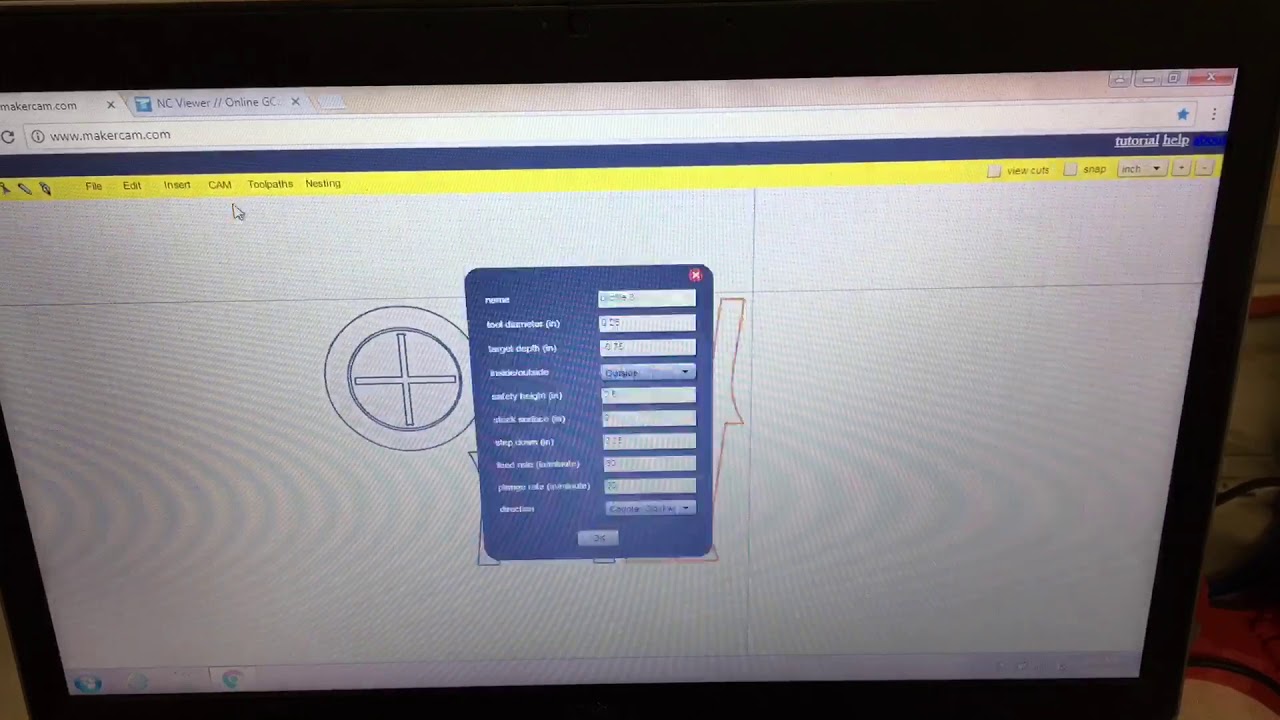

We cut a chair, a Maslow CNC logo, and now a bar stool! Having alot of fun and still planning on some more upgrades. Wanted to share this fast paced video of makercam, ground control, maslow cutting, and tapping together the parts to complete a stool for our new community workshop ![]()

Oh man that is amazing!!! I love watching something go through the entire process so quickly. Great video!

Love me some shop stool! Over on another forum, a bunch of us did a crowd-build in honor of Jimmy DiResta’s contribution. Here’s my entry.

Well done!

Thank you

Thanks for sharing, I like your design even better, will have to try that next. It would be my first attempt to export gcode from easel, and import into ground control.

Sweet! There was a note from another forum member that suggested the slot tolerances may be a bit off, or they used a different thickness of sheet good. Not sure. Just be careful. This project was also an exercise in drawing something up in SketchUp, exporting to DXF/CAD, then generating the Easel file. Fun stuff…

I can’t wait to get mine out together.

One noticeable thing in the video is just how much the original frame design flexes. Watch the upper right motor arm doing the safety dance. It’s remarkable how the time lapse really accentuates it.

Someone should do a similar video with the new frame for comparison.

great vid, and build, it shows how much flex there is in your frame and still get great fitting parts

nicely done! I would love this chair to be my fist cutting project, is there any way you can upload all the files needed to make this?

Did any of design files for this stool get uploaded so I can make one too?

Not that exact design, as far a I can tell, but a Maslow version of it is in the Community Garden along with a few other shop stool designs.

Edit: just realized that the question was asked six years ago. Well, at least you got an answer.