did anyone ever try the 25T sprockets? how about something less drastic like 16T sprockets?

A ‘blind’ one person opinion:

As long as the ‘sled is not keeping up’ is continuing to keep up, speed increase should be set further back on the ‘non existent road-map’.

I have done nothing with them, I have them sitting in their packaging still and have not even taken them out because of time and as of now it is doing what I want and I do not see the necessity. However, that can always change.

I agree with this, and in addition, given that we now know that we are near the

limits of the motors in the top center, increasing speed and decresing torque by

2.5x is going to mean that the motors cannot get you to the top center.

we would need to figure a way to decrease the sled weight (possibly by tipping

the frame closer to vertical) and possibly make some other tweaks to get the max

force down (see the spreadsheet to play with details)

David Lang

the motors can get to the top center if the top distance Is increased to 30" and/or tilt is decreased as mentioned. I think I will order some larger sprockets and at least try it to give real world feedback. Probably 16T, I think 25T is pushing ones luck! I thought 2 years after release at least one person would of tried it, but I guess not.

Certain materials like foam can be easily cut at higher speeds and many projects do not require very high precision. While larger sprockets might not be the best choice for hardwood, there are other materials where they would probably be a benefit!

16 tooth gears can be made to work, but 25 tooth gears won’t unless you go to a

lighter sled

increasing the motor height to 30" with a 10’ top beam still requires 21.77

pounds of force to hold the sled in the top center, which is the equivalent of

54.4 pounds of force with a stock sprocket. We know that a heavy sled that

requires ~50 pounds of force in the top center cannot keep up.

David Lang

can you explain more how 21.7 lbs force is equivalent to 54.4 lbs of force?

if no one has tried bigger sprockets has any one tried faster motors?

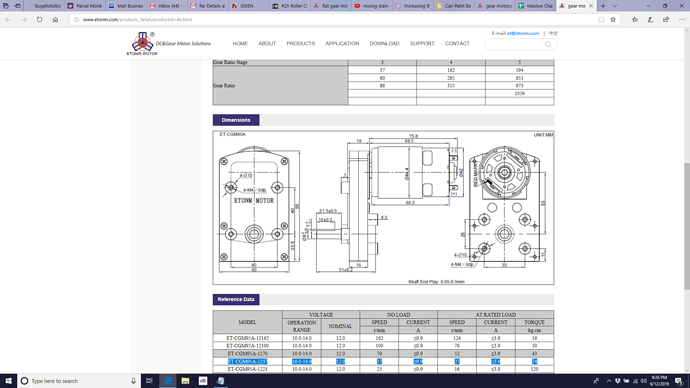

http://www.etonm.com/products_detail/productId=46.html

would this motor work? it has 74kgcm torque vs 50kgcm torque of stock motors and a faster speed of 27rpm vs 20rpm. 35% increase in speed sounds reasonable. I dont’ ever expect this machine to be 250% faster than it was initially but I do think there is modest room for improvements.

I was referring to the effect of the 25 tooth pully, 2.5x circumference, so 2.5x

diameter. So it would multiply the load on the motor by 2.5x

a 16 tooth sprocket would only be 1.6x as you describe.

David Lang

that looks like it would be an improvement (although note that it draws 4A, the

stock motor shields support 2A and the smoke herder shields support 3A), but it

does not have an encoder, so you would need to add one.

something like this on the output shaft would work well

https://www.digikey.com/products/en?mpart=AMT112Q-V-2048&v=102

(it even has an index pulse that could be used for finding the 12 o’clock

position automatically)

Make your motor controller support 24v and you will have much more power and

speed, probably able to support the 25 tooth sprockets. giving you a much higher

top speed.

note that the usability of that top speed may be limited until we have

acceleration planning in the firmware.

David Lang

are you sure TLE5206 (smoke hearder) only supports 3a?

http://maslowcommunitygarden.org/TLE5206-PowerControl-Boards.html

above page says 5A per motor supported.

etonm makes an encoder for this higher power gear motor

http://www.etonm.com/products_detail/productId=95.html.

Making a 24v motor controller shield is beyond my knowledge unfortunately. I wonder if the TLE5206 would need to use thicker copper traces to support the 3.9a per motor, total of 8a, that is a decent amount of current at full load, though I do not know if the maslow would put it into full load very often.

etonm makes an encoder for this higher power gear motor

ET-MY42-dc gear motor manufacturer/Etonm Motor Co., Limited.

that can work, but in some ways, an encoder on the output shaft is better. pick

based on price.

