see on our machines)

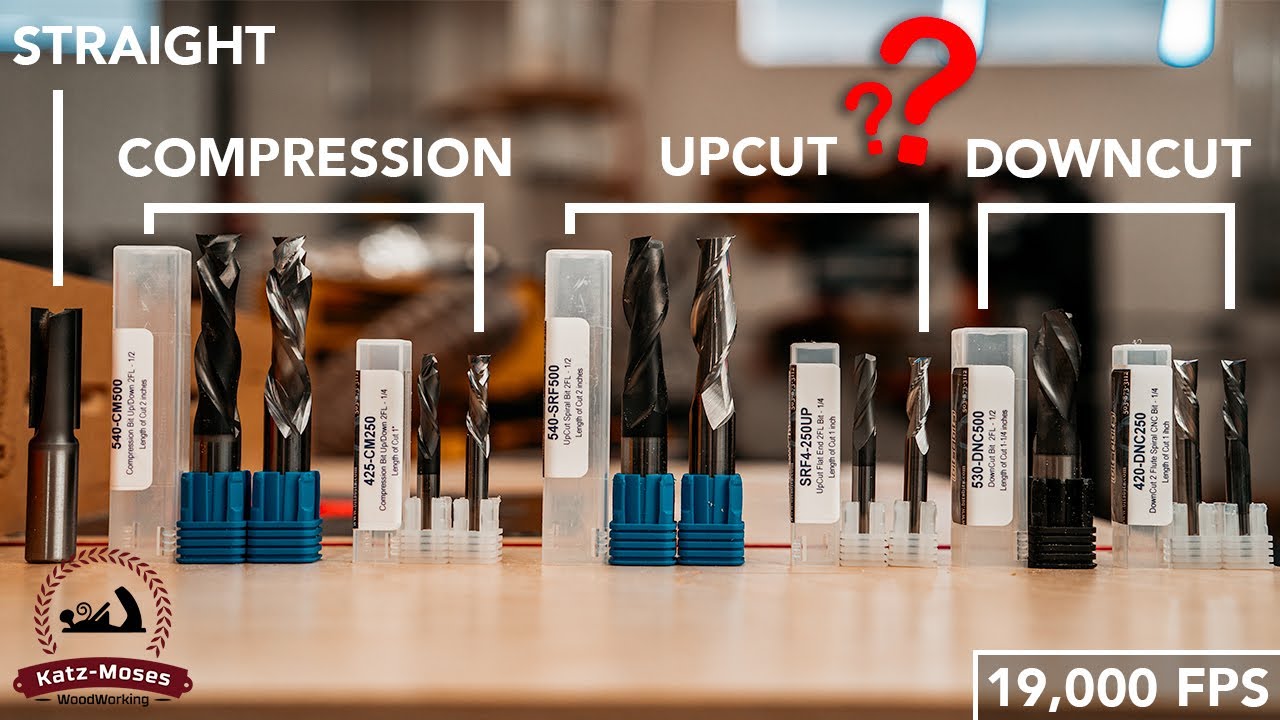

a video on different bit types

I haven’t found a good one on feeds and speeds yet

This one is fair, but focused on getting the max performance a bit much. We need

to talk about where the minimums are, with the expectation that we will

sometimes be below them with these fast routers and slow moving machines

David Lang

That’s actually only one method used. I’ve seen everything from simple formulas, to max MRR, to extremely conservative listed on feed and speed lists. The short version is that they are almost useless to at best starting points to everyone regardless of CNC used. There too many variables like runout, deflection tolerance, machine rigidity, spindle power, etc.

Gets even worse when you are talking about a variable material like wood. Closest thing you can use to scale with is Janka value. Although even that can only be used with like grain structure, like mineral content, and same moisture. Changing any of those can change the cutting parameters by substantial amounts.

To give you a rough idea, I’ve worked with production shops with 6 figure CNCs, temperature and moisture controlled storage rooms for their wood, single sources, traced batches, etc. They test everything for the actual feeds and speeds they run. This changes some for metal as it’s a much more consistent material with a lot more data behind how to cut it. But you are still at the mercy of how the tooling manufacturer came up with the data, and if a practical test what system they used and their tolerance for things like dimensional accuracy, surface finish, etc.

With some rare exceptions we don’t even list any. We have always recommended that you test for the best feed and speed for YOUR machine in YOUR material. There’s issues with this method too but I believe it’s the best of bad options. There are ways of taking decent guesses / starting points and better ones once you have some test data.

