First cut in 0.75" red oak

Nice!

I’ve been wanting to cut solid hardwood. Can you tell us about the experience (bit type, passes and depth, speed, noise etc)?

This was actually much easier than expected. I used 1/4" up cutting bit (this exact one). 12 ipm surface speed with 0.25" cutting depth. 7 ipm plunge depth. I use a bosch router with variable RPM which was set to ~20,000rpm (setting 4-5). Noise was a bit louder than usual but I tend to adjust the RPM of my router to find the “sweet spot” when cutting. All and all, the settings were not much different than what I use for regular plywood, but check out that grain!

2 cool! 123456 to reply

Just came across this interesting collection of links for CNC furniture plans:

I saw that on the facebook page! Looks like some good stuff.

Table for the wife based on the Opendesk Canteen design.

Opendesk stopped sharing downloads so I had to recreate it in Fusion360.

Exactly why i don’t mind them doing that, most of my projects i didn’t think of myself. But recreating them teaches some cad skills.

Thingyverse is great, but everyone just prints a Groot with their brand-new 3d printer and then struggles to find another use for it.

total beginner here, been wanting to do the same.

are you able to share files? could it be made larger?

LMFAO i apparently clicked the wrong “reply” that question was meant for a connect four game

I converted this area into a sofa - couch conversion. I had planned to use the cnc but the cuts were pretty straight forward.

I helped a friend with donating these signs to a local high school football team. They will be painted with the name and jersey number of the player and staked in their yard.

1/2" plywood, Fusion 360 for CAD/CAM, 3mm pockets, 12mm contour cuts, single pass, max feedrate, 1/4" single flute upcut (great bit btw)

Utilized the whole sheet. You can see some cut quality issues in the lower left corner but nothing the orbital sander couldn’t take care of.

Sign lettering out of 11/32 ACX ply. I only designed and cut the letters and moon, friend of mine did all the mounting and painting.

Used inkscape, fusion 360 and 1/4" bit (and a coping saw for some of the details

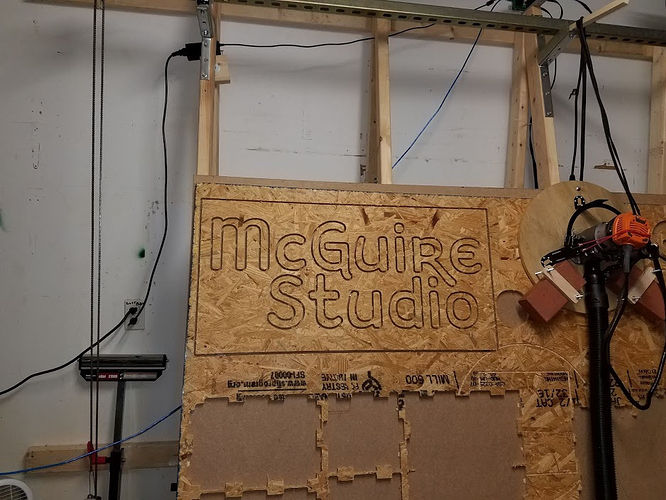

A sign for my garage wall.

Font: Kingthings Hand downloaded from https://www.1001freefonts.com

Still undecided how to paint it…

Edit - All made from scrap pieces. The face is 1/2 in. OSB, left over from my Holey Calibration testing and running a box generator from Easel. The background I used a piece of 1/4 in. underlayment that I slapped on some dark cherry stain on to give it some contrast…

Thank you for your help on this.