Making a 24v motor controller shield is beyond my knowledge unfortunately. I

wonder if the TLE5206 would need to use thicker copper traces to support the

3.9a per motor, total of 8a, that is a decent amount of current at full load,

though I do not know if the maslow would put it into full load very often.

you are right that the TLE5206 is able to support up to 5A, so it depends on the

traces.

The TLE5206 is also able to go up to 40v, so 24v should not be a problem, we

would just need to have someone check that the 5v regulator on the board (that

feeds the encoders and the arduino) is able to handle 24v (odds are very good

that it can)

David Lang

by the way, what do these motors run, and where can you buy them in single-unit

quantities?

David Lang

I have looked through etomn’s website and do not see a more powerfull 24V motor. Is there a specific one you suggest? Actually I was surprised to find the one mentioned a few posts back, because I have looked for more powerful motors on the website before without any luck.

I think I will try the 27rpm 4a 74kgcm motor first and if it works, then I can push my luck with bigger sprockets and if that works, I might try 24V motors.

I will email them for costs. I doubt they will sell them individually, but might sell a test batch.

I have looked through etomn’s website and do not see a more powerfull 24V motor. Is there a specific one you suggest?

That page you linked to for the motor says it supports up to 24v.

There are a lot of motors available on Amazon, the motors very similar to the

maslow stock ones are also available in 24v versions.

Actually I was surprised to find the one mentioned a few posts back, because

I have looked for more powerful motors on the website before without any luck.

I think I will try the 27rpm 4a 74kgcm motor first and if it works, then I can push my luck with bigger sprockets and if that works, I might try 24V motors.I will email them for costs. I doubt they will sell them individually, but might sell a test batch.

the problem with the stock motors was that the minimum order quantity was 1000

David Lang

Maybe 1000 minimum order was true a few years ago, but I have corresponded with them and that is not the current situation. I will let you know once I hear back from them. I’ll mail you a couple if you want to try them out.

Yes I know they come in 24v versions, but I have no circuit designing skills and getting someone else to design a custom circuit for you is expensive.

they quoted me about $220 for six sample motors with shipping included ($80) Not sure why they can’t ship them eparcel/packet for $2 like every other Chinese seller does, lol. . However I am skeptical about getting them since it appears they do not use a worm gear and thus the gears might slip when the power is turned off is my understanding?

David, could that be rephrased to: " given that we now know that we are near the

limits of the ‘standard’ motor shield and ‘standard’ power supply’ in the top center " ?

Going back to the first post, @MeticulousMaynard was on FW 0.94 or 0.95 on that date is a guess.

A lot has changed since then.

Strongly trusting Davids numbers that X/Y motors can do ~ 48 inch/min ~ 1219.2 mm/min.

With a TLE shield and equalized power supply it was not tested yet (to my knowledge) to edit the Settings.cpp line 80 (FW v 1.26) before uploading the FW and changing the feed-rate in GC as well.

@aluminumwelder, do you have a TLE? Just thought it would be worth a test going near 1200mm/min before spending money. Other then the to high number of “Sled not keeping up” reports, i would also expect that missing acceleration/deceleration could start kicking in. Sadly not ported back from the Due branch (perhaps the Mega limits).

Programmers:

A grep on ‘maxFeed’ is sending mixed signals (700 vs. 900), only in the comments i guess.

Make up your mind ![]()

Just in case i went off-topic, sorry, can’t help it sometimes.

Kind regards, Gero

Sorry guys, just catching up now.

I do have my own set of 25T sprockets that I bought way back when, but I never got the chance to test them out. It’s been on my to-do list now for awhile, but it’s been a long time since I’ve been able to do any testing on my machine. Right now, it’s down with a busted Z-axis (the original Rigid router base) and I really need to upgrade it to incorporate my own Z-axis design.

Unfortunately, though, house projects have eaten up a huge portion of my time. I probably won’t be able to get back to working on my machine until the fall/winter.

I’m definitely going to keep an eye on this space, though. Seems like you guys are heading down the right path. I’ve thought as well about going to more powerful motors, especially if the new sprockets don’t give me the results I’m looking for.