So I am trying to figure out why my z-axis keeps moving the wrong amount - it seems that when I put in 1 mm (I have a 8mm lead screw - from the Another Z-Axis 3D print instructions) and the unit moves 5 mm. I run the motor test and my motors are not reporting back happy - they both move but then both say fail on direction. (The sled motors are also reporting as fail on first move but ok on 2nd?). Any thoughts or ideas?

Here is a post to the formula to calculate your z axis plunge.

I think I just need a new z-axis encoder… going to try that next. Currently the z-axis just goes so far because of time… it does not seem to move based on where it is at all… it currently goes about 5mm each move

The new z-axis motor solved my problem… now I just need to get the right tension on my chain pulleys. Any suggestions on a proper weight?

Bradley Miller wrote:

The new z-axis motor solved my problem… now I just need to get the right tension on my chain pulleys. Any suggestions on a proper weight?

The key is to not have enough counter-weight that there is more force on the

non-sled side of the sprocket (there is backlash in the gearbox, you want to

keep the net forces always towards the sled side). somewhere in the 4-7 pound

range is typical, but it will depend on exactly how heavy your sled is.

David Lang

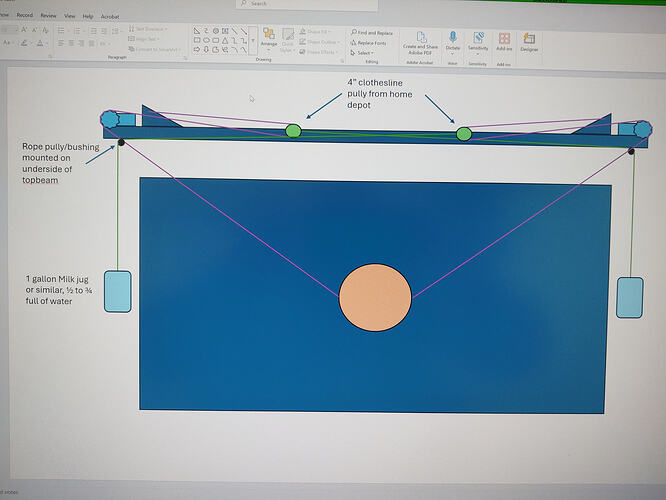

I suggest abandoning the bungies and going with weights, like milk jugs filled about half full with water.

Could you give me a better diagram of what you are doing there? That looks very intriguing. My weights just hang down, but this looks better to engage the chain/sprockets?

Hope these diagrams help explain it better

instead of the bushings at the sides, you can get a sweep like

https://www.homedepot.com/p/Cantex-3-4-in-90-Degree-Bell-End-Elbow-R5233824/202043345

and run the rope to the weight through it.

David Lang