[quote=“dlang, post:10, topic:19984”]

so running a bit slower may actually be a bit better, the limit being when you

stop getting chips and start getting powder[/quote]

If you mean run slower than a lot of the charts/tables recommend then I agree. There’s not enough rigidity here to use what it typically listed by manufacturers. Although as I said I have seen some that list absurdly low numbers.

Depends on how it’s generated and where the heat is. You can definitely see it in a lot of cases of running too low of a chipload as it will leave resin on the tooling and potentially burn your wood. Temp of the chips themselves isn’t a great choice for determining a good cut though. So from that perspective you aren’t going to be able to see it due to required lower forces. But it’s not really that useful. There’s probably a way to make it useful for a specific wood, with a specific moisture content. But as soon as you add water, silica, or metals into the wood (moisture content, different species, different soil, etc.) you aren’t going to get the same values at the same place.

This was part of what I wanted to go into with one of the sections that haven’t had the time to write yet. I’ll give a simple version. In the case of the Maslow we are force limited with a stronger resistance in the Z due to the support of the platform on the wood. So let’s use a rule of thumb number for soft material of a 0.002" chipload, the Dewalt 611 RPM range of 16KRPM - 27KRPM, and say we are using a 2 flute 1/8" cutter. This will work out to a feed of 64IPM (1625mm/m) at 16KRPM. Now let’s say that we are cutting through 1/4" material. Can we cut that in a single slotted pass? Maybe, part of it depends on the material and tool. But let’s say that we can’t due to too high of cutting forces. So in this theoretical we don’t want to reduce the chipload (feed) as we are saying the 0.002" is our minimum. So the better option would be to take multiple passes at it. Depending on the tool we will lower the cutting force by about half if we take 2 1/8" passes, and reduce it by half of that if we take 4 1/16" passes. Another option would be to get rid of the slotting by adaptive or even basic pocketing to come out to your edges. This would reduce the load by ~half again if we are taking a 50% stepover.

The above could also be changed by the tool if we have a higher helix upcut as it will drive more of the force into the stronger Z direction. If we have a small enough edge radius, rake, etc. we’ll have a smaller minimum chipload. If we have a higher rake and enough flute relief we will have less force in the same cut.

Hope that makes sense.

Hello, I am one of the pre-order people so I believe I still have some time to kill before my Maslow arrives.

My question is regarding the router. The Maslow is designed around the DeWalt 611 router but since I have a Mastercraft MAXIMUM 14A 2-1/2 HP Corded I wonder if I could use this one as well. Could you please tell me what parameters of the router ( diameter, length, etc.) I have to pay attention to to check whether the Mastercraft one is compatible. One thing I read here on the forum is that the router cable can be an issue. I guess because of the PCB enclosure mounting plate.

Thanks in advance

@TDA @dlang

This was a great post. But fizzled out at the end.

Since the M4 and DeWalt 611 are known.

We should be able to get some good recommendations on bits/cutters.

Seems MDF or birch plywood seems to ge the most popular. And I would think most want to to cut the material in as little passes as possible.

I can’t afford the time or expense (nuts and wood) trying all the different possibilities.

I’d love to hear some recommendations.

Hi Geo,

I mostly left this here as it didn’t seem like there was much interest and it was leading into the M4 shipping and a lot of post with that.

There’s an issue with direct manufacturer recommendation with me as I obviously have a bias opinion and try not to get into anything marketing related.

However, the short version I can go into would be that the Maslow will be deflection limited (rigidity of the machine limits the cutting forces). So in general the most aggressive cutter the better. It’s hard to know what that is without some experience. The easiest way would be to find a manufacturer you trust and look for more application specific tools where they aren’t trying to cut everything but a specific group of similar materials (woods, plastics, etc.). Typically the more specific the more tuned it will be for a material. Up-cut will be able to out perform a down-cut or compression as it won’t be trying to lift the Maslow. 0 helix (straight flute) will have the most force and chatter/resonance as the flute goes in and out of engagement suddenly.

MDF and ply won’t produce the same forces in a cut. So while the tooling to cut them would generally be the same, there will be more forces in the ply.

Same goes for the fewest passes possible. The deeper the pass at the same chipload (feed), RPM, stepover, and tool the higher the forces. In deflection limited machining that means that you could be left with the choice of either starving the tool and getting worse finish and tool life, or taking more passes.

