Yep got it’s ok I’ll wait till you send whole package with 3D printer bracket.

Funny, from just a casual reading I’ve seen several recent mentions in this thread that is indeed for sale.

So this month, right now, when you asked, YES it’s for sale.

Last month, once I saw that the site was live, I bought one. It arrived in a week. Nice kit BTW!

Metalmaslow. Quick question. I have the original maslow and made my own unistrut frame. Do you have any pics of your frame. I would like to see how the two laser cut motor mount top bars you have for sale on your website mount. I am going to order the z axis upgrade kit and am thinking of ordering the top bars also.

Oh and if I order z axis upgrade kit, does it come with a router clamp?

z axis upgrade comes with 3 5/8" clamp for Ridgid R22002 router by default, but if you are using a smaller router you can email us to use a 65mm Makita or 71mm dewalt bracket. or 3d print a round reducer shim.

you can also buy router clamps from www.bulkman3d.com but they need to be shaved down about 1/8" using a carbide blade meant to cut aluminum

Current kits come with wooden screws, but we will be switching to the Bar’s Bolt through design because it is faster to build and easier to swap out wooden pieces if ever needed ( hard to do that with glued together frame)

Our frame is actually metal, not wood, but if you look at the bolt through design you can see there are just two bolts that hold the top bar to the frame. that is how it would attach.

Our goal is to have a few maslow machines set up when the steel cross bars come in to test how repeatable calibration is regardless if one uses a metal or wood frame.

Order placed. Thank you very much. Are there any special calibration settings that I need to use with the new z axis kit?

The z axis on the upgraded metal sled has a lead of 8mm. The default is about 3, so the upgrade is about 3x faster, one can buy differnet pullies on top to make it even faster if wanted.

4 x times 3.17 mm = 12.68mm. I dare to doubt that this is recommended.

Wow, that lead and pitch on the screw would interest me and the gear ratio please…

If ‘gears’ are involved the answer could be correct, i do admit.

The easy way to be sure:

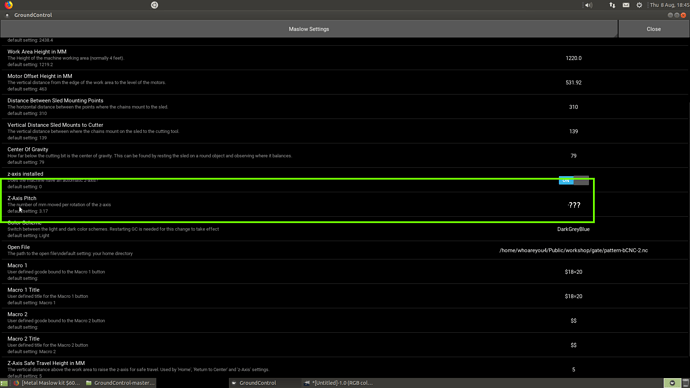

If you make a thin mark on the coupler or gear (Z-motor side), in line with a reference point on the Z-motor mount, and use the z-menu to turn the Z-motor ~exactly 1 round, with a callipers measure the mm Z moved, you can set the exact movement in GC clicking on ‘Settings’

and adjust the value you measured right here and you are good to run.

If Z turns the opposite direction, add or remove a minus { - }.

I prefer the route of editing it with a txt editor in the groundcontrol.ini found in your {user folder on top level}, with GC closed. The value name is

zdistperrot = ???

Kind regards, Gero

I’d love your recommendations: What is the best frame to build to use with the metal maslow and metal top rail?

If it’s a c-beam, the lead screw is a 4 start 2mm pitch 8mm diameter acme screw. So, if it uses the same size gear pulley for both the motor and the c-beam, you would want to use 4*2=8mm pitch in ground control. (really the label in ground control should be “lead”, not “pitch”)

Increasing the Z speed with the $18 command came with a warning that it could influence the x/y/z coordination. Increasing was giving me accurate z-feed rates (g-code), but never tested in real cuts on the effects.

Do you have a opinion on that?

![]()

![]()

Edit: 4 threads on a 2mm pitch screw will give 8mm lead (movement), 2 threads will give 4mm and 1 will give 2mm.

the lead is 8mm, just measured it to make sure.

I’m only partially following (especially the term pitch for the turning of the rotor?) but I’m seeing the problem with the z-axis not moving the correct amount on my metal maslow. Should I change the 3.17mm value to 8mm to fix this?

And THANKS to all you big brains out there making this work!

The bigger gantry plates came in from China last Friday and we spent the weekend putting them together

They are much more sturdy and it’s easy to adjust the rollers

for those of you who ordered kits using the Rigid router A few went out today and the rest will go out tomorrow

Sweet… then I can start putting mine together, finally.

I may have already asked this but do you plan to sell just the z-axis upgrade?

if all you want is the c beam , you can buy it and the xlarge gantry plate from www.bulkman3d.com and 3d print a router holder. They also sell spindle holders, but none of them are big enough to fit the 92mm rigid R2202

https://bulkman3d.com/product/pl0020/

we do sell a laser cut sled, with 45 degree linkage kit, c beam and router bracket for

$120. Mostly for people that do not want to make their own “meticulous z axis upgrade”

The terms “pitch” and “lead” can be confusing. Pitch is the distance between threads on the screw. Lead is the distance the nut (and hence the router) moves with one full rotation of the screw. The two values are related by the number of starts. If you look at the end of the screw, you should be able to see the number of threads that start at that end.

This post (Don't understand number I needed to calibrate my Z axis) might help you visualize the difference.