Thanks!

Okay, I just checked 25 out of 100 from my most recent batch of hardware and every single one fit perfectly. While not definitive I think those are pretty good odds. If you message me your address I’ll send you two new pins that are personally verified to fit! ![]()

(That goes for anyone else who has a linkage kit as well, if it’s not right I’ll make it right!)

-Logan

Seen a project over at Inventables that I wanted to put a spin on for the wife for Christmas decor. Not finished but she loves it and here it is so far.

The second thing I carved with my Maslow. Excited to cut more.

Was putting together an album and thought i might as well share it. Year One with Maslow, so not really what i cut today but anyway…

Wow that looks fantastic! I love the color choices!

Thanks

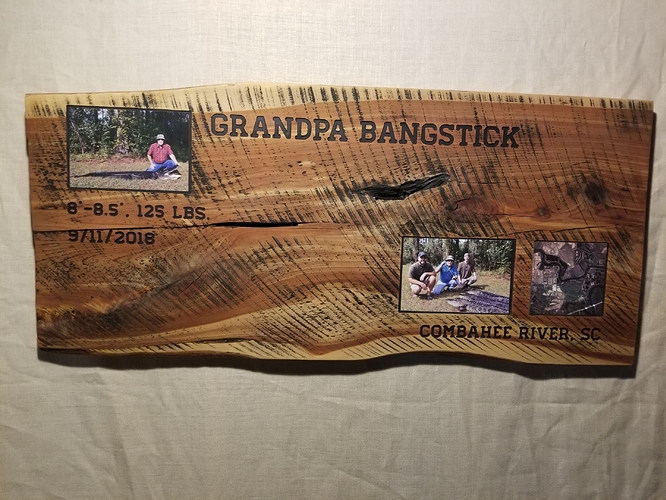

Did some projects for Christmas presents. Two signs, one of which is the logo for one of our buddy’s dad’s music act.

I was going to use it to make 1" thick maple cheeseboards in the shape of a lake we own a picnic lot on, but 3 of 5 passes through the 3d printed bracket on our new C-beam z axis detonated itself, so I had to abandon the plan and make them with a bandsaw not as cleanly.

!What kind of plastic were you using for the 3d printed mount? Is the model available somewhere?

How spectacularly/dangerously did it fail?

Wow… that had to be a lot of force on the router bit. What feedrate/bit size/depth per pass were you running?

I was assigned the task of making presents for four local family friends and my mom. Repeatability is a nice feature of maslow. I need to let the paint dry on the left three then shoot a final coat of shellac over them. Nothing like “cutting” it close :)

I’m not sure what kind, one of the other co-owners is the 3d printing guy. He is going to rotate the layers 90 degrees so the torque acts on it differently, and also infill more layers so they are more solid and less honeycomb. I’m sure it’s more complicated than that but that’s how I understood it. Not sure what you mean about the model, the computer file for it?

It gave a crack and started gouging out one side of the design, just kind of bumping around over there. There were wisps of smoke but that is fairly common with maple in my experience, but the router was still sitting on the c beam so it didn’t launch itself or anything like that.

I’ll check but I’m pretty sure it was 30, 1/4", and .125" passes. I think the bigger problem was just the weak lower bracket design but in hindsight I could’ve taken even lighter passes since it’s hardwood not plywood.

Would you mind asking what type of plastic he used (PLA vs ABS vs PETG vs Nylon)? I assume PLA from the look of the break. I wonder if PETG would be better.

Yeah the computer file for the model would be much appreciated. Not sure how it was modeled, but closest to the original would be nice so I could potentially iterate on it.