I re-ran my calibration for a horizontal setup to see if the machine would calibrate more closely the 2nd time. My machine calibrated on a 9x9 grid with a final fitness of 0.9245873289374754

The final calibrated measurements were

- Maslow_tlX: -11.6

- Maslow_tlY: 2430.9

- Maslow_trX: 3647.2

- Maslow_trY: 2416.9

- Maslow_blX: 0.0

- Maslow_blY: 0.0

- Maslow_brX: 3641.8

- Maslow_brY: 0.0

When I measured by hand, I ended up with the following

- Bottom (bl-br): 143.125"

- Top (tl-tr): 143.875"

- Left (bl-tl): 96.375"

- Right (br-tr): 95.875"

- Diagonal (bl-tr): 172.375"

- Diagonal (br-tl): 173.0625"

which matches the following coordinates

- bl: (0, 0) mm

- br: (3635.38, 0) mm

- tl: (34.06, 2436.62) mm

- tr: (3657.31, 2447.15) mm

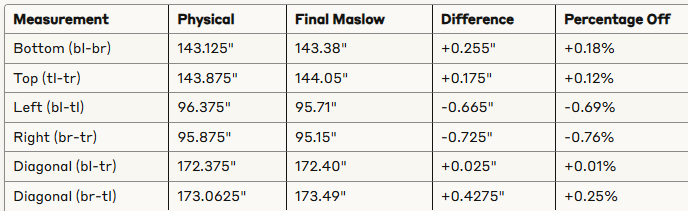

The calibrated measurements are off from the hand measurements by the following

The calibrated frame size is squished in the y direction and just a hair wide in the x direction.

I wanted to test this by cutting some shapes using the calibrated measurements. When cutting a 9" square (using Krabzcam Profile Outside), I ended up with a rectangle that is 9" tall by 9-1/32" wide. This is oversized in x by 0.346% and spot on in the y. I would have expected a different result based on the comparison of the physical measurement to the calibrated. If the calibrated frame is shorter in y than the physical frame, I would expect everything to cut larger in that dimension. Am I off in this assumption?

I also tried cutting circles to see how they came out. I cut 2 pockets (1 @ 3/4" diameter and 1 @ 2" diameter). The 3/4" diameter looks terrible. It is correct in width but short in height by almost a 1/16" The 2" diameter is similar in being correct in width but off in height by about 1/16"

I cut a 6" diameter circle using a profile inside. It is off in both height and width. Both are small. The width is close, but the height is off by about 3/32"

I also cut a 9" diameter circle using profile outside. As the best I could tell is the height is off by 1/16".

When I look at the cut quality of the square vs the circles. The arc’ed cuts are smooth while the straight cuts are not. The straight cuts seem to wobble in and out by about 1/64", which could also be affecting my measurements. NOTE: I have used paste wax twice on the sled and these test cuts were in melamine which is very smooth. I don’t think that friction was an issue in the wobbliness of the straight cuts.

I am a little lost on how best to proceed with the machine. None of this is a simple scaling, since the circle cuts and the square cuts are scaled differently. Some of my issues could come from the bit not being sized precisely. I was assuming a 0.250" diameter bit, where is seems to measure at 0.246". However, this should affect each cut by 0.002" combining that error to the full 0.004" (~ 1/256") when measuring a rectangle or circle.

On a previous calibration, I had noticed when I cut a full sheet of plywood, my y dimensions towards the edges of the plywood were off by 3/32" for a 23" cut (which is an error of 0.41%). I redid the calibration because I wanted to see if I would get a more accurate cut if I set the z-offset to the thickness of the spoilboard (7/16").

I could try hand entering my measurements and see how they come out.