I did this real quick so make sure you look it over.

Cubs Marquee Latest.zip (23.4 KB)

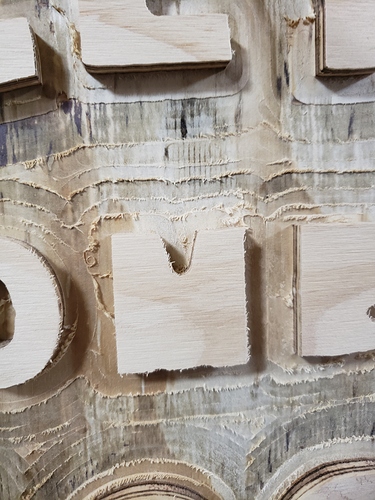

Thank you very much. I’m still cutting the original i started with. I have 15 hours into it. Lol then it stopped and said usb lost connection and wanted me to recalibrate machine. Again i just hit home and cleared gcode and reentered it and seems to be cutting in same path. Wow what a learning experience. Still trying to figure out how to clean up letters. I’m thinking just make a gcode for each letter that needs work with 1/8 bit i guess.

As far as I’ve gotten so far. If i cut another one, i don’t think I’ll go as deep. Takes a long time to make 3 or 4 passes around it. Lol

When it said it lost USB connection it was on the start of the Cubs win area. So i just made a gcode of that area and just running that. Then when done I’m gonna make another gcode to cut it out with tabs. Hope that’s the right way of doing it. Lol newbie issues!!

Wow that is looking really good. I like the look of the deep cut. I think I only did .15 or .1. I like the shadows the deep cut makes!

Wait til the sanding and painting. That will take another 15 hours🤣

I cut it to .375 and the Cubs win to .5 i ran some of it at .1 but now bumped it up to .2 and speed of 20. Seems to be cutting ok at that ratio. I see there’s gonna be a lot of sanding!  not looking forward to that at all. But gotta do it!

not looking forward to that at all. But gotta do it!

it seems to cut cleaner at .2 and 20.

it seems to cut cleaner at .2 and 20.

I’m gonna make a very shallow pass over top part again i think to clean it up more so less sanding.

That line through cubs, is that where it lost connection

No. That was just a spot in plywood. Like the top piece had a crack in it when they glued it all together. Best sheet they had at menards. Lol I’m just gonna wood filler it. Should of seen the rest of them. Horrible wood at our menards here. Should of seen me trying to get straight 2 by’s for the frame. Omg garbage. I wound up getting treated for most of frame because they were straighter.

Wow. Not sure what happened here. But that pretty much ruined this sign! Ugh it’s not like that in gc. 17 hours down the tubes.

Did it cut the back end of the C off? Could router that c flat and cut another C out of 3/8 or 1/2 plywood and glue it in?

May need to do just a chain calibration since you lost connection at one point. Chain calibration is different then Calibration you did in the beginning.

Yup sure did! Cut everything else perfect and cut that at a weird angle and didn’t cut the extra beside it.

It’s complete. It paused itself and asked me to do a tool change. It did it about half way through also. That normal?

Looks great! Unfortunate about the C but that can be fixed. If you have a 1/8 bit you could do a profile around the M to get the corners. Same thing with the connected spots in the G’s. Yeah, if you use different size bits it will pause to do a fool change.

Haha, I assume you mean a tool change. Err, I hope you mean a tool change. ![]()