Update Oct/Nov 2020 : New thread here:

tl;dr: I’ve been working with @MakerMadeCNC and @Metalmaslow to create a single app that can support all different versions of Maslow. I’m looking for beta testers before pushing it out to the whole community.

Some time back, we discussed the possibility of using CNCjs to replace WebControl once the M2 was released. To centralize efforts, the goal is to have all the different Maslows use this one piece of well-designed software (cc @Orob, @madgrizzle ) . However, the maintainer of CNCjs is indisposed, and the MakerMade folks have created fork of CNCjs called “Makerverse” with his blessing.

Hardware Setup

For original Maslow users (Arduino Mega), you need to be running Holey firmware (51.28 or later). The magic all happens on the CNCjs side, where a custom Maslow controller translates the necessary codes (yes, it even supports “Work Positions” being different than “Machine Positions”). For Arduino Due users (M2), you’ll need to upgrade to the firmware in the Due firmware repository (see the instructions at the top) – which basically implements the same advanced kinematics which the Holey firmware had.

Software Setup

Look at the Makerverse repository. Carefully read the README, and choose from the appropriate option in the latest release.

- A pre-built Raspberry Pi image (just flash it and go!)

- A Windows installer

- A MacOS installer

- A Docker container

- A systemd service for Linux servers

- … if all else fails, the launch script should work on all devices (run bin/launch --help)

Once the app has started and loaded in your web browser, you’ll be on the Home screen. Create a new workspace, choosing the correct port and baud rate. If the workspace is not created, go back to the Hardware step and make sure you’ve installed the correct firmware, and that you’ve chosen the correct baud rate.

When the workspace opens, it will automatically detect which Maslow you have:

If you did not change firmware or frames (i.e., original Maslow already had Holey firmware), you should not need to re-calibrate. It should “just work.”

New Calibration I’ve implemented a non destructive calibration technique. You get to it by pressing the “Bullseye” icon on the Maslow widget. It’s actually just Hoely calibration… without the holes. You measure from the edge of the sled to the edge of the stock. I’ve started to document how it works here.

Once you’ve entered the Edge Calibration results:

UI I have several CNC machines that all run off the same Raspberry Pi. So I got a bit carried away and started upgrading the Makerverse UI. It now supports a tabbed interface, for multiple workspaces, as you saw above. Each workspace maintains its own settings and connection to a CNC machine.

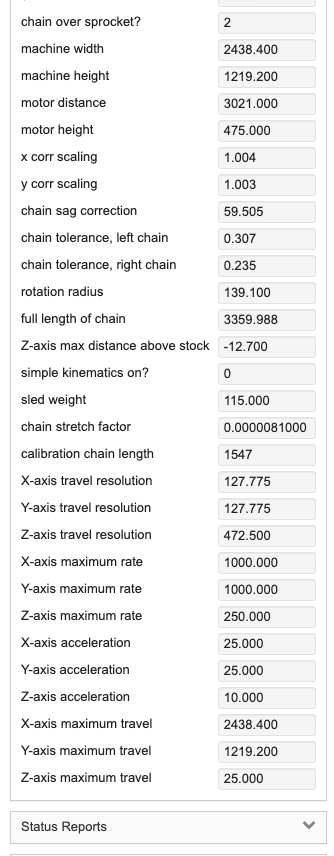

It also automatically parses out the Grbl settings from the controller at startup. This means it can show detailed information about any Grbl device without knowing anything about the firmware.

Testing

So far, I have tested with:

- My original Maslow Jumpstart Kit (Makermade)

- An Arduino Due with a MetalMaslow shield

- An Arduino Due with a M2 shield

To demonstrate the accuracy of calibration with the Maslow Due’s new firmware, calibrated with the new technique, cutting in the bottom 1" left corner.