Hope that’s marginally useful. If there’s something specific you want to know, or that I can help with in general let me know.

Realize this is an old post but appreciate all the science and experience youve brought to the table.

Have you used the new Maslow yet? Thoughts or recommendations on bits, feeds etc?

Thanks!

No problem.

I personally have only been in the same room with one a handful of times (one of our customers). We sell to a number of users though. And the physics of deflection limited machining doesn’t change.

To me it functionally stays the same as the rest of my posts in this thread.

Functionally the least “springy” axis you have is the Z and it’s strongest resisting the tool trying to pull it down. That would mean an up-cut. The tighter the twist on that up-cut the more force is transferred to that direction (higher chance of chip/tear out though).

Aggressive tooling causes less force for the same cut. So I would look for application specific tooling for soft media/woods/plastic and not a “can be used with every material” tool.

There’s minimum chipload (feed) that you need to hit to cut and not rub or grind (using the endmill as sandpaper). The higher your feed though the more cutting force you are trying to resist. That pretty much leaves multi-pass cutting as the best solution to hit a cutting feed and keep deflection down. Alternatively, if you are slotting moving to a smaller diameter tool will also lower your cutting forces. That comes with other caveats though.

What the minimum chipload is depends on the material and tooling. A general rule of thumb number for domestic hardwoods is 0.002" (0.051mm) for tooling around 0.0625" and larger. To work that into a feed you need RPM and flute count (Feed = chipload * flutes * RPM).

Hope that’s at least a little useful. Let me know if there’s something I can help with.

I purchased a single flute up cut bit per your commendation and you gave me the confidence to run faster instead of snails pace and too fast of a router speed. Previously was at 30 ipm and #4 speed on the router.

90 ipm at #1 gave great results.

New Bit

Old bit was a 2 flute design I had lying around. Freud 75102 2 flute sprial up bit. https://www.amazon.com/Dia-Up-Spiral-Bit-Multi/dp/B00004T7JZ?th=1

Here’s pictures of the various cuts - Ignore the tab remnants as those are purposeful and easily removed with a round over bit with the router table. I took pictures of the worst area for each cut.

2 Flute - 30 ipm - Router Speed 4

2 Flute - 60 ipm - Router Speed 4

1 Flute Up Cut - 60 ipm - Router Speed 1

1 Flute Up Cut - 90 ipm - Router Speed 1

Thanks so much for these very helpful tips. One other question if you dont mind. Do you recommend conventional or climb cutting direction?

I think questions on bits and feed rates comes up a lot for everyone. I decided to make a list to consolidate individual user’s experience and opinions. The list is on a google spreadsheet and any one can click the “ADD BIT” button which links to a google form and the form spits all the responses back into the list on the google sheet. The form is used so that responses can stay reasonably consistent and allow people to make better apple to apple comparisons.

Please feel free to add any bits and rates that you’ve used and your experiences. Also, let me know any changes needed to spreadsheet or form.

Here’s a link to the spreadsheet: Maslow Bits and Feed Rates Spreadsheet.

Sorry for the delay. Got unexpectedly busy with a short deadline project.

That’s an interesting cutter. Guessing it’s intended as an aluminum cutter from the helix for a single flute. Glad it’s working well for you.

Depends on what you are trying to achieve and the material being cut. Best finish will switch around between soft materials and tooling. Dimensional accuracy will typically favor climb cutting. Cutting force peaks and means shift (feed vs transverse). Keep in mind when slotting you are always climb and convectional cutting though. Best you get is picking the side you are keeping.

All of that basically comes down to what the flute is doing in each of those cuts. In conventional your chip is starting on the shallow end of the chip and getting bigger as it forms. This means that it’s going to be pulled “in” (deflect) to that side and forces go from low to high. In climb milling the flute starts the cut at the wide side of the chip, gets “pushed” (deflected) away from the climb side, and forces go from high to low. Just to cover it now, I’m talking above about the transverse direction (perpendicular to the feed). In the feed forces are flipped.

Different materials and geometries react differently to those. So “recommended” depends on which factors are most/least important, the material being cut, and the tool geometry.

I doubt it… but hopefully that’s useful. Let me know if there’s something I can help with.

I very much appreciate the response. So far conventional seems to work well enough but understand how climbing would yield to better accuracy. Appreciate the detail.

I had troubles finding a single flute bit that and that one was available. Seems to work well though in case anyone else was looking for recommended bits.