Since there’s some interest, I’ll post a couple of things I learned along the way on the picnic table project:

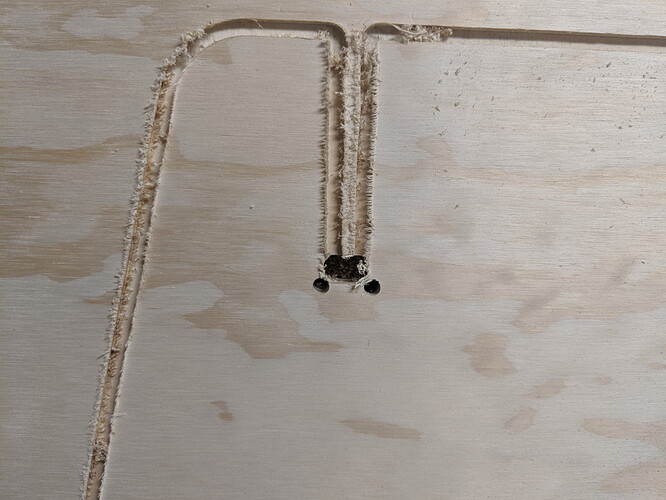

First of all, I’ll say I am still surprised at how accurate I was able to get my machine after some fine tuning. However, I had to do a little work to get the slots to cut and fit nicely over such a large piece. Here’s my trick, I call them mouse ears: At the end of a slot I pre-drilled the corners then milled out the bottom 1cm of the slot. I found this helped the machine cut the final outlines and take the corners without too much of a slowdown and also not get deflected by the sudden change in load direction for a 90 degree corner. It was the right compromise between deflection caused by changes in speed and deflection caused by changes in load. At least, this is how I did it, and it worked well.